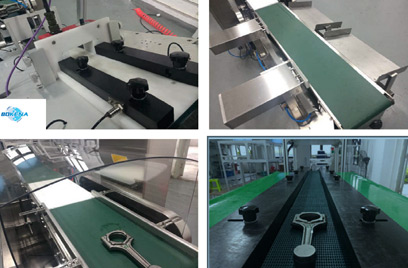

GTET-02 Cylinder Liner Eddy Current Testing Machine

GTET-02 Cylinder Liner Eddy Current Machine Introduction

- The rate of missed standard defect is 0%; the rate of false positives (only misidentified products are judged as non-conforming products) ≤1%.

Detection method

Eddy current testing is to connect the conductor to the coil with alternating current. The alternating magnetic field is established by the coil. The alternating magnetic field passes through the conductor and electromagnetic induction is applied to establish an eddy current in the conductor.

The eddy currents in the conductor also generate their own magnetic field, and the action of the eddy current magnetic field changes the strength of the original magnetic field, which in turn causes a change in the coil voltage and impedance.

When a defect occurs on the surface or near-surface of the conductor, the intensity and distribution of the eddy current will be affected. The change of the eddy current causes a change in the voltage and impedance of the detecting coil. According to this change, the existence of the defect in the conductor can be indirectly known.

Since the shape of the test piece is different and the detection position is different, the shape of the test coil is different from that of the test piece. In order to meet various testing needs, various detection coils and eddy current testing instruments have been designed.

In eddy current testing, the detection coil is used to establish an alternating magnetic field; the energy is transmitted to the conductor to be inspected, and the alternating magnetic field established by the eddy current is used to obtain the quality information in the detected conductor. Therefore, the detection coil is a transducer.

The shape, size and technical parameters of the test coil are critical to the final inspection. In eddy current testing, the type of detection coil is often selected according to the shape, size, material, and quality requirements (testing standards) to be detected. There are three types of commonly used detection coils.

1) Through coil

The through the coil is a coil that detects the sample to be tested and put it in the coil and is suitable for flaw detection of tubes, rods, and wires. Since the magnetic field generated by the coil acts first on the outer wall of the sample, the effect of detecting the outer wall defect is good, and the detection of the inner wall defect is performed by the penetration. In general, the detection sensitivity of the inner wall defect is lower than that of the outer wall. The drawback of thick-walled tubing is that it cannot be detected using an externally wound coil.

2) Interpolated coil

The interposer coil is a coil placed inside the tube for inspection. It is used to inspect the defects of thick walls or the inner walls of the borehole. It is also used to check the quality of the tubes in the ndt inspection equipment, such as the in-service inspection of heat exchanger tubes.

3) Probe coil

The probe coil is a coil placed on the surface of the sample for inspection. It is not only suitable for surface scanning inspection of simple plates, slabs, billets, round billets, bars and large diameter pipes, but also for complex shapes. Inspection of mechanical parts. Compared with the through the coil, the probe coil is suitable for detecting small surface defects due to its small volume and small field action range.

We have eddy current machine for sale, contact us for more details!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Eddy Current Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current testing machine has a calibration device, input compensation parameters, automatic/manual temperature comp... | |

| Application of Ndt Inspection Equipment | Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical... | |

| Magnetic Flux Leakage Testing Equipment | BKN is one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, ndt ultrasonic testing equipment, ... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from the main body of the computer mechanism the handle o... |

Похожие товары

| Plastic Smoke Density Tester F313 | Продавец: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

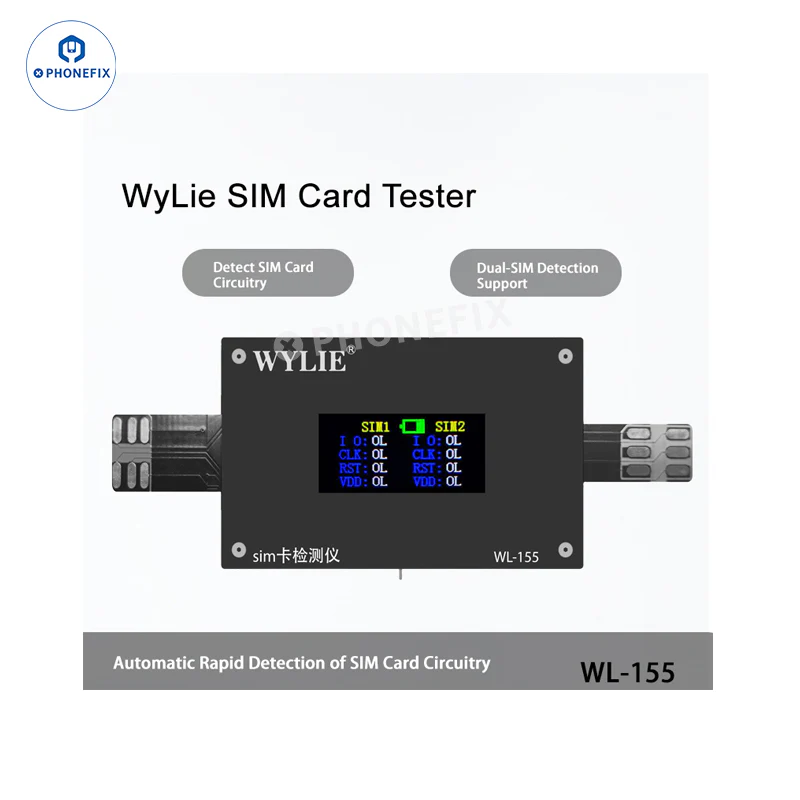

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | Продавец: China PHONEFIX Technology Co., Ltd | Тестер SIM-карт WYLIE WL-155 используется для обнаружения цепей SIM-карт и поддерживает обнаружен... | |

| Высокоточный датчик напряжения HCV1500 | Продавец: Shenzhen Hangzhi Precision Electronics Co., Ltd | Высокоточный датчик напряжения HCV1500 — это датчик напряжения, способный измерять постоянн... | |

| Xenon Test Chamber | Продавец: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Продавец: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... |