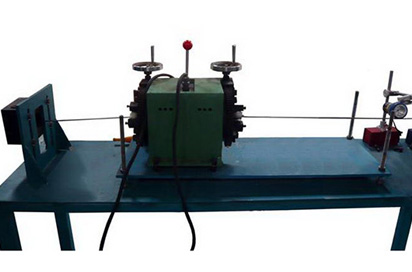

GTET-02 Cylinder Liner Eddy Current Testing Machine

GTET-02 Cylinder Liner Eddy Current Machine Introduction

- The rate of missed standard defect is 0%; the rate of false positives (only misidentified products are judged as non-conforming products) ≤1%.

Detection method

Eddy current testing is to connect the conductor to the coil with alternating current. The alternating magnetic field is established by the coil. The alternating magnetic field passes through the conductor and electromagnetic induction is applied to establish an eddy current in the conductor.

The eddy currents in the conductor also generate their own magnetic field, and the action of the eddy current magnetic field changes the strength of the original magnetic field, which in turn causes a change in the coil voltage and impedance.

When a defect occurs on the surface or near-surface of the conductor, the intensity and distribution of the eddy current will be affected. The change of the eddy current causes a change in the voltage and impedance of the detecting coil. According to this change, the existence of the defect in the conductor can be indirectly known.

Since the shape of the test piece is different and the detection position is different, the shape of the test coil is different from that of the test piece. In order to meet various testing needs, various detection coils and eddy current testing instruments have been designed.

In eddy current testing, the detection coil is used to establish an alternating magnetic field; the energy is transmitted to the conductor to be inspected, and the alternating magnetic field established by the eddy current is used to obtain the quality information in the detected conductor. Therefore, the detection coil is a transducer.

The shape, size and technical parameters of the test coil are critical to the final inspection. In eddy current testing, the type of detection coil is often selected according to the shape, size, material, and quality requirements (testing standards) to be detected. There are three types of commonly used detection coils.

1) Through coil

The through the coil is a coil that detects the sample to be tested and put it in the coil and is suitable for flaw detection of tubes, rods, and wires. Since the magnetic field generated by the coil acts first on the outer wall of the sample, the effect of detecting the outer wall defect is good, and the detection of the inner wall defect is performed by the penetration. In general, the detection sensitivity of the inner wall defect is lower than that of the outer wall. The drawback of thick-walled tubing is that it cannot be detected using an externally wound coil.

2) Interpolated coil

The interposer coil is a coil placed inside the tube for inspection. It is used to inspect the defects of thick walls or the inner walls of the borehole. It is also used to check the quality of the tubes in the ndt inspection equipment, such as the in-service inspection of heat exchanger tubes.

3) Probe coil

The probe coil is a coil placed on the surface of the sample for inspection. It is not only suitable for surface scanning inspection of simple plates, slabs, billets, round billets, bars and large diameter pipes, but also for complex shapes. Inspection of mechanical parts. Compared with the through the coil, the probe coil is suitable for detecting small surface defects due to its small volume and small field action range.

We have eddy current machine for sale, contact us for more details!

在线联系供应商

Other supplier products

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| Steel Pipe Testing | Steel having a hollow section that is much longer than the diameter or circumference. According to the cross-sectional shape, it is divided into ro... | |

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection systemthat uses large-scale imported integrated circuits combined... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP algori... | |

| BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator | Eddy Current Brake for Sale Stimulating the coil makes a magnetic induction to the tested material. The induced electromotive force received by th... |

Same products

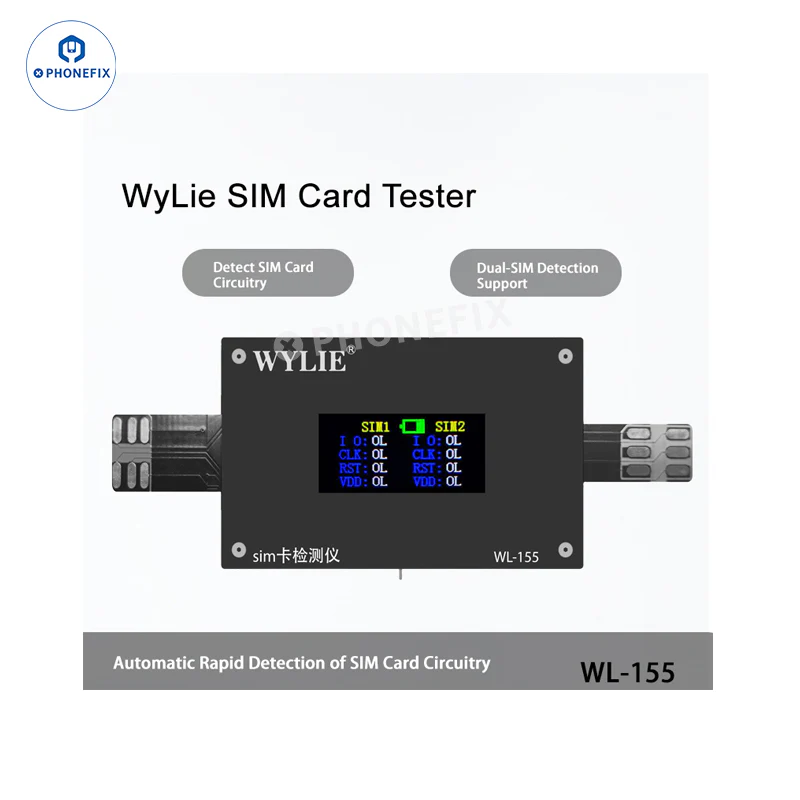

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | 卖方: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM卡测试仪用于检测SIM卡电路,支持iPhone 14/15/16/17 Pro Max和安卓手机的双SIM卡检测。配备LED数字显示屏,支持Type-C充电,即插... | |

| HCV1500高精度电压传感器 | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500高精度电压传感器是一种能够在原边和副边完全隔离的条件下测量直流、交流、脉冲及各种不规则波形的电压传感器。它主要用于对精度要求较高的测量验证和校准领域,以及对灵敏度、稳定性、可靠性要... | |

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... |