UF Membrane Technology

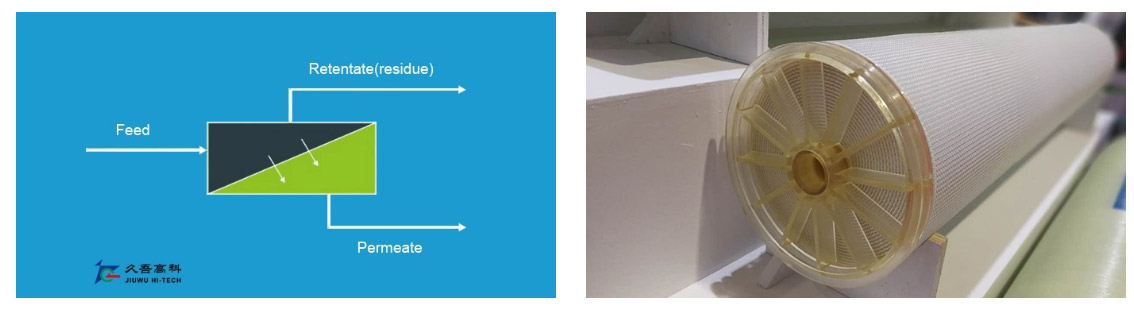

Ultrafiltration (UF) is a variety of membrane filtration in which forces, such as pressure or concentration gradients, cause separation through the semi-permeable membrane. High molecular weight suspended solids and solutes remain in the so-called retentate while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). The pore size of the ultrafiltration membrane is in the range of 0.01μm ~ 0.05μm, suitable for the separation, concentration and purification of macromolecules and small molecules.

Ultrafiltration membranes(UF) can separate substances with different characteristics from the solution, thereby achieving the goal of purification. The main characteristics of ultrafiltration membrane(UF) are

Application of Ceramic ultrafiltration Membrane

UF technologycan be used to remove particulates and macromolecules from raw water to produce potable water. It has been used to replace the existing secondary (coagulation, flocculation, sedimentation) and tertiary filtration (sand filtration and chlorination) systems used in water treatment plants or as stand-alone systems in isolated areas with a growing population.

When treating water containing highly suspended solids, primary (screening, flotation and filtration) and some secondary treatments are often used as a pretreatment stage to incorporate ultrafiltration into the process.

When water recovery is simple, very little processing is often required. However, when more in-depth processing is required, industry standard procedures include the use of UF membrane technology, which means removing the physical solids from the water by passing them through a semipermeable membrane. With ultrafiltration, the solids are primarily captured by the filter and discarded.

Circulating water can also be used in a variety of industrial applications including water supply to boilers or cooling towers, pH control, cleaning equipment, hard beds and vehicles, fire fighting, rinsing or process water for manufacturing industrial lines, toilet flushing, dust control, construction activities Mix with concrete.

Ceramic membranefiltration system is often used to pre-treat surface water, seawater and bioprocessed municipal water upstream of reverse osmosis plants.

Industries that consume large amounts of water or discharge highly toxic wastewater may use ultrafiltration to recover water.

These include chemicals, steel, plastics and resins, paper and pulp, pharmaceutical and food and beverage industries, including soft drinks and canned foods, and electricity, water and wastewater treatment plants.

Ultrafiltration is used to recycle flow or add value to later products and more. In many cases ultrafiltration (UF) is used for prefiltration in reverse-osmosis plants to protect the reverse-osmosis process. Ultrafiltration is an effective means of reducing the silt density index of water and removing particulates that can foul reverse osmosis membranes.

Features of Ultrafiltration Membrane

Ultrafiltration processes are preferred over traditional treatment methods for the following reasons:

No chemicals required (aside from cleaning)

Constant product quality regardless of feed quality

Compact plant size

Capable of exceeding regulatory standards of water quality, achieving 90-100% pathogen removal.

If you are interested in ultrafiltration membrane and want to know uf membrane filter price, please contact us via or directly call us.

JIUWUHI-TECH has many uniquemembraneapplications and more than 50 Patents regarding ceramic membranes, Organic membrane filters, systems and process applications, in areas such as Food & Beverage, Bio-Pharm, Environmental and the Chemical Industry.We sincerely invite and welcome people from all around the world to invest and create more values together.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Nanofiltration Ceramic Membrane Element | Ceramic Nanofiltration membrane is relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-produ... | |

| Organic Membrane | Ceramic membraneand other hi-tech membrane technology serve an important role in our daily life. JIUWUworks to provide our customers with the best ... | |

| SS Membrane Module | The SS ceramic membrane module is designed by different applications. Stainless steel could be used as the material of module/housing, that is, ss ... | |

| SS Membrane Module | The SS ceramic membranemodule is designed by different applications. Stainless steel could be used as the material of module/housing, that is, ss m... | |

| Nanofiltration Ceramic Membrane Element | Ceramic Nanofiltration membrane is relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-produ... |

Похожие товары

| Emerson AMS Trex device communicator TREXCFPNAWS3S | Продавец: 840499 | The Emerson AMS Trex communicator features a 5.7 inch resistive touchscreen display that is easy ... | |

| Flow Control Joints fittings plug valve check valve high pressure pipe | Продавец: Top-end Industrial Manufacturing & Engineering Inc. | Flow control, flow control parts, plug valve, 4130, 4140, 4330, 4340 or as per required. PRODUCT... | |

| Ultrafiltration Ceramic Membrane Element | Продавец: Jiangsu Jiuwu Hi-tech Co., LTD | JIUWU company produces the ceramic ultrafiltration membranes with the pore size 20nm, 50nm and so... | |

| UF Membrane Technology | Продавец: Jiangsu Jiuwu Hi-tech Co., LTD | Ultrafiltration (UF) is a variety of membrane filtration in which forces, such as pressure or con... | |

| SS Membrane Module | Продавец: Jiangsu Jiuwu Hi-tech Co., LTD | The SS ceramic membrane module is designed by different applications. Stainless steel could be us... |