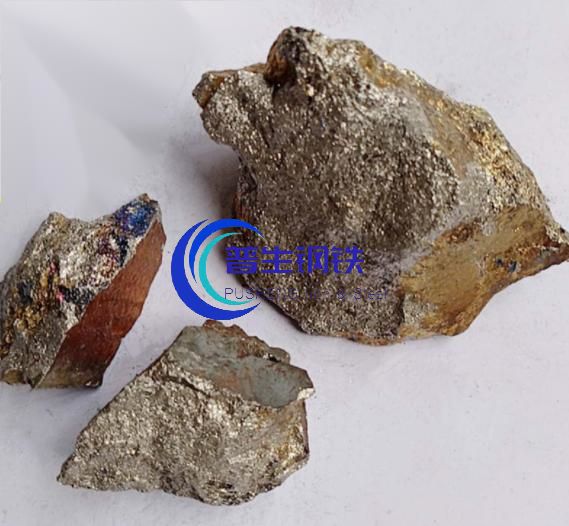

Cobalt Metal

Cobalt Metal for Sale

Cobalt is a shiny steel-gray metal, relatively hard and brittle, ferromagnetic, heated to 1150℃ magnetic disappear. The combined valence of cobalt is 2 and 3. It does not interact with water at room temperature and is stable in humid air. It is oxidized to CoO when heated to more than 300℃ in the air, and burned into Co3O4 when white hot. The fine cobalt metal minor powder produced by hydrogen reduction can spontaneously ignite into cobalt oxide in air.

Specification of Cobalt Metal

|

Chemical Composition |

||||

|

Co:99.95 |

C: 0.005 |

S<0.001 |

Mn:0.00038 |

Fe:0.0049 |

|

Ni:0.002 |

Cu:0.005 |

As:<0.0003 |

Pb:0.001 |

Zn:0.00083 |

|

Si<0.001 |

Cd:0.0003 |

Mg:0.00081 |

P<0.001 |

Al<0.001 |

|

Sn<0.0003 |

Sb<0.0003 |

Bi<0.0003 |

||

Application of Cobalt Metal

Cobalt metal is mainly used to make alloys. Cobalt-based alloy is the general term for an alloy made of cobalt and chromium, tungsten, iron, and nickel. The wear resistance and machinability of the tool steel with a certain amount of cobalt can be significantly improved. Starlite carbide with cobalt-50 or more will not lose its original hardness even if heated to 1000℃. Today, this kind of carbide has become the most important material used between gold-cutting tools and aluminum.

Production Process of Cobalt Metal

The methods of extracting cobalt from cobalt-containing materials can be divided into full fire process, full wet process and combined fire and wet process. Modern cobalt extraction mostly uses a combined process.

(1) Full fire process. It was widely used before the 1940s, and now only the Panda cobalt plant in Zaire uses electric furnace to melt copper and cobalt alloys.

(2) Full wet process. It mainly includes the pressurized acid leaching, ammonia leaching, sulfuric acid leaching, nitric acid leaching and chlorination leaching of various materials containing cobalt.

(3) Joint process. It can be roughly divided into two cases: one is to use sulfation roasting (copper and cobalt concentrate, pyrite), reduction roasting (laterite ore), arsenic removal roasting (arsenic and cobalt concentrate) and other simple fire treatment, and then leaching with acid or ammonia solution; The other is in the process of copper, nickel, zinc and other metals smelting process, cobalt enrichment as an intermediate, and then wet treatment.

Due to the complexity of cobalt extraction materials, there is no "standard" or traditional process for cobalt metallurgy. However, no matter what process is used, the final production of cobalt metal generally adopts wet process, which is a major feature of cobalt metallurgy. The production of metallic cobalt from intermediate products containing cobalt obtained by various processes is usually done by drilling electrolysis or hydrogen reduction.

Features of Cobalt Metal

There are 13 isotopes of cobalt, but only 59Co is found in nature. The artificially produced isotope 60Co has a wide range of uses.

The stable crystal shape of cobalt at room temperature is hexagonal dense packing, while the stable structure above 673K is face-centered cubic.

Cobalt is a ferromagnetic substance, similar to iron and nickel in hardness, tensile strength, mechanical properties, thermodynamic properties and electrochemical behavior.

If you want to know more kinds of refractory metals, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Ferro Molybdenum | Ferro Molybdenum Ferro molybdenum is a ferroalloy composed of molybdenum and iron, generally containing 50-60% molybdenum, with a high ferro molyb... | |

| Ferro Tungsten | HSG METAL, as one of ferro tungsten suppliers, provides ferro tungsten for sale. Ferrotungsten belongs to the ferroalloy series. Ferro tungsten ... | |

| Niobium Wire | Niobium wire is cold worked from the ingots to the final diameter. The typical working process is forging, rolling, swaging, and drawing. Niobium... | |

| Chromium Metal | Chrome, white, generally exists in the form of chromium iron compounds in the nature, the iron black or dark brown, block shape, dot, lenticular, r... | |

| Tantalum Tube | Seamless tubes are made by extruding, reducing the size of the tubes, or deep drawing with sheet metal. The manufacturing method of welding is firs... |

Похожие товары

| Ферросилиций | Продавец: Компания Anyang Hongshun Industrial Co., Ltd. | Ферросилиций (FeSi) или ферросилиций — это ферросплав, состоящий из железа и кремния. Ферро... | |

| ферромарганец | Продавец: Компания Anyang Hongshun Industrial Co., Ltd. | Как профессиональный поставщик ферромарганца, мы можем поставлять 65 высокоуглеродистый ферромарг... | |

| Кремний металлический | Продавец: Компания Anyang Hongshun Industrial Co., Ltd. | Кремний металлический (Si Metal), также известный как кристаллический кремний или промышленный кр... | |

| Ферротитан Feti30/70 | Продавец: Inner mongolia pusheng iron & steel Co,.ltd | Ферротитан 30 - это сплав железа с содержанием титана от 30% до 35%. Ферротитан 70 - это сплав ж... | |

| Китай Mn 965 Mn 95 Марганец Металлический в кусках / слитках / брикетах для производства специальной стали | Продавец: Inner mongolia pusheng iron & steel Co,.ltd | марганец отличается высокой чистотой, он используется для повышения твердости металлических матер... |