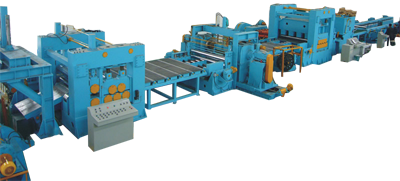

Heavy Gauge Cut To Length Lines

is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to length and blanking. RISHBIN supply full range of cut to length line China according to client’s special requirement by combining different component. Every CTL line is engineered and constructed differently for customers, it is customized designed and built, it is considered when choosing a right CTL line about some specifics like production capacity, running speed, material thickness and width, etc. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

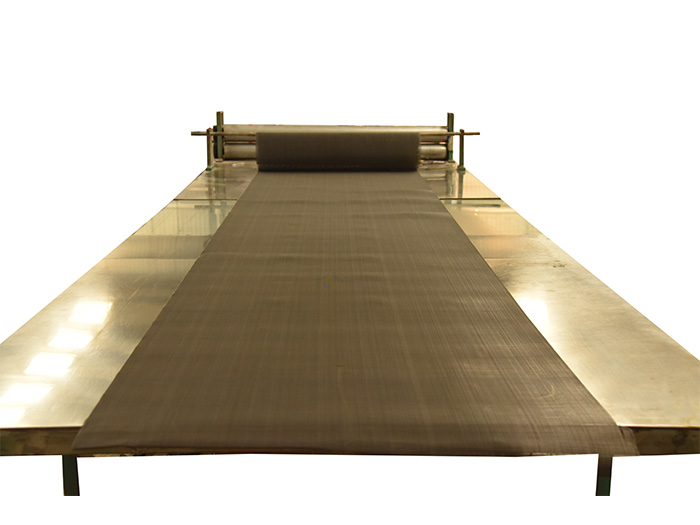

Available raw material for cut to length line is hot rolled steel, cold rolled steel, galvanized steel, pre-painted steel, high tensile steel, stainless steel, aluminum, copper, alloys.

The whole line consists of coil car, double support uncoiler, hydraulic pressing and guiding side device, shovel head, pre-leveler, high precision leveler, cut to length machine, stacker, electric control system, hydraulic system, etc. as well as pendulum middle plate and steering device.

Main Technical Parameters of Heavy Gauge Cut To Length Lines

1.Coil properties: δs≤550MPa, δb≤600MPa

2.Coil thickness: 8mm-25mm

3.Coil width: Max. 2500mm

4.Coil I.D: 508 mm

5.Coil O.D: Max. 2500 mm

6.Coil weight: 40000 kg

7.Line speed: 0-25 m/min

8.Leveler shaft diameter: 260 mm

9.Leveler rollers quantity: 9

10.Cutting length: 800-12000 mm

11.Cutting rate: 8 pieces/min

12.Length tolerance: ±1 mm

13.Diagonal tolerance: ±2 mm

14.Straightening tolerance: ±2 mm/m2

15.Total power: about 250 KW

16.Total weight: about 80 T

RISHBIN heavy gauge cut to length lines are built for speed and ease of use and can produce higher line speeds without experiencing material slippage. Cut-To-Length Line and Blanking Line will make your job easier, cut costs, and increase your profits.

The lines can be supplied with start-stop shears, flying shears. For start stop shear, the sheet is stopped for each cut of the shear. They can cut a variety of lengths and thicknesses. Electric controls are used to stop the leveler drive after the required length has been fed through the shear and to initiate shear action, then the subsequent feeding of the sheared length to the stacker. For flying shear, it’s a high production solution

Here is working process:

Steel coils are transferred by an entry coil car and loaded onto an uncoiler. From uncoiler the strip proceeds through a five-high precision leveler designed to level steel within the desired material gauge range and yield strength. The strip then proceeds through a squaring unit and precision roll-feed unit to the high speed shear, where it is cut to required length. The cut sheet then moves to float sheet stacker where it is stacked on a pallet and is then moved onto the semiautomatic packaging line for wrapping.

Benefits of RISHBIN Cut to Length lines

- Minimal tooling preparations and higher productivity rates

- Energy efficient

- Reduced operating costs

- High in speed and strength

- High input and output rates

- Extreme sheet flatness due to high precision levelers

- Exact cutting accuracy

|

Type |

RS20×2500 |

RS25×2500 |

|

Thickness Range (mm) |

6-20 |

8-25 |

|

Width Range (mm) |

2500 |

2500 |

|

Cutting Length (mm) |

800-12000 |

800-12000 |

|

Cutting Precision (mm) |

±1 |

±1 |

|

Roller Numbers |

9 |

9 |

|

Roller Diameter |

Ф230 |

Ф260 |

|

Coil ID Linear Speed |

Ф610&760m 0~25m/min |

Ф610&760mm 0~25m/min |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Steel Slitting Line... | |

| Light Gauge Cut To Length Lines | is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to lengt... | |

| Light Gauge Slitting Lines | RISHBIN Light Gauge Slitters for pre-painted/coated coils, max. thickness of up to 3mm, max. width of up to 2200mm, and speed of up to 300 m/min.... | |

| Heavy Gauge Slitting Lines | RISHBIN Heavy Gauge Slitters are designed to slit high strength heavy gauge materials. Coils max. thickness of up to 20mm, max. width of up to 2500... | |

| Type of Flying Shearing Machine | Mechanical flying shear is mainly used for rapid shearing processing equipment of metal plates. The following Rishbin machinery will tell you abou... |

Похожие товары

| Plain Steel Mesh | Продавец: Hebei Jiushen Wire Weaving Co., Ltd | Plain steel wire meshis a kind of wire mesh that woven from various kinds of carbon steel wires. ... | |

| 18650 Nickel Strip Phone Battery Spot Welding Connector Sheet | Продавец: Shenzhen Wikshu Technology Co. | Описание 3GOA высокой чистоты 18650 аккумулятор никель полосы литиевой батареи разъем 1M 5M 10M н... | |

| 26 - я Международная выставка нержавеющей стали в Гуанчжоу | Продавец: GUANGZHOU JULANG EXHIBITION DESIGN CO., LTD | 2026China(Guangzhou)International Metal &Metallurgy Exhibition THE 26thCHINA(GUANGZHOU) INTE... | |

| Прямая труба из хромоникелевого сплава центробежного литья | Продавец: Нанкин Xinshuo Механическое оборудование Лтд | Прямая труба из хромоникелевого сплава центробежного литьяДля получения дополнительной техническо... | |

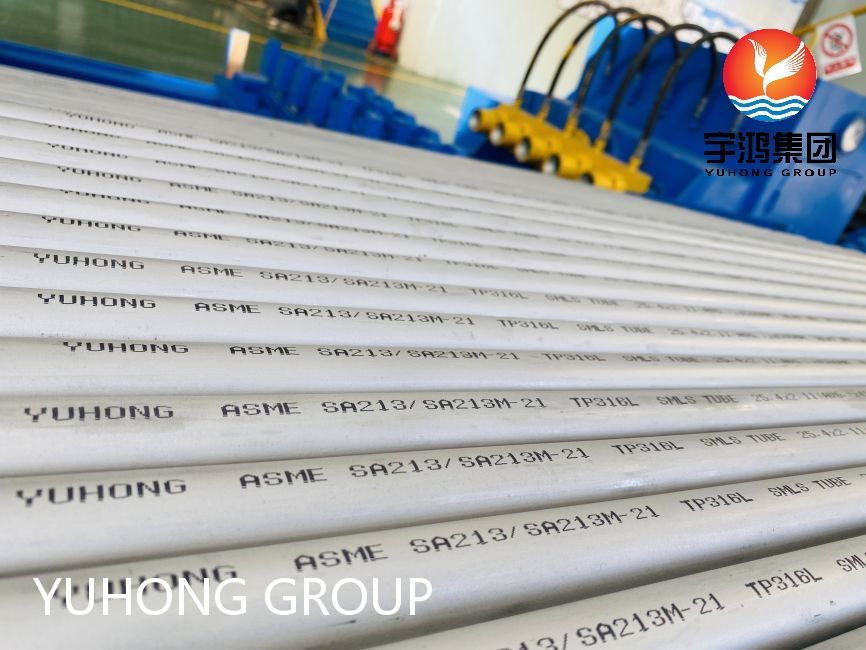

| STAINLESS STEEL PIPE/TUBE | Продавец: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STAINLESS STEEL PIPE/TUBE Stainless steel pipe/tube is one of the most widely used in manufactur... |