Best price of clear liquid silicone rubber

Two components part A and part B, the mix ratio is 1:1 belongs food grade and medical grade silicone rubber, have widely application like cosmetics, medical treatment, construction industry, toys industry, health care products, baby care products, lifecasting products etc.Non-toxic, non-smell, safe touch with skin. They start curing when you mixed them evenly, it can cure at room temperature or fast cure by heating, very easy operation.

|

Type |

Color |

Hardness shore(A) |

Mix ratio |

Viscosity (cps) |

Elongation (%) |

Pot life (min) |

Cure time (h) |

Shrinkage (%) |

|

XRSIL- TP10 |

transparent (customized) |

0-10 |

1:1 |

1000-3000 |

400-600 |

20-30 |

2-3 |

≤0.1 |

Note:

Viscosity, operating time,curing time, hardness and color can be adjusted with the customers requirements.

According to the customer needs curing speed B component to adjust the amount of addition, for curing speed, may be appropriate to add more B component. For colloidal sticky, may be appropriate to reduce the B component.

Features:

1.Have good liquidity, high temperature resistance, corrosion resistance, and high tensile and tear strength, small shrinkage rate, higher rolling over time.

2.Low shrinkage rate, not emit low molecular crosslinking process, so the volume, shrinkage rate is less than 0.1%.

3.Without being limited by the product thickness, depth of curing.

4.This product has excellent resistance to high temperature, the temperature can reach -60-120degree.

5.Food grade, avirulent insipidity, through the FDA food grade certification and ROHS testing.

6.Liquidity is good, easy perfusion; Can room temperature curing and heat curing, easy to operate.

Operation guides and precautions:

The A component and B component by weight ratio of 1: 1 fully mixed, it is recommended to use a static mixer.

Mixing process, pay special attention to try to avoid mixing in the air. Large-scale production and processing, it is recommended to use vacuum mixing, metering and batching equipment.

Exhaust In order to ensure that the product is dense and non-porous, the mixture must be thoroughly aerated into the air. Generally only need to impose 45Torr (28 inches of mercury) residual pressure for a few minutes. As the material expands as it evacuates, its container size is at least 4 times the volume of the mixed material.

Coating The recommended coating method is a roll-on knife coating method. Recommended coating thickness of 0.1mm to 0.5mm (100g / m2-500g / m2). If you want a better elasticity, you can paint thicker. Once the two components are cured, the curing reaction takes place immediately. The operating time can be adjusted from 10 to 120 minutes at 25 ° C (77 ° F). Curing reactions also occur at room temperature; however, heating accelerates the reaction rate.

- We are happy withXinRunliquid silicone rubberand quality. I’ve also been very happy with your best service, let’s continue discussions and work on more. --- Mike (from NY,USA)

- 100% love the liquid silicone. I will be ordering more this week. ----Ahmad(from SA)

- We are very pleased with the quality ofRTV-2 silicone rubberand the performance.------Richard from Holland

- theRTV-2 silicone rubberhas arrived and is excellent------Mike from Malaysia

- I have selled someRTV molding siliconefor my customer, they are very happy, so thank you-----Adam from Morroco.

A. high duplication times and no deformation

B. Good fluidity and good operability and good for pouring method.

C. Excellent mechanical properties, in particular tear strength and tensile strength.

D. Excellent flexibility and it’s easy to demould.

E. High temperature resistance.

F. Range of catalysts allows to fulfill requirements for various

Package:

Part A base silicone: 5kg, 20kg/drum, 25kg/drum or 200kg/drum

Part B CA30 Curing Agent: 250g, 800g/bottle, 1kg/bottle

Shipping:

For sample trial we accept shipping by courier or by air

For batch order usually shipping by sea as cost effective

Dongguan Xinrun Silicone New Materials Co., Ltd.-Xinrun Group Limited was established in 1996,is a production,research and sales of large-scale Chemical materials enterprises from Taiwan. Our Taiwan brand is “Xie Chemical”, was founded in 1980. We have a professional technology and sales team with rich experience to offer service for you and your company.

We have the most molding and casting mold making materials, such as Tin cure silicone rubber, platinum cure silicone rubber,urethane rubber, silicone putty, food grade silicone, LSR injection Rubber, life casting silicone, encapsulation & display silicone, for reproduction of any original models and casting Concrete, plaster, polyurethane, epoxy resin, polyester resin, foam, wax and more.

Welcome customers to choose our products. Please don’t worry about how to choose the products, just tell us what you need, we will help you find a good buy.Thank you.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Best price of clear liquid silicone rubber | Product Description Two components part A and part B, the mix ratio is 1:1 belongs food grade and medical grade silicone rubber, have wide... |

Похожие товары

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | Продавец: ШЭНЬЧЖЭНЬ ИНИБАБА ТЕХНОЛОДЖИ КО., ЛТД. | платиновый отверждаемый силиконовый каучук протез руки ноги ухо продукт жидкий силикон Описание ... | |

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | Продавец: ШЭНЬЧЖЭНЬ ИНИБАБА ТЕХНОЛОДЖИ КО., ЛТД. | life casting food grade silicone rubber soft sex doll two parts liquid silicone Description Tw... | |

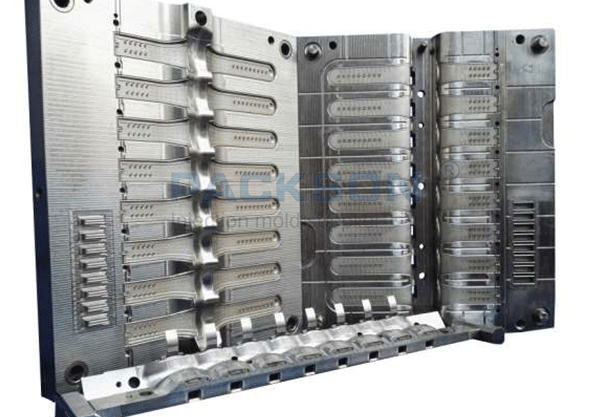

| Silicone Rubber Mold | Продавец: Packson Mold Co.,Ltd | Silicone rubber is a kind of elastic material, which is widely used in industry and family. It ha... | |

| Embossed Silicone Rubber Wristbands/Bracelets Bulk | Продавец: Yppromotion | In addition to those ordinary wristband types, YP Promotion also has a novel technology that can ... | |

| SILICONE BRACELET | Продавец: Yppromotion | The silicone bracelet is made of solid silicone rubber pressed by an oil press. Wholesale persona... |