grinding balls(forging ball and casting ball)、 grinding rod

GRINDING STEEL BALLS (STANDARD: YB/T 091-2005)

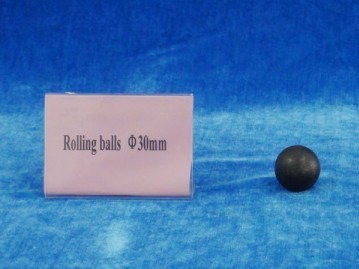

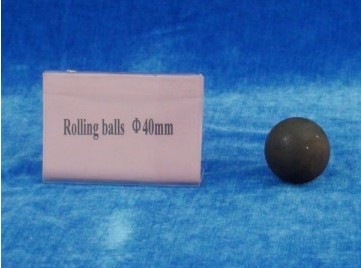

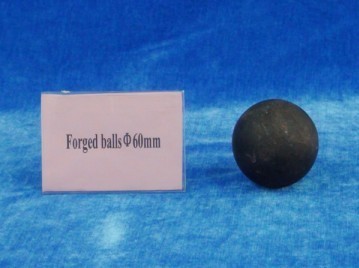

Forged steel grinding balls:

Suit Equipment: both drying and wet ball mills

Tech Specs:

The forged plant operates four production lines and sources input barstock directly from HM rolled grinding balls.

It offers a hardness of ≈65HRc in surface, slowly decreasing towards the core.

Diameters available: 20 - 15Omm (1½” --5″ ).

Key Benefits:

Improved wear resistance due to quenching and tempering..

Steady milling conditions due to wear reduction in wear rate.

It is the best-suited solution to fight wear: it is highly resistant to both abrasion and impact.

BRAND Materials C Mn Si Cr S P Mo Ni

HM B-1 50MN 0.58-0.65 0.85-1.2 0.17-0.37 0.2-0.4 ≤0.035 ≤0.035

HM B-2 60MN 0.75-0.8 0.8-1.0 0.15-0.25 0.55-0.6 ≤0.03 ≤0.03

HM B-3 65MN 0.55-0.6 0.7-0.8 0.17-0.37 0.9-1.1 ≤0.03 ≤0.03 0.05-0.1 0.01-0.05

HM B-4 75Mn 0.45-0.55 0.7-1.0 0.17-0.37 ≤0.03 ≤0.03

HM B-5 75MnCr 0.68-0.75 0.8-0.9 0.17-0.37 0.4-0.5 ≤0.03 ≤0.03

HM B-6 75MnSi 0.7-0.9 0.8-1.02 0.1-0.4 0.7-1.05 ≤0.02 ≤0.02 0.03-0.15 0-0.05

HM B-6A 75MnSi 0.95-1.03 0.92-1.0 0.2-0.3 0.4-0.6 ≤0.02 ≤0.02

HM B-7 Wear-resistant Alloy 0.65-0.75 0.9-1.0 0.17-0.37 0.7-0.9 ≤0.02 ≤0.02 0.05-0.1 0.1-0.2CASTING ALLOY GRINDINGBALLS(STANDARD:GB/T

Suit Equipment: cement drying grinding mills

SIZE: 20mm-120mm

BRAND Material C Si Cr Mn S P

Special-1 Cr-22-32% 2.0-2.8 ≤1.0 22-32 0.5-2.0 ≤0.06 ≤0.08

Special-2 Cr-17-22% 2.0-2.8 ≤1.0 17-22 0.5-2.0 ≤0.06 ≤0.08

Special-3 Cr-15-17% 2.2-3.0 ≤1.0 15-17 0.5-2.0 ≤0.06 ≤0.08

Special-4 Cr-11-14% 2.2-3.2 ≤1.0 11-14 0.5-2.5 ≤0.06 ≤0.08

Special-5 Cr-5-10% 2.1-3.2 ≤1.2 5-10 0.5-1.5 ≤0.06 ≤0.08

Special-6 Cr-1.5-3% 2.2-3.5 ≤1.2 1.5-3 0.5-1.5 ≤0.06 ≤0.08

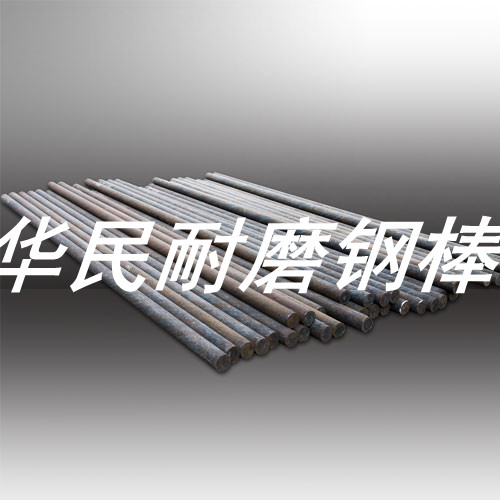

GRINDING STEEL RODS

HUAMIN is the only supplier of steel rods products by heatment in the CHINA.

Suit Equipment: Rod mills.

Tech Specs:

It is a hot rolled rod of high carbon and chromium alloyed steel.

It offers a hardness of ≈55HRc in surface, slowly decreasing towards the core.

Diameters available: 40 - 10Omm (1½” - ≈4″ ).

Lengths available: 2,000 - 7,00mm (≈8″ - ≈21″).

Key Benefits:

Improved wear resistance due to optimal distribution of higher hardness over the cross section.

Increased rod lifetime due to more regular wear mechanism along the whole rod length.

Steady milling conditions due to wear reduction in wear rate.

It is the best-suited solution to fight wear: it is highly resistant to both abrasion and impact.

Other supplier products

All supplier products

Same products