Color Masterbatch for Engineering Plastics

Color Masterbatch for Engineering Plastics

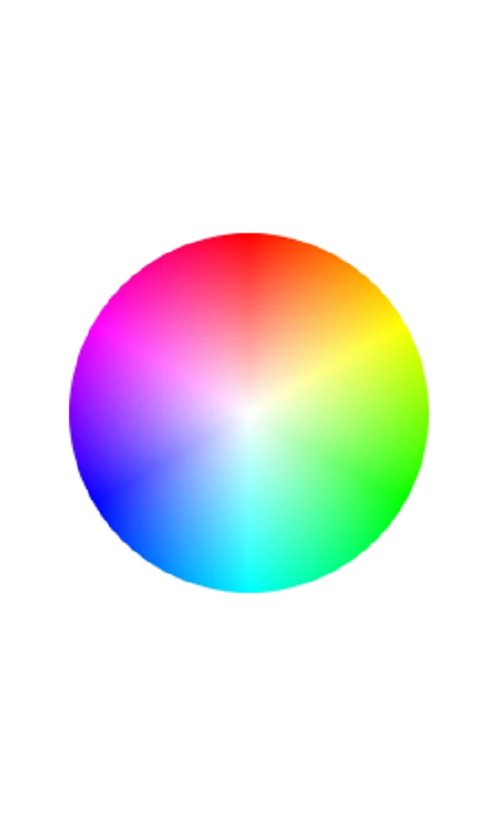

As an engineering plastic company, Anmei serves customers with tailored-making solutions from standard colors to customized colors and functions. There are different types of colour master batchsuch as white masterbatch, black masterbatch, blue masterbatch, red masterbatch, green masterbatch and yellow masterbatch. And what we can offer you are:

THE RIGHT COLOR

THE MATCHABLE PROPERTIES

THE REGULATIONS

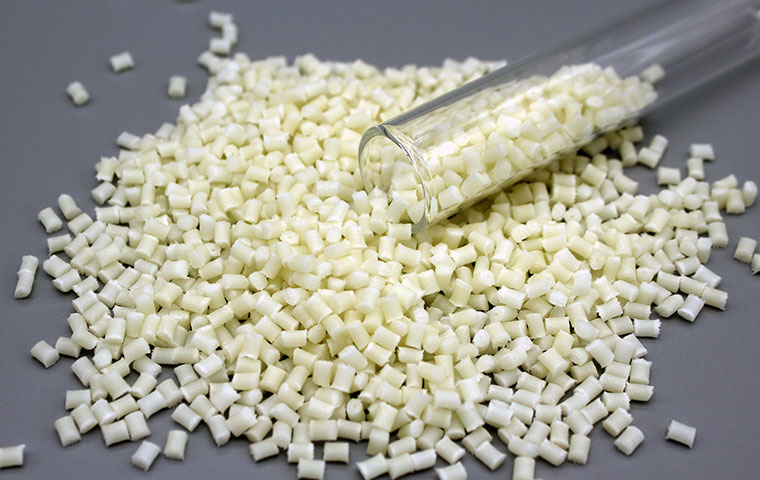

Masterbatch Production

Masterbatch production is a process used in the manufacturing of plastics, where a concentrated mixture of pigments or additives is added to a polymer resin to create a customized color or specific property in the final plastic product.

The masterbatch production process typically involves several steps. First, the polymer resin is melted and mixed with the desired additives or pigments in a high-speed mixer or extruder. The resulting mixture is then cooled, granulated, and packaged for use in the plastic manufacturing process.

The colour master batchis widely used in various plastic products such as films, fibers, and injection-molded products. The use of masterbatches allows for the production of a wide range of customized colors, UV stabilization, flame retardancy, and other properties, making them an essential part of the plastic manufacturing process.

The quality of the master batch colour is essential to ensure the desired final product properties. Therefore, the raw materials, mixing equipment, and manufacturing processes must be carefully selected and controlled to produce a consistent and reliable masterbatch product.

Will the use of masterbatch increase production costs?

The production cost is composed of all aspects.

Master batchescan maintain the superfine pulverized state of the basic pigment to achieve high tinting strength and stability of color matching in order to produce high-quality dense color products, which cannot be achieved by pure toner. And the masterbatch can be 100% put into use without waste. In terms of effect, the masterbatch has a certain economic effect. As one of the reliable color masterbatch manufacturersand color masterbatch suppliers, Anmei provides high-quality color masterbatch at a reasonable price.

Masterbatch ratio and economic value maximization

1/25 is the most widely used ratio. Used in all kinds of plastic products, suitable for all kinds of equipment.

In terms of cost, colour master batch with a low ratio is cheaper, but the proportion of use is large, so the actual cost is high. While a high proportion of color masterbatch, because of the large amount of basic pigments, the proportion of production is small. So the actual cost is low.

Benefits and Advantages of Masterbatch

The masterbatch is composed of colorant, carrier and dispersant. Advantages of using masterbatch:

Making the pigment have better dispersibility in the product.

Ensuring the stability of the product color,and improve the masterbatchconsistency and process stability.

Avoiding environmental pollution because of using cleaner production and economy-saved ingredients.

Easier to addantibacterial masterbatchtechnology, and with safer handling of hazardous materials.

As a color masterbatch supplierand color masterbatch manufacturer, we will do our best to meet all the needs of customers.

If you have needs to buy masterbatch, please contact us.

Send product request

Other supplier products

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, for injection moulding. Typical Application of pa6 6 gf30Heat Stabilized (A2006... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF30is a common nylon material known for its high str... | |

| Masterbatch | We are here to be your reliable partners of Color Masterbatch. Color masterbatches are widely used in polyethylene(PE), polypropylene(PP), polysty... | |

| Nylon66 PA66 Halogen-free FR (A2005X01) for Engineering Plastics | Flame-retardant PA66 is a halogen-free flame retardant engineering plastic made of nylon 66 resin as a base material (other fibers can also be adde... | |

| PA6 GF15 With High Tensile Strength (A1307C, A1317C) for Engineering Plastics | PA6 GF15with high tensile strength is made by 15% glass fiber reinforced, toughened, polyamide 6 resin for injection molding. Typical Applicatio... |

Same products

| Caco3 Masterbatch HD-Ca02 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | Caco3 Masterbatch HD-Ca02 Caco3 Content 82% Mesh 1250 ... | |

| White Masterbatch HD-2601 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | Our factory specializes in manufacturing plastic color master batchesfor many serveces on advance... | |

| Black masterbatch HD-1608 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | We have expert knowledge in production-processes for various applications in the plastics industr... | |

| ELECTRET MASTERBATCH | Seller: Zhejiang Honye New Materials Co., Ltd | ELECTRET MASTERBATCH An Electret Masterbatchrefers to a parent granule that retains charge in a ... | |

| CUSTOM COLOR MASTERBATCH | Seller: Zhejiang Honye New Materials Co., Ltd | CUSTOM COLOR MASTERBATCH Honye offers high-quality custom compounding color masterbatchwith fact... |