Deburring

Deburring is a problem faced by all metal processing enterprises. The size of the burr directly affects the accuracy, quality and life of the product. Most of our products are designed for the polishing of metal parts. The principle is to use abrasive fiber with strong cutting ability, which can be rotated at high speed to remove burrs and won’t damage the workpiece. Our company designed a variety of professional brush, for different shapes, material of the parts, welcome customers to come to consult us.

What arethread deburring brushes?

Burrs are everywhere in the metalworking process. No matter how advanced the precision equipment you use, it will be born along with the product. It is mainly a plastic deformation of the material that generates an excess of iron filings at the processing edge of the material being machined, especially for ductile or tough materials, which are particularly prone to burrs.

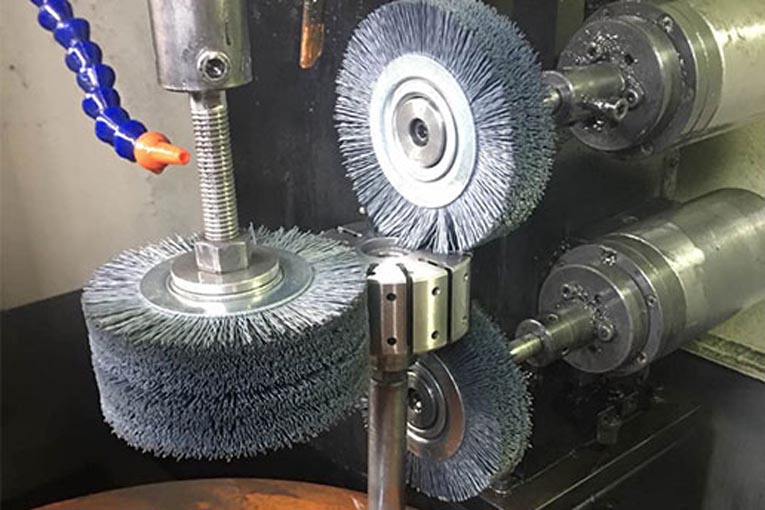

Wire brush deburring machineis the use of special brushes (round brush, bowl brush, wide brush, side grinding brush, bottom grinding brush, straight line brush, bending brush, flexing grinding hole brush, etc.) to grind and deburr the workpiece by driving (or manually) the brush rotation, and also to chamfer, micro-finish and polish the workpiece. This deburring method is divided into dry deburring and wet deburring. Burrs can be divided into metal type brushes and non-metal type brushes. The applicable range of various brushes is selected according to the part shape, material, burr area and size. When deburring, the abrasive brushrotates and makes axial feed, the brush produces grinding on the workpiece and the burr is removed. This method is widely used because of its simple operation, easy movement and low cost.

Surface deburring wire brush

Particularly suitable for automation on production lines, it can be directly installed on CNC machining centers, lathes, robots, special machines, etc. At the same time for burr removal and processing surface polishing, remove the knife cutting knife marks, improve the quality of the processed parts consistent, save man-hours and labor costs. It is especially suitable for processing parts with high surface treatment requirements, such as: cell s, laptop cases, 3C products, aluminum, magnesium alloy, stainless steel materials.

Polishing brushes are used to deburr and polish the appearance of the throw surface. It is necessary to determine the type and characteristics of the brush wire according to the requirements of the difference and the appearance of the brush if the steel plate is strong. For plating and polishing, the ideal wire for brushing should be bronze wire, and the hardness of the accepted wire can be better if it is rust-proofed and deburred for appearance, as is usually the case with metallic materials.

If you want to know more about how to smooth metal edges jewelry, please visit our website.

Send product request

Other supplier products

| Steel Wire Tube Brush | Steel wire tube brushhas strong grinding force and is effective in removing rust, welding slag, paint and other attachments that are not easy to re... | |

| Angle Grinder Wire Brush | Mini Grinder Wire Brush Under many circumstance, due to the limitation of equipment, it is necessary to use manual equipment to grind the parts su... | |

| Deburring | Deburring is a problem faced by all metal processing enterprises. The size of the burr directly affects the accuracy, quality and life of the produ... | |

| Steel Wire Tube Brush | Steel wire pipe brush has strong grinding force and is effective in removing rust, welding slag, paint and other attachments that are not easy to r... | |

| Twist Knot Cup Brush | This is a powerful cutting force brush, can easily remove the most stubborn and hard burr. Can be installed in angle grinder, machine tool, or vari... |

Same products

| Twist Knot Cup Brush | Seller: Shanghai Longguang Industrial Brushes Co., Ltd | Diamond twist knot wire cup brushis a powerful cutting force brush, can easily remove the most st... | |

| End Brush | Seller: Shanghai Longguang Industrial Brushes Co., Ltd | Types of End Brushes End brushis a common small industrial brush, whose structure is simple but ... | |

| Disc Brush | Seller: Shanghai Longguang Industrial Brushes Co., Ltd | Types of Disc Brushes The disc brush is specially used to deal with the surface of metal, such a... | |

| Metal Polish Brush | Seller: Shanghai Longguang Industrial Brushes Co., Ltd | Metal polish brushis a professional, complex knowledge. Different kinds of metal need different a... | |

| Deburring Brushes | Seller: Shanghai Longguang Industrial Brushes Co., Ltd | Deburring is a problem faced by all metal processing enterprises. The size of the burr directly a... |