China Wholesale Granite Diamond Wire Factory Pricelist

Custom segment thickness and shapes can be accommodated based on customer specifications.

Packaging options include white boxes, color boxes, brown boxes, blister packaging, and more to suit your preferences.

Granite is a widely used natural stone, which is favored by the market for its high hardness, strong wear resistance and beautiful appearance. Granite is widely used in architectural decoration, sculpture art and other fields. However, the processing of this material faces many challenges, especially the efficiency and cost control in the cutting process. In recent years, with the development of science and technology, saw technology has gradually become an important tool for efficient cutting of granite.

Principle of Diamond Wire Saw Technology

Diamond wire saw is mainly composed of high-strength steel wire and tiny diamond particles embedded on it. During the cutting process, the diamond particles grind the surface of the stone through high-speed rotation or reciprocating motion, thereby achieving material separation. Compared with traditional disc sawing technology, diamond wire saw has the following advantages:

- High cutting accuracy: Due to the small diameter of the wire saw, more precise cutting can be achieved.

- Fast cutting speed: The efficient grinding ability of diamond particles significantly increases the cutting speed.

- Less material loss: The grooves produced by wire saw cutting are narrow, which reduces material waste.

- Environmentally friendly: Compared with traditional cutting methods, wire saw cutting produces less dust, which is beneficial to environmental protection.

Application in Granite Cutting

In the field of granite processing, the application of diamond wire saw technology is particularly prominent. It can not only meet the needs of large-scale production, but also show excellent performance in customized processing. For example, in the production of special-shaped stones, carving artworks, etc., granite diamond wire saws can provide higher flexibility and precision.

In addition, for the cutting of large stone slabs, diamond wire saws also show unparalleled advantages. By adjusting cutting parameters such as wire speed and feed speed, the temperature during the cutting process can be effectively controlled to avoid stone damage caused by overheating.

How to Use Granite Diamond Wire Saw?

Using to cut stone or other hard materials is a highly technical job that requires certain operating steps and safety regulations. The following is a basic guide to using diamond wire saws:

Preparation

lChoose the right diamond wire saw equipment according to the type, size and thickness of the cutting material.

lCheck whether the equipment is intact and make sure all parts are in good condition.

lInstall the diamond wire saw to the equipment and ensure that the wire saw is properly tensioned, neither too loose nor too tight.

lInspect the wire saw for damage or wear and replace it with a new one if necessary.

lDiamond wire saws generate a lot of heat during cutting, so an effective cooling system is required to prevent overheating.

lMake sure that the supply of coolant (usually water) is sufficient and the nozzle is correctly positioned to evenly cover the cutting area.

lWear necessary personal protective equipment such as safety glasses, earplugs, dust masks and protective gloves.

lMake sure the work area is clean and free of debris to prevent accidents.

Operation Steps

lFix the material to be cut firmly on the workbench to ensure that it does not move during cutting.

lUse clamps or other fixing devices to ensure the stability and safety of the material.

lSet the appropriate wire speed and feed speed according to the hardness and thickness of the material.

lRefer to the equipment manual or consult a professional to determine the best cutting parameters.

lTurn on the cooling system and make sure the coolant starts to flow.

lStart the diamond wire saw machine and let the wire saw reach the predetermined speed.

lSlowly introduce the wire saw into the material and maintain a steady feed speed.

lObserve the cutting process and make sure the wire saw runs smoothly without abnormal sounds or vibrations.

lCheck the flow and temperature of the coolant regularly to ensure good cooling effect.

lPay attention to the wear of the wire saw and replace it in time if necessary.

lWhen the cutting is completed, slowly stop the wire saw and turn off the machine.

lTurn off the cooling system, clean the work area, and remove the cut material.

Send product request

Other supplier products

| OEM China Diamond Grinding Shoe Suppliers and Manufacturers | Diamond grinding shoes are essential tools in the construction and flooring industries, offering durability, efficiency and versatility. Whether... | |

| 22-38mm Diamond Core Drill Bit Concrete Crown Segment | Product Parameter Material: Diamond powder+ metal powder + Cobalt Application: Reinforced concrete, concrete, bricks, Technology: silver welding... | |

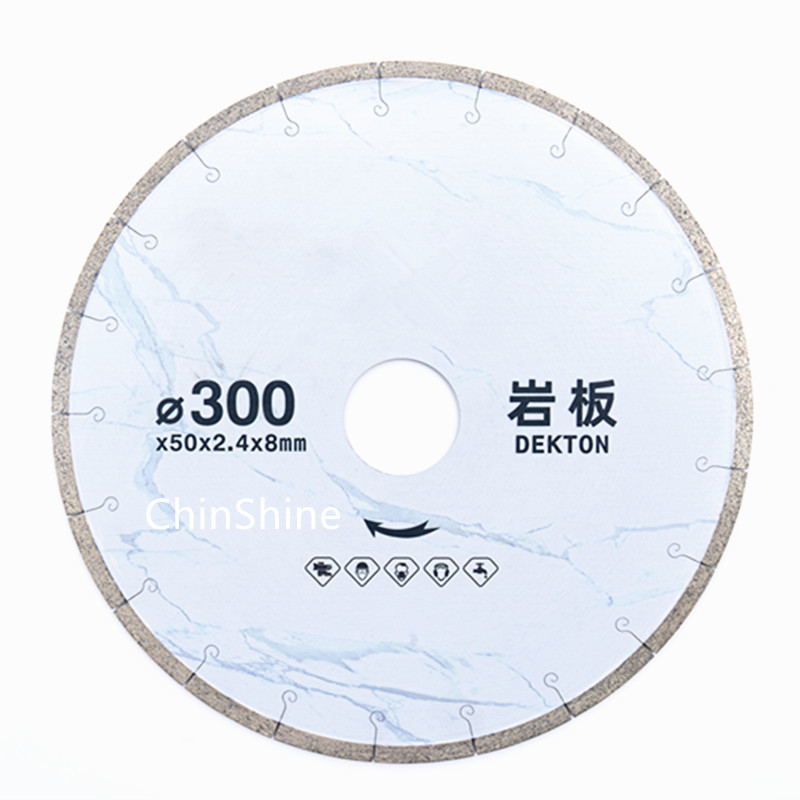

| Best 300mm J-Slot Diamond Saw Blade For Cutting DEKTON | Premium Quality J Slot Tile and Porcelain Diamond Saw Blades feature a sintered, j slot diamond circular saw blade rim design to consistently deliv... | |

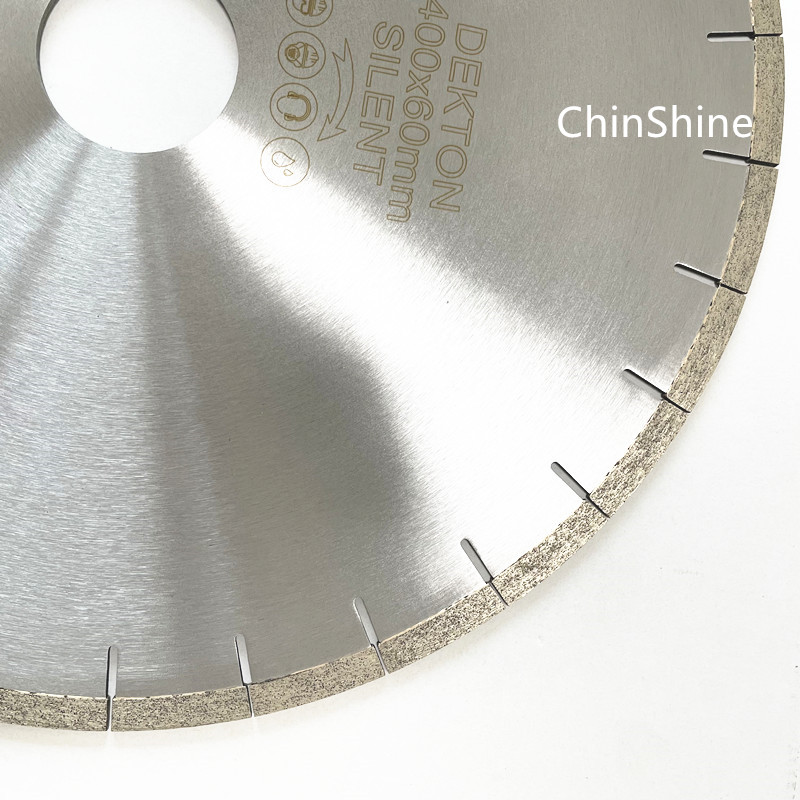

| 400mm Diamond Saw Blade Hard Ceramic Cutting Disc For Dekton | Brand: ChinShine Model No.: Laminam Dekton blade Order(MOQ):1 Product Origin: Quanzhou, Fujian, China Color: All Colors Shipping Port: Xiamen,... | |

| Best Concrete 9 Inch 230mm Diamond Cutting Disc For Angle Grinder | Welding: Laser welding Saw Machine: Angle grinder Cutting: Concrete Segment Type: turbo diamond segment, normal diamond segment, arix segments ... |

Same products

| diamond grit ceramic oscillating multi-tool blade | Seller: Hailian Saw Blade Technology Co., Ltd. | This diamond grit ceramic oscillating multi-tool blade is specifically designed for cutting throu... | |

| Reinforced Concrete Diamond Wall Saw Blade Segment U-Arix | Seller: Xiamen ChinShine Industry and Trade Corporation | Product Parameter Abrasive: Industrial diamond Segment Size: 40*4.8*12mm Activities/Uses: Wet ... | |

| Arix Diamond Wall Saw Blade | Seller: Xiamen ChinShine Industry and Trade Corporation | Product Introduction The wall saw blade is welded by German Dr. Fritsch's full-automatic laser w... | |

| U-Slot Wall Saw Blade | Seller: Xiamen ChinShine Industry and Trade Corporation | The wall saw blade is welded by German Dr. Fritsch's full-automatic laser welding production line... | |

| 800mm Diamond Arix Wall Saw Blades for Concrete Fast Cutting | Seller: Xiamen ChinShine Industry and Trade Corporation | Product Parameter Blade Core thickness: 3.2 or 3.5mm Segment thickness: 4.5/4.8mm/5.0mm Segmen... |