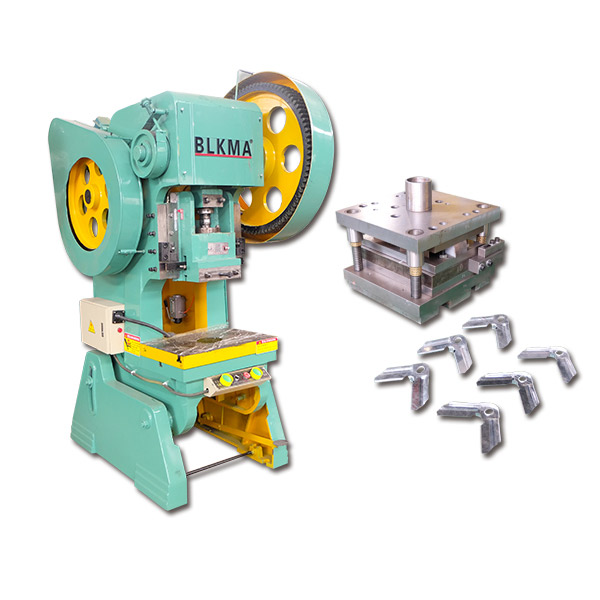

Duct Corner Punching Machine 2019

Duct Corner Punching Machine Performance Features:

|

Model |

Pressure(KN) |

Dimension of die holder(mm) |

Slider stroke |

Slider stroke times |

Power(kW) |

Dimensions(mm) L*W*H |

|

J23-25T |

250 |

40*60 |

70 |

60 |

1220*920*2060 |

|

|

J23-40T |

400 |

50*70 |

100 |

50 |

3 |

1320*970*2380 |

J23 series presses are one of the new generations of plate process and developed by BLKMA team. The press is for cutting, punching, blanking, bending and light stretching work, the puncher can produce duct corner code with the die, and it's also able to punch and cut angle steel with relevant dies. New structure design which means economical and practical. Operation space is wide, and the movable bolster could be moved out of frame to set the die. The structure is simple and the appliance is also beautiful. Duct corner punching machine is the necessary equipment for rectangular duct, BLKMA brand has always been a professional manufacturer of rectangular duct machinery, we can provide customers with very professional steel hole punching machineto help customers more reasonable match and choose the corresponding machines for saving cost and improve work efficiency. At the same time, the rectangular duct machine can provide the corresponding motor power and voltage according to the customer's local power environment to ensure customers in different parts of the world can safely use BLKMA's rectangular duct machine. For many years, the duct corner punching machine is the most efficient products in the duct/pipe processing industry, we provide high-quality products to clients around the world with strong technical strength and years of production experienceand we have steel punching machine for sale. We also many types of duct corner punching machine, like J23-63T, J23-80T, J23-100T, and so on. We will customize the model according to the guest's requirement. Meeting the needs of our guests is our first goal, and the goal we are constantly working on. This duct corner punching machine is designed by us for a long time, and it will be more accurate in the production process, stability has also been greatly improved. And it's much safer and easier to operate. The BLKMA brand is the best choice.

Duct Corner Punching Machine Basic Configuration:

One motor

One slider

One punch die

One electronic box

One control electric system

One cylinder

Send product request

Other supplier products

| Small Electric Shearing Machine | Small Electric Shearing Machine Performance Feature: The small shearing machineis with reduction motor and no gears structure so that the machine ... | |

| U Shape Auto Duct Production Line 5 | It's mainly for TDF / angle steel / C-shaped flange forming with daily processing capability of 1000-2500 square meters. Only with inputting dimens... | |

| CNC Plasma Cutting Machine | CNC Plasma Cutting Machine Performance Features: CNC plasma cutting machineis mainly for automatically lofting and cutting the deformed workpiece.... | |

| Beading Machine 2019 | Line 5/ line 7 beading machines are used to make reinforced ribs in the duct area, and it can output 5 or 7 reinforced ribs at one time. Customer c... | |

| Auto Duct Production Line 2 | Air Duct Machine for Sale Auto Duct Production Line 2 Duct production line 2 can drive blanking for duct and TDF flange forming machine at the same... |