precision injection molding

precision injection molding

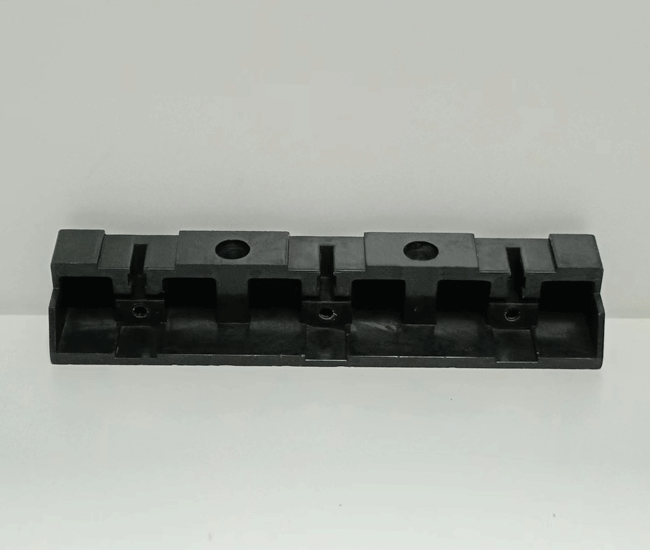

Precision injection moldingis a method demanding unparalleled accuracy in shaping plastic components. Unlike mass production, it’s reserved for cases where precise forms are crucial. These precise plastic parts are commonly used in replacing high-precision metal parts in fields like instruments, electronics, optics, and medical equipment. Due to these stringent requirements, precision injection molding relies on precise molds and machinery, making it a complex process.

The size tolerance of precision injection molds is controlled to less than 1/3 of the product size tolerance. The mold’s precision depends on factors such as the accuracy of cavity size and quantity, cavity positioning, accuracy of parting surfaces, material selection, size tolerance, and more. Factors like the thickness of the base plate, support plate, cavity walls, and runner size are crucial for precision molds. The design engineering is equally vital, with molds typically made from high-strength alloy steel.

Precision Injection MoldingProcess:

Every component developed in precision molding projects must be identified, as their connection is uniform. This ensures a slow, stable, and concentrated precision molding process. The uniqueness of the process for each project emphasizes the importance of mold, part design, material selection, and procedures for successful precision molding.

Precision injection molding machines must control product accuracy and repeatability. The machine should feature a rigid clamping system, part size tolerance control, molding speed, and various components like the screw, screw head, barrel, and collar, all controlled within 0.05 to 0.08mm.

Precision injection molding is a game-changer for industries requiring high-tech, detailed, and complex parts in large quantities. WIT MOLD’s expertise in design and manufacturing ensures a seamless experience in large-scale production. Embrace the precision for a future of cost-effective, efficient, and customized manufacturing.

在线联系供应商

Other supplier products

| UNSCREWING MOLDS | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for producing threaded parts or components with screw-like ... | |

| Two-Shot Injection Molds | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Injection molding are numerous and significant. This cut... | |

| Custom Plastic Molds molding | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile parts and product production methods. With a wealth of... | |

| precision injection molding | precision injection molding Precision injection moldingis a method demanding unparalleled accuracy in shaping plastic components. Unlike mass prod... | |

| Thermoset Molding | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These include epoxies, phenolics, polyesters, and silicones... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |