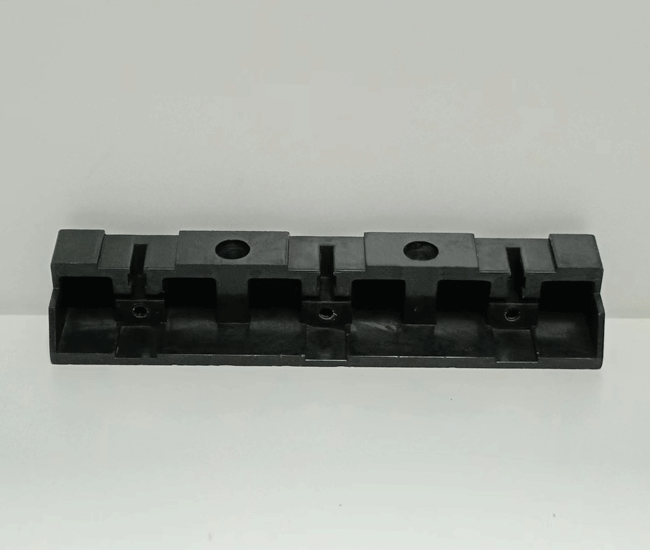

Thermoset Molding

Thermoset Molding

Key Aspects of Thermoset Molding

Materials:

Thermosetting Polymers:These include epoxies, phenolics, polyesters, and silicones. These materials undergo a chemical reaction when heated that causes them to harden into a set shape.

Reinforcements:Often, thermosets are reinforced with materials such as glass fibers, carbon fibers, or aramid fibers to enhance their mechanical properties.

Process:

Mixing and Preparation:The thermosetting polymer is mixed with any necessary additives and fillers to form a compound. This compound is then partially polymerized to a stable, uncured state (often referred to as “B-stage”).

Molding:The compound is placed into a mold. Several molding techniques can be used:

Compression Molding:The compound is placed in an open, heated mold cavity. The mold is closed, and heat and pressure are applied to shape and cure the material.

Transfer Molding:The compound is preheated and then forced into a closed mold through a transfer chamber. This process allows for more intricate shapes and is used for more complex parts.

Injection Molding:Similar to thermoplastic injection molding, but for thermosets. The compound is heated and injected into a mold where it cures.

Curing:The material undergoes a curing process where it is permanently set. This is typically done by applying heat, which activates the chemical reaction that cross-links the polymer chains.

Cooling and Demolding:After curing, the mold is cooled, and the solidified part is removed.

Advantages:

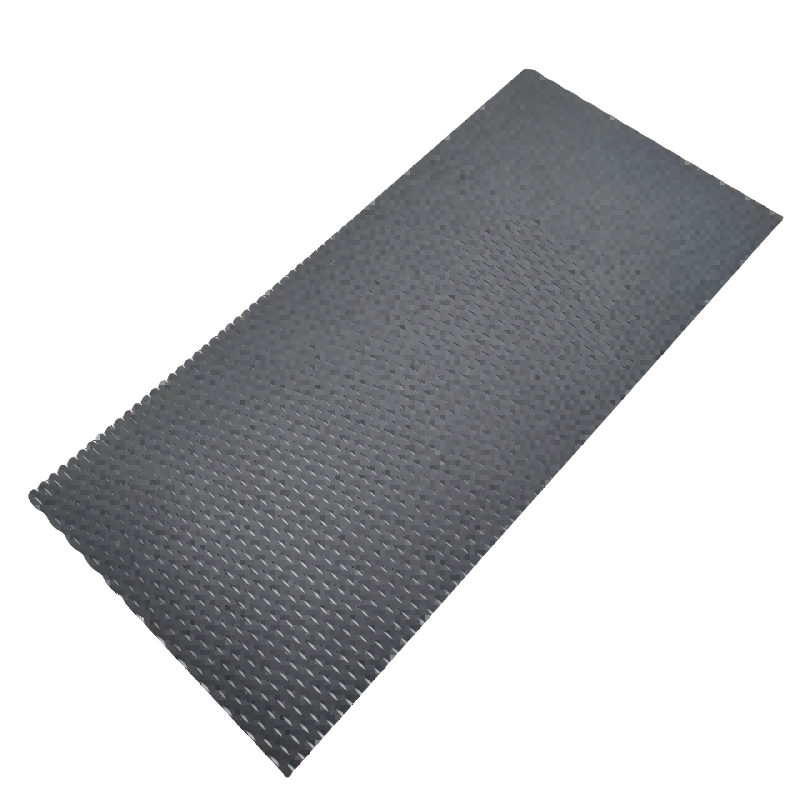

Durability:Thermoset materials are highly durable and resistant to heat, chemicals, and wear.

Dimensional Stability:Once set, these materials maintain their shape and do not deform under stress.

Cost-Effective:For high-volume production runs, thermoset molding can be very cost-effective due to the relatively low cost of raw materials and the ability to produce complex shapes without extensive machining.

THERMOSET TRANSFER MOLDINGApplications:

Automotive Parts:Components like brake pistons, distributor caps, and electrical housings.

Electrical and Electronics:Insulators, circuit breakers, and connectors.

Household Items:Cookware handles, appliance housings, and adhesives.

Industrial Equipment:Gears, pump components, and machine parts that require high strength and resistance to environmental factors.

Challenges:

Processing Complexity:The curing process needs precise control over temperature and pressure.

Waste Management:Once cured, thermosets cannot be remelted or reshaped, leading to potential waste disposal issues.

Tooling Costs:High initial costs for tooling and molds, although these costs are offset over large production runs.

在线联系供应商

Other supplier products

| precision injection molding | precision injection molding Precision injection moldingis a method demanding unparalleled accuracy in shaping plastic components. Unlike mass prod... | |

| UNSCREWING MOLDS | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for producing threaded parts or components with screw-like ... | |

| Custom Plastic Molds molding | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile parts and product production methods. With a wealth of... | |

| Two-Shot Injection Molds | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Injection molding are numerous and significant. This cut... | |

| Thermoset Molding | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These include epoxies, phenolics, polyesters, and silicones... |

Same products

| Thermoset Molding | 卖方: WIT MOLD LIMITED | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These inc... | |

| UNSCREWING MOLDS | 卖方: WIT MOLD LIMITED | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for produ... | |

| dsa anode | 卖方: Baoji Giant Technology Materials Co., Ltd | dsa anode DSA Anode , also known as dimensionally stable anodes, are titanium or niobium su... | |

| mmo electrode | 卖方: Baoji Giant Technology Materials Co., Ltd | mmo electrode MMO Electrode is the process of using electricity to break down water into hy... | |

| anode for printed circuit board | 卖方: Baoji Giant Technology Materials Co., Ltd | anode for printed circuit board Acid electrolytic copper plating is an important step in t... |