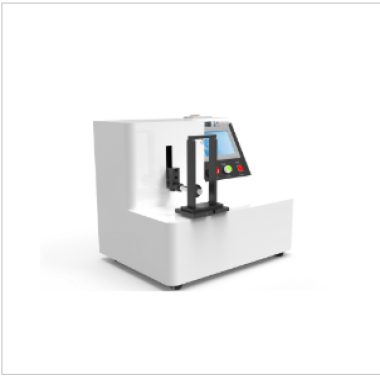

Metal ring friction and wear testing machine

Evaluate the wear resistance of the material:

By simulating the friction process, real-time monitoring of friction, temperature, wear and other parameters to evaluate the wear resistance of Jinzhan materials. This is of great significance for the selection of materials, the optimization of design and the improvement of the service life of products.

Evaluation of lubricant lubrication performance: under the condition of immersion lubrication, the metal ring friction and wear testing machine can be used to evaluate the lubrication performance of various lubricants. By comparing the friction and wear of different lubricants under the same test conditions, lubricants with better performance can be selected.

Study of friction and wear mechanism: The tester can also be used to study the mechanism of friction and wear, including the change of the appearance of the friction surface, the analysis of wear products, and the generation and transfer of friction heat. It is of great significance to deeply understand the friction and wear phenomenon, optimize the design of the friction pair and improve the wear resistance of the friction pair.

Applicable standards:

When testing metal ring friction and wear testing machines, they usually need to follow certain standards and specifications to ensure the accuracy and comparability of test results. Here are some common applicable standards:

GB/T12444-2006 "Wear test method for Metal materials: ring-block sliding wear test" : This standard specifies the wear test method for metal materials under the condition of ring-block sliding friction, which is suitable for evaluating the wear resistance of materials. It contains the terms or guidelines related to the ring block friction and wear test, and specifies the basic technical conditions of the ring block wear testing machine, including the structure, performance, accuracy and other requirements of the equipment.

JB/T 9396-2013 "Ring friction and wear Testing Machine"; The industry standard is applicable to the ring block wear testing machine used to determine the bearing capacity of the moistening agent and the metal wear amount and wear coefficient. It specifies the technical requirements, inspection methods, inspection rules, etc. of the testing machine to ensure the performance of the testing machine and the accuracy of the test results.

SO7148-1982 "Wear testing of Machinery and equipment - General Specification for wear testing machinery" : Although this is an earlier international standard, it specifies a general specification for wear testing of machinery and equipment and may contain basic requirements and guidelines related to ring friction damage testing.

When carrying out the friction and wear test of metal ring blocks, it should be ensured that the selected standard is consistent with the test purpose and requirements, and the test methods and steps specified in the standard are strictly operated. At the same time, it is also necessary to pay attention to the calibration and maintenance of the testing machine to ensure the accuracy and reliability of the test results.

Technical parameters:

Friction speed 0-3000r/min

Pressure range 0-2000N

Friction range 0-1000N

Temperature sensor range 0-200℃

Friction mode Dry friction/wet friction

Specimen size 12*12*19*

Curve display Friction force/temperature/friction coefficient

Spindle radial runout ≤0.01mm

Spindle axial displacement ≤0.01mm

Parallelism between spindle axis and table surface ≤0.02mm

Test data Volumetric wear, mass wear, friction temperature, friction coefficient

Supply voltage 220V/50HZ

Equipment power 2kW

Length, width and height 600mm*500mm*500mm

Equipment weight 75kg

在线联系供应商

Other supplier products

| SI80 Carbon Arc Aging Tester丨SI80 Carbon Arc Aging Chamber | Material aging and fading performance test SI80 carbon arc aging tester, carbon arc aging machine through AC light carbon rod, produce arc light, ... | |

| Helmet Webbing Micro - displacement Abrasion Tester | Main Purposes It is used to detect the abrasion condition of the webbing, the micro - displacement performance of the webbing, and the fatigue lif... | |

| Qinsun Xenotest 220 | Standards ISO 105-B02: Lightfastness testing for colored textiles. AATCC TM16 (Option 3): Accelerated weathering for textiles under controlled co... | |

| Shoe heat insulation testing machine -- sand bath | Standard GB/T 20991: Determines thermal insulation of safety shoe soles under simulated hot surface exposure. EN ISO 20344: European standard for... | |

| Suture Needle Cutting Force Tester | The Suture Needle Cutting Force Tester is a precision instrument specifically used to detect the force required by medical suture needles during th... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |