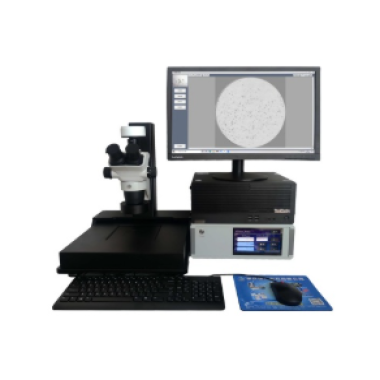

Oxidizing Solids Tester

Product Description

Conforms to UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 34.4.1 Test O.1: Test for oxidizing solids, 34.4.3 Test O.3: Test for oxidizing solids by weight and GB/T 21617-2008 Test Methods for Oxidizing Solids of Dangerous Goods.

Standards

GB/T 21617-2023

GB/T 21617-2008

Product Features

1. It adopts an embedded processor and the Windows CE operating system.

2. With an 8 - inch liquid - crystal touch screen, it can display the test status in real - time.

3. It is compatible with both O.1 standard and O.3 standard.

4. It uses full - automatic photoelectric detection technology to reliably detect combustion phenomena.

5. It has a full - automatic weighing detection by balance, which automatically records the mass loss during the combustion process.

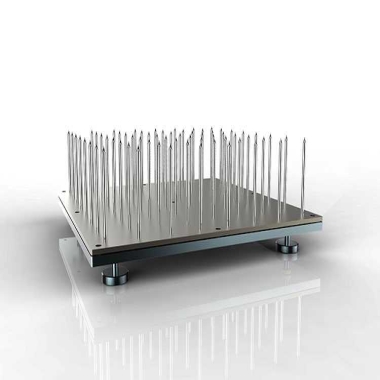

6. It is equipped with a mold made of standard metal wire.

7. It can automatically detect the breakage of metal wires and provide audible and visual alarms.

8. It has a high - precision temperature and humidity detection function to effectively collect environmental temperature and humidity data.

9. During the test process, it displays the running time and test animation images in real - time.

10. It supports remote - controlled ignition to ensure the safety of personnel during the experiment.

11. The test process is fully automated, requiring no manual intervention. It supports functions such as parameter setting, data storage, and report viewing.

12. It is equipped with a temperature and humidity module to monitor the temperature and humidity of the test environment in real - time.

Technical parameters

| Working Environment | (5~40)℃, <85%RH |

| Heating Method | Standard shape inert metal wire heating |

| Heating Wire Power | 150W±2W |

| Detection Method | Infrared sensor array detection method or balance weighing detection method |

| Balance Weighing Accuracy | ±0.1g |

| Ambient Temperature Measurement Range | -10℃~+60℃ |

| Ambient Temperature Measurement Accuracy | ±0.5℃ |

| Ambient Humidity Measurement Range | 5%RH~95%RH |

| Ambient Humidity Measurement Accuracy | ±5.0%RH |

| Timing Display Resolution | 1s |

| Timing Accuracy | ±7ms/Min |

| Test Plate | Made of corundum, 150mm long, 150mm wide, 6mm thick |

| Sample Making Molds | Made of PTFE, inner diameter 70mm, angle 60° cone |

在线联系供应商

Other supplier products

| Salt Spray Testing Machine | Meet the standard: GB/T2423.17 Product Introduction: This type of salt spray test chamber is one of the artificial climate environmental “... | |

| Cleanliness Analysis System | Production: The cleanliness analysis system fully complies with the requirements of standards such as VDA19.1 - 2015. ISO16232. ISO4406. ISO4407. ... | |

| Civil Aviation Aircraft Interior Non-metallic Materials Flame Retardant Property Tester | Compliance Standards FAR25.853 (FAA Airworthiness Standards for Transport Category Aircraft) CCAR-25-R4.853 (Chinese Civil Aviation Regulations App... | |

| ASTM F963 Nail Bed Flammable Tester | G963 Nail Bed Flammable Tester, It is suitable for the burning performance test of cloth toys and filling materials. Perform the flammability of th... | |

| Full-Body Garment Stress Tester,FZ/T 70015 | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exerted by tight-fitting garments or wearable apparel... |

Same products

| Plastic Smoke Density Tester F313 | 卖方: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | 卖方: 上海千实精密仪器 | Product details Furniture flammability tester is mainly used to test the combustion performance ... |