Optical parts processing titanium carbide hard alloy round rods

As a critical material in the field of high-end manufacturing, cemented carbide titanium carbide round rods exhibit excellent corrosion resistance and are highly resistant to rust and degradation in humid, acidic, or alkaline environments. These rods possess a thermal conductivity that is 15% higher than that of conventional tungsten carbide round rods, enabling more efficient dissipation of heat generated during cutting operations and thereby reducing the risk of tool wear caused by overheating. With a bending strength of up to 2500 MPa, the material combines high hardness with a degree of toughness, effectively preventing breakage due to impact during use.

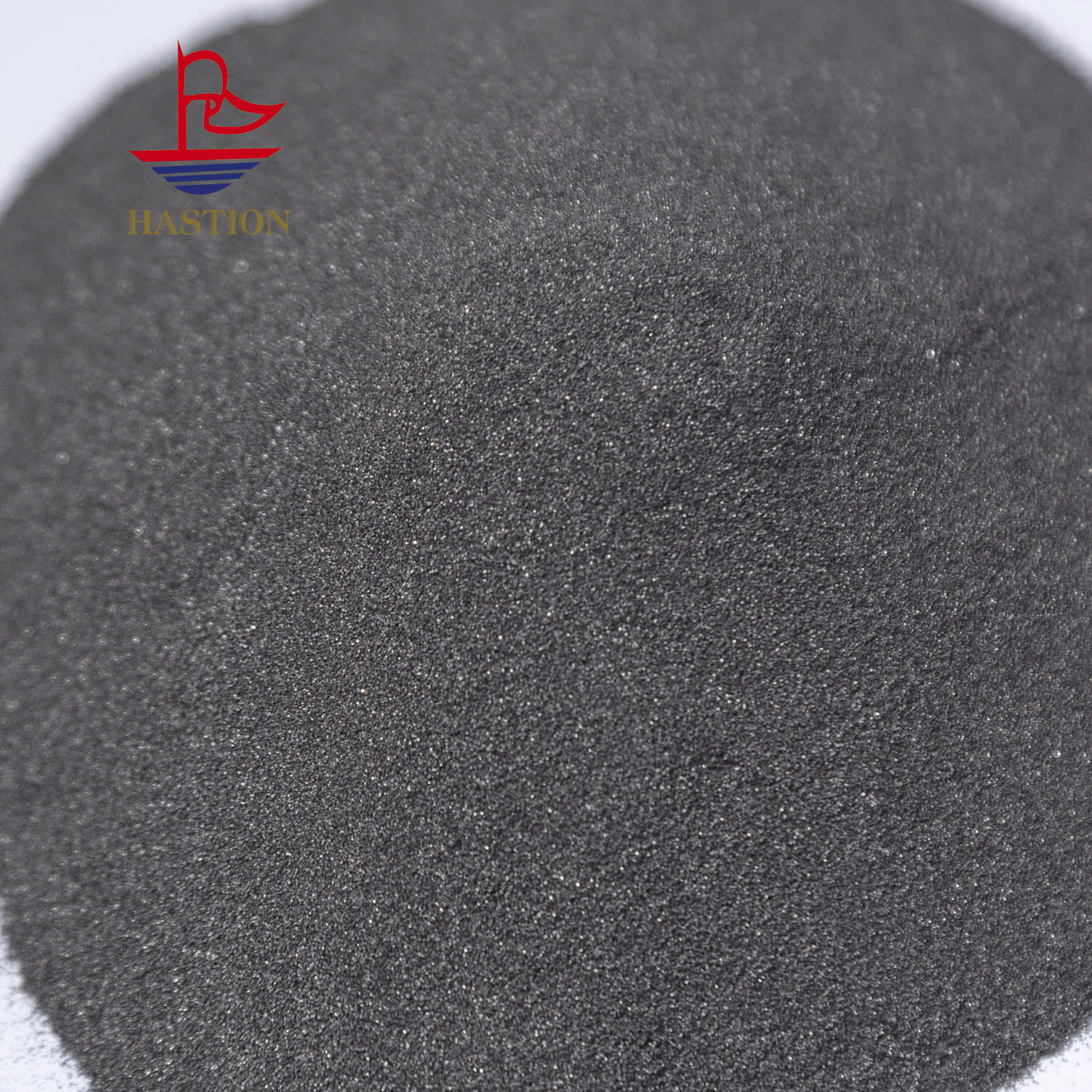

In the aerospace industry, precision machining tools fabricated from these rods are commonly employed in the production of engine components, meeting the stringent requirements of high-precision manufacturing. Cemented carbide titanium carbide round rods are high-performance materials produced through powder metallurgy techniques, with titanium carbide serving as the primary hard phase and cobalt or nickel acting as the binder phase. The hardness of this material exceeds HRC85, and its wear resistance significantly surpasses that of conventional steel. Notably, it maintains stable mechanical properties even under high-temperature conditions exceeding 500°C.

These round rods also demonstrate exceptional dimensional accuracy, with diameter tolerances controlled within ±0.01 mm and surface roughness as low as Ra 0.02 μm. They are ideally suited for the manufacture of precision cutting tools and mold cores. When used to machine difficult-to-cut materials such as stainless steel and titanium alloys, tools made from this material exhibit a service life 10 to 20 times longer than that of high-speed steel tools, thereby substantially improving production efficiency.

Other supplier products

供应产品

Same products