Magnetic Flux Leakage Testing Equipment

What Is Magnetic Flux Leakage

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testingis a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

The basic magnetic flux leakage principleis that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI magnetic flux leakage testing procedureis a highly automated magnetic flux testingtechnology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the magnetic flux leakage sensoras the magnetic flux leakage ndtdetection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

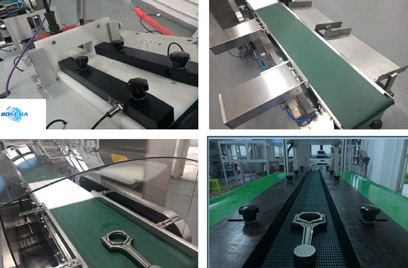

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

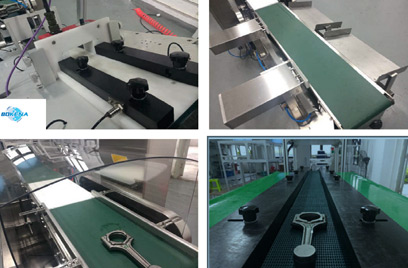

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspectioncan also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance ndt ultrasonic testing equipmentto provide customers with the best quality service.

If you want to know more about eddy current testing, please visit our website.

Send product request

Other supplier products

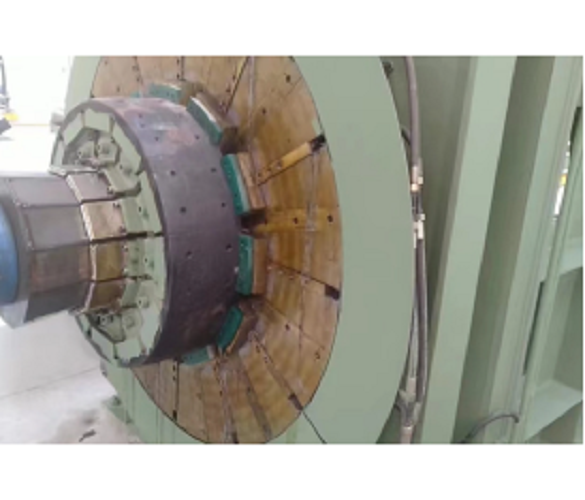

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| Magnetic Flux Leakage Testing Equipment | What Is Magnetic Flux Leakage Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leaka... | |

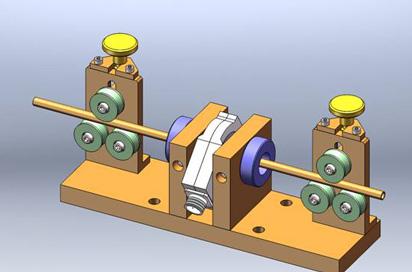

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current sortingmachinehas a calibration device, input compensation parameters, automatic/manual temperature compen... | |

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| LGET-553 Aluminum Tube Eddy Current Flaw Detector | LGET-553 Aluminum Tube Eddy Current Flaw Detector Brief Introduction The aluminum tube is a type of non-ferrous metal which may have one or more... |

Same products

| Disposable Dental Needles | Seller: Shanghai Kohope Medical Devices Co., Ltd. | The dental needles manufacturing, also named disposable dental needles and tooth needles, are ass... | |

| ULTRASONIC STEEL PIPE TESTING EQUIPMENT | Seller: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | Ultrasonic pipe testingwith ultrasonic pipe inspection equipmentrefers to a non-destructive testi... | |

| STEEL PIPE STORAGE RACK | Seller: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | Metal Pipe Storage Racks This ms pipe storage rackmachine serves as a storage system for inspect... | |

| STEEL PIPE ROTATING ROLLER TABLE | Seller: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | This equipment is suitable for the detection and repair welding process in the production of spir... | |

| STEEL PIPE END EXPANDING MACHINE | Seller: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | Pipe expanding machineis a professional equipment for expanding and rounding the end of spiral su... |