RQ-120-B Automatic CNC EDM Notch

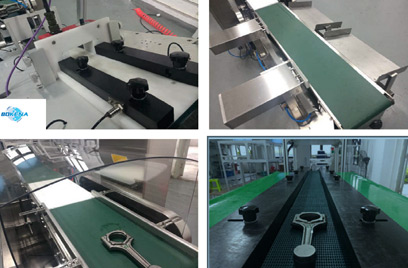

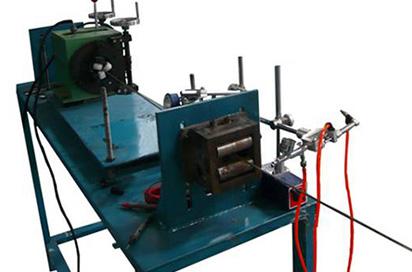

"RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKNAutomation System Co., Ltd. for making inspection sample bars. It can be processed by controlled electric sparking method. It can be used to make longitudinal and transverse standard artificial grooves, rectangular blocks with equal depths and circular holes with equal depths on the inner and outer walls of steel tubes and bars.

RQ-120-B Automatic CNC EDM Notch CutterIntroduction

The core part of the equipment adopts high-quality imported components, using modern advanced digital control and servo technology, the wound-making process is fully automated, with high processing accuracy,fast speed, simple operation and the performance is at the international leading level. The whole instrument is portable, easy to carry, and has low requirement for the environment of steel pipe, bar and pipe carving.

Has the following features:

1) providing controllable electrical pulse generation and modulation;

2) According to the input incision depth parameter, the incision process is precisely controlled by numerical control and servo system;

3) The electronic control system automatically controls the rise, fall and stop of the guide operating mechanism;

4) Control the output of the processing power supply;

5) Adjust the working state of the instrument, such as the processing voltage, current and the position of the operating mechanism, according to the requirements;

6) Real-time precision display of processing speed and engraved depth value;

7) With manual tool setting and automatic engraving function.

Operating mechanism

The mechanism includes CNC servo micro-special motor, precision screw, precision guide rail, electrode fixture and other devices. Under the control of the cutting machine, the cutter head can move up and down to realize precise conveying.

The magnetic seat ensures that the running mechanism is conveniently and reliably fixed on the sample bar to be processed.

Tool guide rod and tool

According to the requirement of engraving internal injury, the operating mechanism extends the engraved tool to the specified length through the guide rod.

The trauma tool is curved according to the outer diameter of the steel pipe, and the internal tool is made according to the inner diameter of the steel pipe to ensure uniform contact between the entire arc surface and the steel pipe.

RQ-120-B Automatic CNC EDM Notch Performance

|

input voltage |

AC220V ±20% 50~60Hz |

|

Input current |

3A |

|

Output Pulse Current |

Max 3A |

|

Output indication |

Touch screen display |

|

Transportation cycle |

1-5000ms |

|

blade width |

|

|

blade length |

1~50mm |

|

Depth of cut |

|

|

Bar specification range |

|

|

Processing of artificial defects |

Various specifications of outer diameter ≥5¢mm |

|

on the outer surface of pipe rod |

Various specifications of pipe inner diameter ≥15¢mm |

Features of RQ-120-B Automatic CNC EDM Notch

|

Precision |

Groove depth error ≤ 5% of groove depth |

|

Groove width error ≤ 5% of blade thickness |

|

|

Isometric rectangle block error ≤ block depth 5% |

|

|

Reliable processing of equal-depth rectangular blocks and equal-depth flat ground holes on |

|

|

the inner and outer walls of steel pipes: including equal-depth rectangular holes and |

|

|

equal-depth flat bottom holes. |

|

If you want to buy a high quality notch cutting machine, please contact us.

As one of ultrasonic testing equipment manufacturers, we will provide more related products for sale ,if you have needs, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| ECT For Automotive And Aerosapce | NDT Application in Automotive Industry: Eddy current testing NDT echnology has been widely used in the detection of metal components in the autom... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP alg... | |

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testing system is a full automatic crack hardness sorter that integrates light, electricity and machinery. The w... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |