Surgical Blade Sharpness Tester

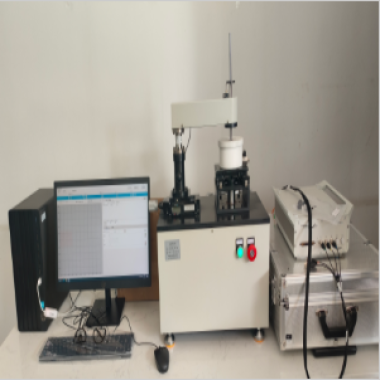

The Surgical Blade Sharpness Tester is a multi-functional testing device featuring a 7-inch LCD touchscreen display, suitable for testing the sharpness of various blades, including surgical blades and utility knife blades. This instrument boasts high-precision cutting and measurement capabilities, supports fully automatic cutting and printing of test results, and offers a flexible operating interface and specialized fixtures to ensure accurate and reliable test data.

Applications

Quality Control in Medical Device Manufacturing: In medical device manufacturing enterprises, the Sharpness Tester for Surgical Blades is used to conduct quality inspections on surgical blades. By simulating the cutting process in surgery and measuring the force required for the blade to cut through standard suture lines or other test materials, it assesses whether the sharpness of the blade meets relevant standard requirements. Only products with qualified sharpness can enter the market, thus ensuring the quality and safety of surgical instruments and providing a guarantee for the smooth progress of surgeries.

- Inspection and Selection by Medical Institutions: Medical institutions such as hospitals also use the sharpness tester for surgical blades to regularly inspect the sharpness of surgical blades. This helps doctors understand the performance of the blades before surgery, select the most suitable surgical instruments, improve surgical efficiency, reduce tissue damage and patient pain during surgery, and at the same time, lower the risks of postoperative infections and complications.

- Quality Inspection in Tool Manufacturing: In tool manufacturing enterprises, the sharpness tester for surgical blades can be used to test the sharpness of blades of different types and uses, ensuring that each batch of blades has stable sharpness performance to meet users' needs.

- Product R & D and Improvement: The sharpness tester for surgical blades is also used in the R & D process of cutting tools. Manufacturers can test blades made of different materials, with different processes and designs, collect relevant data, analyze the relationship between sharpness and materials, processes, etc., so as to optimize product design, improve the sharpness and durability of blades, and launch more competitive products.

- Teaching Practice and Training: In the teaching practice of relevant majors, the sharpness tester for surgical blades is an important teaching tool. It can help students intuitively understand the concept and testing methods of blade sharpness, and cultivate students' practical operation ability and scientific thinking.

Standards

YY 0174 - 2019: Surgical Blades

Features

1. High-Precision Measurement System

Utilizing imported top-brand sensors, the FLY-05DS offers a force measurement range of 0-50N (other ranges customizable), with a force resolution of up to 0.001N and a measurement accuracy of ±1%. This precision far exceeds industry standards, ensuring the reliability and consistency of test results.

2. Intelligent Operation Experience

Equipped with a large-size LCD touchscreen and HMI human-machine interface, the test process curve is clearly displayed. The PLC programmable controller combined with a high-speed processing chip significantly improves system operating efficiency, making operation simple and efficient.

3. Flexible Fixture Design

The FLY-05DS is equipped with professional and user-friendly fixtures that can be quickly replaced to adapt to different blade shapes, meeting diverse testing needs. The stability and adjustability of the fixtures effectively prevent deviations during the testing process.

4. Data Security and Traceability

The instrument features a unique four-level user permission management function, supporting custom permission settings to strictly limit operator access and ensure data integrity. Test data is encrypted and stored, and a comprehensive password protection mechanism is provided to effectively prevent illegal operations, meeting the strict compliance requirements of the medical industry.

5. Efficient Test Speed Control

Equipped with imported precision ball screws, it supports stepless speed adjustment from 1-600mm/min, ensuring sufficient test speed and displacement accuracy to meet the speed requirements of different testing standards.

6. Convenient Result Output

A built-in micro printer can output complete test information, including equipment serial number, sample batch number, experimenter, test results, and time, for easy recording and archiving. The RS232 data interface supports connection to LIMS systems for seamless data integration.

7. System Upgrade and Expandability

The FLY-05DS supports ISP online upgrade functionality and can provide personalized customization services according to user needs, ensuring that the equipment always maintains technological leadership.

Technical Parameters

| Parameter | Specification |

|---|---|

| Testing Range | Force value testing range: 0.1N - 10.0N; error does not exceed ±0.01N |

| Blade Types | Capable of testing various surgical blade specifications, including straight knives, circular knives, and angled ophthalmic knives |

| Testing Rate | Testing speed usually ≤ 10mm/s; error range within ±1mm/min; testing speed can be set via software |

| Other Functions | 1. Equipped with high-precision sensors & measurement system (accurately measures force/displacement in cutting process); 2. Adopts PLC/ARM technology for intelligent operation; 3. Equipped with programmable controller & touch-screen interface (convenient for parameter setting/operation); 4. Displays applied pressure & test data in real time (facilitates observation/analysis); 5. Built-in Chinese-English bilingual input function (suitable for domestic & foreign users) |

Accessoriess

1. One main unit

2. One roll of printing paper

3. One set of clamps

4. One 100g weight

5. One year (warranty)

6. Operating instructions

7. Free lifetime instrument upgrade service according to standard specifications

Test Procedures

— Secure the sample (blade) in the fixture;

— Fix one end of the suture to a winding clamp, and attach a 100 g weight to the other end of the suture, ensuring the suture is horizontal, and fix it to another winding clamp;

The sample is moved vertically downwards at a speed of no more than 10 mm/s to cut the middle part of the suture;

When the suture is cut, the instrument's indicator shows the force exerted by the blade to cut the suture.

Each blade should be tested at three points: the front, middle, and back of the cutting edge, and the arithmetic mean should be taken.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Standard pacifier safety tester | Overview In the infant care industry, bottle quality directly impacts infant health. The NPNZ-01 Baby Bottle Mechanical Performance Tester is spec... | |

| Electrochemical Corrosion and Wear Testing Machine | Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace... | |

| Helmets Vertical SpacingInfrared - positioning Tester | The helmet vertical spacing infrared positioning tester is a specialized instrument used to measure the vertical spacing and wearing height of safe... | |

| Conveyor Belt Drum Friction Testing Machine | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction testing machine has extensive application value in mu... | |

| Photo fill light box | Standard CE & FCC Certified: Meets electromagnetic compatibility and safety standards for EU/US markets. RoHS Compliant: Lead-free constructi... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |