UV Aging Test Chamber

The UV aging test chamber is suitable for all kinds of geo-synthetics, such as light resistance, weather resistance and light ageing

The exposure test of the sample was carried out in a fluorescent UV lamp vessel in a controlled environment. It can simulate and strengthen the environmental factors in the natural climate that are affected by light, heat, humidity, and rainfall as the main aging. It can simulate the accelerated test under long term exposure to obtain the results of the weather resistance of the material.

The exposure test of the sample was carried out in a fluorescent UV lamp vessel in a controlled environment. It can simulate and strengthen the environmental factors in the natural climate that are affected by light, heat, humidity, and rainfall as the main aging. It can simulate the accelerated test under long term exposure to obtain the results of the weather resistance of the material.

·JTG E50 T1164The methods of geo-synthetics for highway engineering

·GB/T 14522-93Accelerated weathering test method for plastics, coatings and rubber materials used for machinery industrial products.

·GB-T16422.3-1997Plastics--Methods of exposure to laboratory light sources--Part 3: Fluorescent UV lamps

·ISO4892-3:1994Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps

·GB/T 14522-93Accelerated weathering test method for plastics, coatings and rubber materials used for machinery industrial products.

·GB-T16422.3-1997Plastics--Methods of exposure to laboratory light sources--Part 3: Fluorescent UV lamps

·ISO4892-3:1994Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps

StandardStructures

· Main features: light, condensation, automatic cycle control, real-time monitoring and display

· Light temperature: RT + 10 ℃ ~ 70 ℃

· Condensation temperature: 50 ℃

· Condensation method: steam humidification condensation

· Temperature uniformity: ± 3 ℃

· Irradiation intensity: 0.55W / m2

· Light / condensation cycle: 0 ~ 9999h,59min. It can be set (such as: 4H / 4H or 8H / 8H)

· Lamp center distance: 70mm

· Sample and lamp plane distance: 55mm

· Light temperature: RT + 10 ℃ ~ 70 ℃

· Condensation temperature: 50 ℃

· Condensation method: steam humidification condensation

· Temperature uniformity: ± 3 ℃

· Irradiation intensity: 0.55W / m2

· Light / condensation cycle: 0 ~ 9999h,59min. It can be set (such as: 4H / 4H or 8H / 8H)

· Lamp center distance: 70mm

· Sample and lamp plane distance: 55mm

· UV lamp: UV-A340 or UV-B313 (optional)

· UV wavelength: (UVA) 315 ~ 400nm; (UVB) 280 ~ 315nm

· Lamp life: 1600 ~ 1800H

· Standard test piece: 75 × 150mm or customized according to customer requirements (it can be made for 21 samples)

· Control system: touch screen controller, real-time monitoring friendly interface, easy to use and easy to operate.

· Power supply: AC220V 50HZ 4.7KW

· The structure of the test chamber is made of corrosion-resistant metal material, including 8 fluorescent UV lamp, water tray, test sample rack and touch screen controller.

· Lamp power is 40W and lamp length is 1200 mm. The working area of the test chamber is in the range of 900 × 210 mm.

· The lamp is installed in a row of four rows, installed in two rows, and the lamp is arranged in parallel, and the center distance of the lamp is 70 mm.

· The test sample is fixedly mounted at a distance of 50 mm from the nearest parallel surface of the lamp surface. The test specimen and its support form the inner wall of the box, and their backs are exposed to room temperature cooling air due to the temperature difference between the test sample and the air in the box. So that the test sample surface condensation phase to produce a stable condensation conditions, the test chamber shall be of natural air convection from the bottom of the box through the outer wall of the box and the test sample.

· The water vapor is produced by the low water pan of the heating box. The water depth is not more than 25mm, and the water supply automatic control. The water dish should be cleaned regularly to prevent the formation of scale.

· The temperature of the test chamber is measured by a sensor with a width of 75 mm, height of 100 mm and a thickness of 2.5 mm on a black aluminum plate (blackboard). The blackboard shall be placed in the central area of the exposure test. The measuring range of the thermometer shall be 30 to 80 ° C , The tolerance is ± 1 ° C. Control of the lighting and condensation stages should be carried out separately, and the condensation stage is controlled by the heated water temperature.

· Standard configuration: (1) 12 UV lamp; (2) 21 sets of sample rack

· UV wavelength: (UVA) 315 ~ 400nm; (UVB) 280 ~ 315nm

· Lamp life: 1600 ~ 1800H

· Standard test piece: 75 × 150mm or customized according to customer requirements (it can be made for 21 samples)

· Control system: touch screen controller, real-time monitoring friendly interface, easy to use and easy to operate.

· Power supply: AC220V 50HZ 4.7KW

Technical Parameters

Features

Stable reliable and consistent

· The structure of the test chamber is made of corrosion-resistant metal material, including 8 fluorescent UV lamp, water tray, test sample rack and touch screen controller.

· Lamp power is 40W and lamp length is 1200 mm. The working area of the test chamber is in the range of 900 × 210 mm.

· The lamp is installed in a row of four rows, installed in two rows, and the lamp is arranged in parallel, and the center distance of the lamp is 70 mm.

· The test sample is fixedly mounted at a distance of 50 mm from the nearest parallel surface of the lamp surface. The test specimen and its support form the inner wall of the box, and their backs are exposed to room temperature cooling air due to the temperature difference between the test sample and the air in the box. So that the test sample surface condensation phase to produce a stable condensation conditions, the test chamber shall be of natural air convection from the bottom of the box through the outer wall of the box and the test sample.

· The water vapor is produced by the low water pan of the heating box. The water depth is not more than 25mm, and the water supply automatic control. The water dish should be cleaned regularly to prevent the formation of scale.

· The temperature of the test chamber is measured by a sensor with a width of 75 mm, height of 100 mm and a thickness of 2.5 mm on a black aluminum plate (blackboard). The blackboard shall be placed in the central area of the exposure test. The measuring range of the thermometer shall be 30 to 80 ° C , The tolerance is ± 1 ° C. Control of the lighting and condensation stages should be carried out separately, and the condensation stage is controlled by the heated water temperature.

· Standard configuration: (1) 12 UV lamp; (2) 21 sets of sample rack

◆ Inner box size: D450 ×W1165×H500 mm

◆ Outline dimension: D500×W1300×H1400 mm

◆ Liner material: SUS304# stainless steel plate

◆ Shell material: SUS304 # senior stainless steel plate

◆ Test piece fixture material: SUS304 stainless steel plate

◆ Imported lamp: Two rows of eight pieces, 40W / pieces

◆ Water and consumption: Clean water or distilled water 8 liters / day

◆ Control system: Color touch screen, real-time display irradiation, condensation, radiation intensity, lamp life tired. Chinese input mode, the whole automatic operation.

◆ Liner material: SUS304# stainless steel plate

◆ Shell material: SUS304 # senior stainless steel plate

◆ Test piece fixture material: SUS304 stainless steel plate

◆ Imported lamp: Two rows of eight pieces, 40W / pieces

◆ Water and consumption: Clean water or distilled water 8 liters / day

◆ Control system: Color touch screen, real-time display irradiation, condensation, radiation intensity, lamp life tired. Chinese input mode, the whole automatic operation.

Send product request

Other supplier products

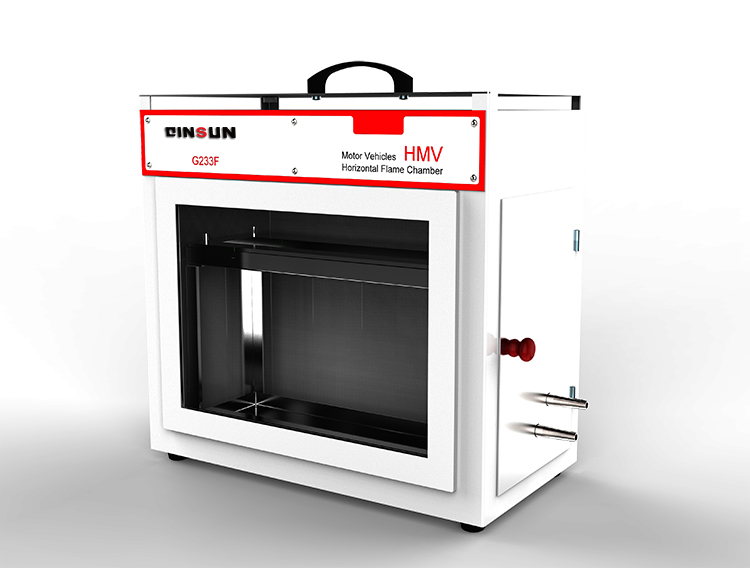

| Horizontal flammability tester | Horizontal Flammability Tester Standards: ISO 3795, FMVSS 302, DIN 75200, SAE J369, ASTM D5132, JIS D1201, AU 169 Applications: The Horizontal Fl... | |

| Random tumble pilling tester | Random Tumble Pilling Tester Standards: ASTM D3512, GB/T 4802.4, ISO 12945.3, JIS L1076-D Applications: Random Tumble Pilling Tester is used to det... | |

| Nonwovens liquid loss tester | Nonwovens liquid loss tester built-in loss of Taiwan and sample fixture for non-woven fabric materials for a specific test fluid slip and loss of p... | |

| Medical mask fire test machine | The device is mainly used in the field of medical protection, and also can also be used fortesting flame retardant properties of other textile coat... | |

| Average Particle Size Analyzer | The Average Particle Size Analyzer has a simple, fast and reliable technique for measuring average particle size. This measurement can not be easil... |