Nanofiltration Ceramic Membrane Element

Ceramic membraneand other hi-tech membrane technology serve an important role in our daily life. JIUWUworks to provide our customers with the best products and solutions!

Ceramic Nanofiltration membraneis relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-product precursors such as natural organic matter and synthetic organic matter. More ultrafiltration membrane system details here!

DETAILS OF NANOFILTRATION CERAMIC MEMBRANE ELEMENT

|

Pictures |

Size |

Poresize |

|

A:4.0mm |

2nm |

|

|

B:30mm |

5nm |

|

|

8nm |

CHARACTERISTICS OF NANOFILTRATION CERAMIC MEMBRANE ELEMENT

lChemical, mechanical and thermal stability

lAbility of steam sterilization and back flushing

lHigh abrasion resistance

lHigh fluxes

lHigh durability

lBacteria resistance

lPossibility of regeneration

lDry storage after cleaning

OVER VIEW OF NANOFILTRATION CERAMIC MEMBRANE ELEMENT

Ceramic nanofiltrationmembrane is widely used in petroleum and chemical industry, medicine, metallurgy and other processes involving harsh systems due to its unique thermal stability and chemical stability, resistance to organic solvents, disinfection, regeneration, and backwashing. In the industrial field, ceramic membrane system has become one of the fastest growing and most promising membrane materials in the membrane field.

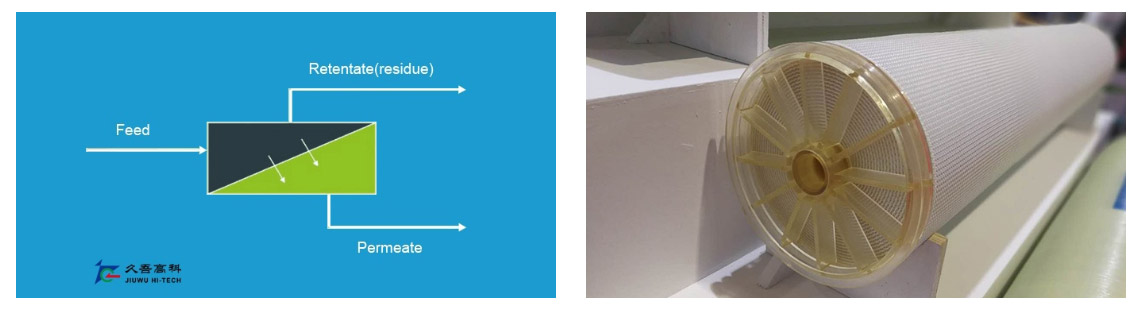

Nanofiltration membrane technology is a new type of pressure-driven separation technology between ultrafiltration and reverse osmosis. It can not only effectively separate the relative molecular mass of 200-1000 by sieving, but also generate the Donnan effect by electrostatic action, with high removal rate for divalent and high valence ions.

In recent years, nanofiltration unittechnology has gradually occupied an important position in the petrochemical, food processing, wastewater treatment, medical technology, and energy industries, and is a common technology for achieving sustainable development.

Nanofiltration membrane materialsare a key core of nanofiltration technology. Ceramic nanofiltration membrane has excellent thermal stability, chemical stability, high mechanical strength, acid and alkali resistance, microbial erosion, chlorine and other oxidizing substances, anti-pollution, etc. It has become the fastest growing and most developed in the membrane field and one of the prospective membrane materials.

APPLICATION OF NANOFILTRATION CERAMIC MEMBRANE ELEMENT

In petrochemical and chemical production, the application of the catalyst is very extensive, and it is generally necessary to separate the product and the catalyst after the reaction. As one of the nanofiltration membrane suppliersand nanofiltration membrane manufacturers, we offer many high quality products. Ceramic nanofiltration membrane has good heat resistance, chemical solvent resistance, and good mechanical strength. It adopts cross-flow filtration method in catalytic reaction solid-liquid separation and has the advantages of nanofiltration, acid and alkali resistance, solvent resistance, etc. The coupling can fully improve the efficiency of the reactor, high separation precision, and can separate the nano-scale catalyst.

Ceramic nanofiltration membrane has excellent performance such as pollution resistance and long life and is widely used in the field of chlor-alkali chemical industry. Using efficient "cross-flow" filtration, it is difficult to achieve results and advantages with other refining and filtration technologies.

Compared with traditional organic membranes, ceramic composite nanofiltration membranes have the unique advantages of high separation precision, guaranteed filtrate quality, high flux filtration, high product yield, low wastewater, low cleaning frequency and no need for additives. It can realize desalting and pre-concentration of target products and has been successfully applied to biological enterprises such as glutamic acid, citric acid, itaconic acid, and vitamin C.

The integrated process with ceramic membrane + organic membrane as the core is widely used in: oily water filtration system, metallurgical wastewater treatment, chemical wastewater treatment, paper mill wastewater treatment, large-scale pure water and ultrapure water preparation, zero discharge of power plant brine.

The integrated process technology with ceramic nanofiltration membrane as the core has the unique advantages of high separation precision, short process, acid and alkali resistance, high-temperature resistance and pollution resistance. It is widely used in industrial flue gas desulfurization, blast furnace solid-gas separation and automobile exhaust gas treatment. Wait.

The ceramic nanofiltration membrane can effectively remove impurity ions in the slurry and efficiently prepare ultrafine ultra-pure nano-powder. At present, it has been applied to the purification of nano-powders such as nano-catalysts and ultra-pure non-ferrous metals. It can also be used in the purification process of nano-materials such as lithium batteries and graphene so that the impurity components in the production process can be removed in time, which is beneficial to the improvement of product yield.

Send product request

Other supplier products

| Microfiltration Ceramic Membrane Element | The ceramic microfiltrationmembrane element ( MF membrane) is made from alumina and zirconia which is an asymmetric membrane structure with multi-c... | |

| SS Membrane Module | The SS ceramic membrane module is designed by different applications. Stainless steel could be used as the material of module/housing, that is, ss ... | |

| Non-Alcohol Beer And No Alcohol Wine | Wine Separation and Extraction System Ideal Choice for wineries And Beer Product Overview JS-WSU-M2serie products are specially designed tome... | |

| UF Membrane Technology | Ultrafiltration (UF) is a variety of membrane filtration in which forces, such as pressure or concentration gradients, cause separation through the... | |

| Nanofiltration Ceramic Membrane Element | Ceramic Nanofiltrationmembrane is relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-produc... |

Same products

| YC160W Wheel excavator YC160W | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |