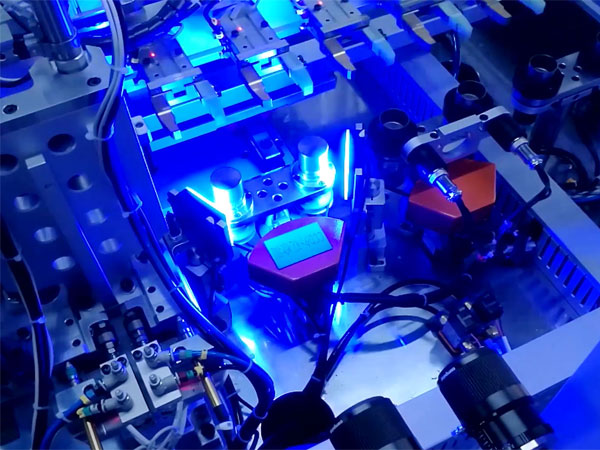

Automotive rocker arm assembly machine

Yiheda automation is one of the best industrial assembly automation companies, as an expert custom automation company, specializes in designing and manufacturing the custom automation solution to customers.

Rocker arm assembly machine: rocker arm is part of automotive engine. The machine stations including: rocker arm oil hole check, width check of rocker arm manufacturing process, needle check, shaft length check, riveting, pushing force check, roller flexibility check, roller parallelism check, card assembly, laser marking, lubricating, cylinder assembly, cylinder check and product unloading. Rocker arm belongs to the rocker arm mechanismof engine, which responsible for closing the air gate. Cam wheel shaft drive rocker arm, it is to control the air flow gate open to realize the inlet and exhaust air of engine.

Engine rocker arm assembly machine advantage:

Material shortage indication, reduce manual feeding time

Automatic remove NG parts during feeding

No material jamming, no damage to product, no missing part during assembly

Displacement sensor resolution 0.01mm

Full set of inspection to ensure high quality of products

Laser marking in specified area, printing clear

Related automation solution:

•manipulator

•Automatic feeding

•Assembly machine

•Inspection device

•Laser marking

Machine feature of automotive rocker arm functionassembly machine

To complete product detection and sorting function by multiple detection methods.

The laser marking is clear and accurate.

Machine parameter of Automotive rocker arm assembly machine

Power:AC 220V

Floor space:3550*2550*1800L*W*H

Power:10KW

Send product request

Other supplier products

| Conveyor | The conveyor includes flat belt conveyor, synchronous belt conveyor, plastic chain conveyor, nets chain conveyor, jig straight return conveyor, spe... | |

| Packing | Applying advanced techniques of feeding and handling, flexible conveying, robot integration, visual inspection and laser marking, Yiheda packaging ... | |

| Jig Circular Conveyor | Thejig conveyoris driven by servo motor, the transmission structure can be customized for different loading requirements. With high accuracy and lo... | |

| Visual Inspection | With the combination of lighting, image and data processing, the automated part inspection systems can detect and monitor the production process an... | |

| Jig linear back-flow conveyor | The jig conveyoris driven by motor elastic belt, which can complete high-speed conveying and positioning of multiple stations at the same time. Esp... |