Automotive Part

We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sales service. We have an precision injection moldingprocess with a component load capacity of up to 2 kg in a large machine, carrying out assembly of complex component modules and offer painting and other finishing services all accompanied by the most sophisticated of logistics processes.

As the foundation of the automotive industry, injection molding automotive partsare necessary factors to support the sustainable and healthy development of automotive plastic parts manufacturer.

In particular, the current independent development and innovation in the automotive parts mold industry that is being carried out vigorously and in full swing require a strong component system in automotive plastic injection molding companies. Vehicle independent brands and technological innovation require automotive injection mold parts and components as the foundation, and independent innovation of parts and components has a strong driving force for the development of the vehicle injection molding automotive parts industry.

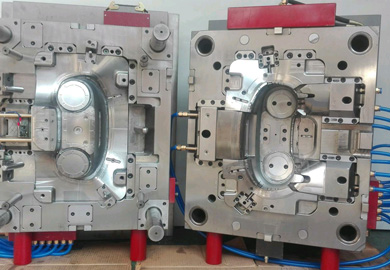

Features of Automotive Injection Mold

Here are three major features of using automotive injection molding for manufacturing injection moulding car parts.

Detailed Features

The automotive plastic injection moldingis subjected to extremely high pressure. Therefore, the plastic is pressed harder against the automotive parts mold. This complex and intricate shapes of plastic injection molding automotive parts can easily be designed.

High Efficiency

Once the automotive parts molds have been manufactured to the customer’s specifications, it is very quick to the actual automotive precision plastic injection moulding. The high production output rate makes plastic injection molding automotive partsmore cost-effective and efficient.

Enhanced Strength

In automotive plastic injection molding, it is possible to use fillers in the injection molds. This filler reduces the density of the plastic which will enhance strength.

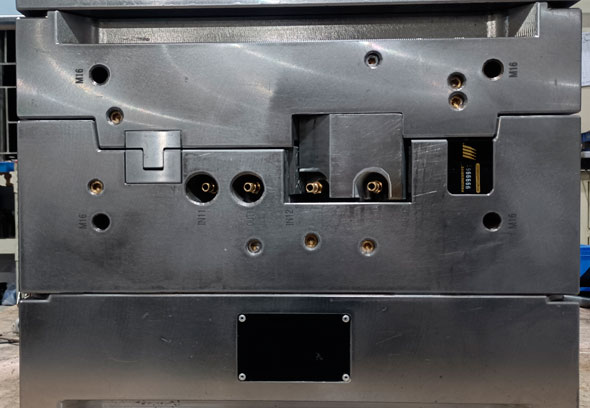

How does Automotive Injection Mold Work?

Automotive injection mold is to first add plastic to the mold, and then the automotive parts mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic in the automotive parts mold is uniformly coated and melted, and adhered to the entire cavity of the mold. On the surface, it is formed into the required shape of injection molding automotive parts and is made by cooling and shaping.

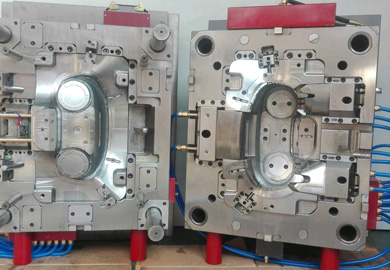

The Specification of injection moulding automotive parts

|

Part material |

ABS + PC |

|

Mould Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

A, B, C, plate P20, others 1.1730 |

|

Tooling life |

100W |

|

Mould standard |

HASCO |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mould quality |

95% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

Send product request

Other supplier products

| Mould Base | After years of development, mold base production industry has been quite mature. Mold manufacturers can purchase customized mold base according to ... | |

| Mould Slide | The slider is a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction during the opening and ... | |

| Mould Design | As an injection molding companies, GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and othe... | |

| Multi Cavity Mould | A multi cavity moldis known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts. Thou... | |

| Mould Base | After years of development, mold base production industry has been quite mature. Injection moulding manufacturercan purchase customized mould ba... |