Metallurgical Furnace

CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold directly to end customers, business partners, and EPC projects. As a professional heavy equipment companies, CIC serves multiple roles, such as, cement machinery suppliers, mining machinery manufacturers, grinding mill manufacturer, rotary kiln manufacturer, rotary dryer manufacturer, sludge dryer manufacturer and so on.

CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blown furnace. Rotary furnace is the main metallurgical equipment used to treat copper and nickel sulfide in nonferrous metallurgical production. The rotary furnace does not need fuel, and only relies on the heat released by the oxidation reaction of iron and sulfur in copper and sulfur with the air blown into the solution to provide all the heat expenditure.

Instruction of Metallurgical Furnace

Rotary refining furnace is mainly used for refining liquid crude copper. The refining operation generally includes four stages: feeding, oxidation, reduction and casting. The product is to provide a qualified anode plate for copper electrolytic refining. Therefore, rotary refining furnace is also called a rotary anode furnace.

The main characteristics of rotary refining furnace are simple structure, large furnace capacity, high degree of mechanical automation, strong controllability, good sealing and low energy consumption. Rotary refining furnace is mostly used in pyrometallurgical refining of large or extra large copper smelters.

Structure of Metallurgical Furnace

The horizontal rotary furnace is a kind of smelting equipment for blowing matte or nickel into coarse copper or high matte in the smelting process of non-ferrous metals such as copper and nickel. Its specification is expressed by the output of each furnace. The furnace body is cylindrical (see Fig. 1), and a furnace mouth is set in the middle for charging, smoke exhaust, slag discharge and discharging. A row of tuyeres is set at the furnace side along the horizontal direction to blow in the air. The lining of the horizontal converter is made of magnesia or chrome magnesia refractory.

Rotary refining furnace is mainly composed of furnace body, supporting device, drive and control system. The main supporting equipment includes combustion device, combustion air system, oxidant, reductant, steam, compressed air, cooling water and process piping (as shown in Figure 2 below)

The cylindrical furnace body is provided with a furnace mouth for charging and discharging copper. The furnace mouth is equipped with a furnace cover. The furnace cover is only opened when charging and discharging copper. The melting period, oxidation period and reduction period are all covered. A small amount of tuyere is set on the side of the furnace body, high-pressure air is introduced in the oxidation period, and the reducing agent is introduced in the reduction period. When the tuyere is not in operation, it is placed above the melt surface. When the redox operation is carried out, the furnace is tilted to make the tuyere embedded in the melt. The rotary refining furnace needs an external heat supply, so it is equipped with a fuel combustion device and exhaust port.

Related Issues of Metallurgical Furnace

What are the masonry methods of the horizontal rotary furnaces?

There are two kinds of masonry methods: rotary furnace body construction method and arch tire construction method. The construction procedure is to build the end wall first, then the circular liner, and finally the furnace mouth. Before the liner of the furnace is built, the driving device of the furnace body must pass the trial operation and be locked; The gap between the end cover of the furnace shell and furnace body should be plugged with asbestos rope. The circular liner and end wall shall be dry laid with staggered joints, and the brick joint shall not be greater than 1.5 mm. The staggered joints between tuyere and furnace mouth shall be wet-laid, and the brick joint shall be no more than 2 mm.

What are the construction preparations for the rotary refining furnace?

The refining furnace is a complete set of equipment in the smelter, which is used together with a smelting furnace and rotary furnace. Generally, one smelting furnace is equipped with three rotary furnaces and two refining furnaces. Due to the simple shape of rotary refining furnace and there are not many brick types involved, except for a small number of special-shaped bricks at the furnace mouth, redox mouth, copper outlet and other parts, most of them are standard bricks, so the construction is relatively simple. The amount of maintenance is not very large, and the number of maintenance is less than that of the rotary furnace. Some fixed construction facilities of smelting furnace and rotary furnace and the working platform around refining furnace can be used.

Before the construction of the rotary refining furnace, the inner diameter of the metal shell, transmission device, supporting device, the control system must be carefully checked, and the furnace can be built only after it is confirmed to be completely normal.

Case Parts of Metallurgical Furnace

|

Equipment |

Type |

Name of Client/Project |

|

Rotary Furnace |

Φ4.4×14.6 |

China Nerin Engineering Co., Ltd |

|

Φ4.2×14 |

China YUN Copper Co., Ltd |

|

|

Φ4.5×14.5 |

China Nerin Engineering Co., Ltd |

|

|

Aluminum Corporation of China |

||

|

Rotary Refining Furnace |

Φ4.5×13.5m |

China YUN Copper Co., Ltd |

|

Chinalco Southeast Copper |

||

|

Lufang Shandong,China |

||

|

Φ4.2×13.5m |

Yuguang Gold & Lead Henan China |

|

|

Qinghai Copper |

||

|

Guangxi Nanguo Copper |

||

|

China Nerin Engineering Co., Ltd |

||

|

China YUN Copper Co., Ltd |

||

|

Φ4.2×13 m |

China Nerin Engineering Co., Ltd |

|

|

Φ2.4×3m |

China Nerin Engineering Co., Ltd |

|

|

Bottom Blown Furnace |

Φ5.2×23m |

Yuguang Gold & Lead Henan China |

|

Φ4.8×23m |

Dongying Lufang, Shandong, China |

|

|

Φ4.4×13.5m |

China YUN Copper Co., Ltd (Yimen) |

|

|

Φ3.6×16m |

Neimenggu Ruifeng Co., Ltd |

|

|

Φ3.6×14m |

China-Tin Group |

|

|

Φ3×14.6m |

Lead Industry in Chenzhou, Hunan Province |

|

|

Φ3×13.5m |

Shandong Fangyuan Non-ferrous Metals Group |

|

|

Φ3×11m |

||

|

Φ3×8m |

Yuguang Gold & Lead Henan China |

Send product request

Other supplier products

| SAG Mill | Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and scre... | |

| Cement Rotary Kiln | Since 1950s, CIC rotary kilnmanufacturer had started manufacturing of pyro processing equipment. These series of pyro processing rotating kilnequip... | |

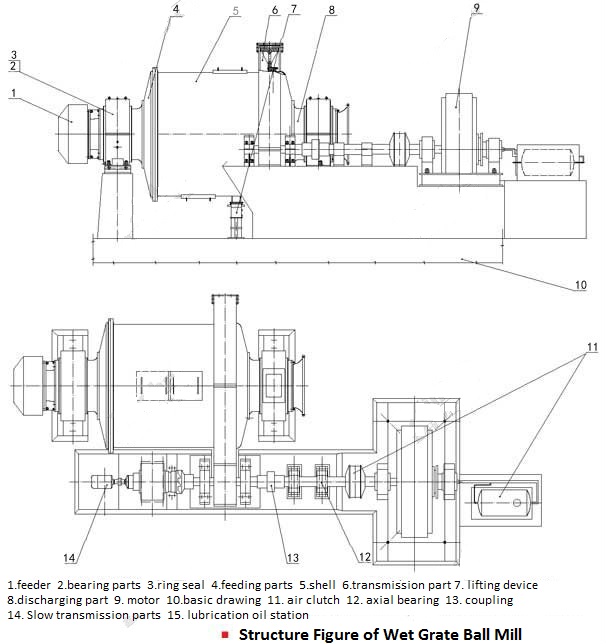

| Wet Grid Ball Mill | Wet ball mill is a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet grid mining ball millp... | |

| SAG Mill | Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and scre... | |

| Wet Grid Ball Mill | Wet ball mill is a kind of energy-saving industrial ball mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill proc... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |