Roller Design and Operating Rules of Cold Roll Forming Machine

Roller Design and Operating Rules of Cold Roll Forming Machine

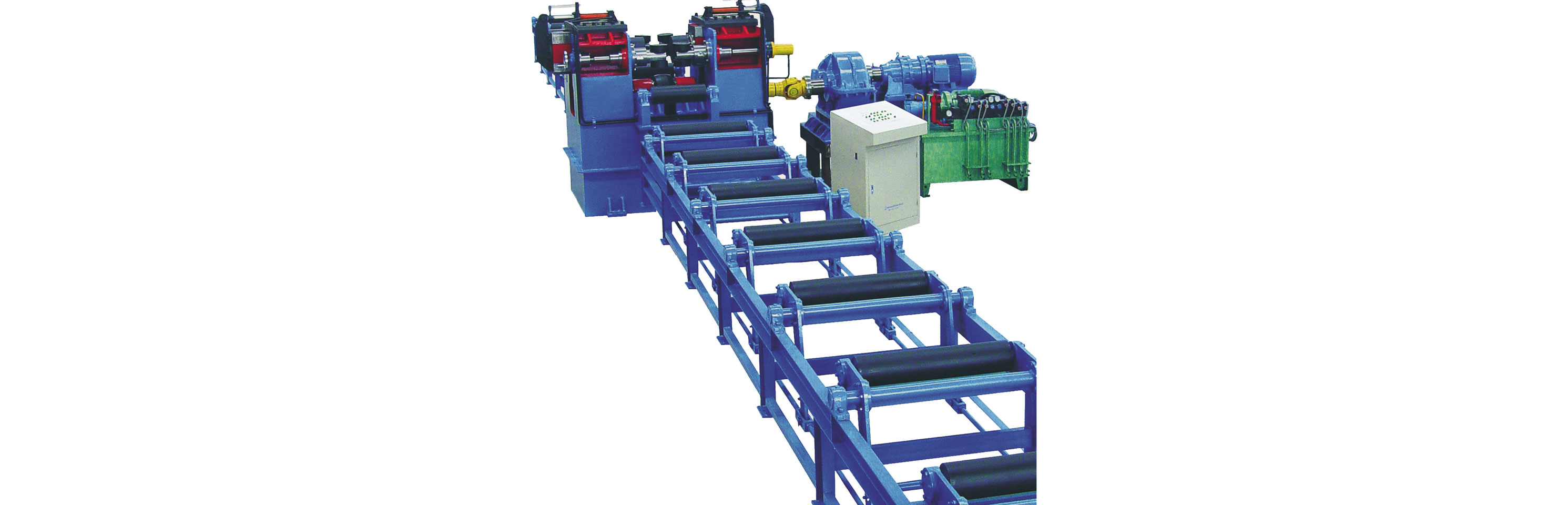

The cold roll forming machinesaves us a lot of time in the production process and also makes our products more perfect and competitive.

Now, let us understand the roll forming machine designand operating procedures of the cold roll forming machine

The details are as follows:

Ⅰ. The roller adopts C12MoV material whose specific strength and hardness are contradictory. The main reason is its wear resistance. The red hardness of C12MoV should be used during heat treatment. After quenching, the hardness can be achieved by two or even three temperings.

Ⅱ. The rollers of the whole line are equally stressed and wear evenly, which prolongs the service life of the rollers.

Ⅲ. In the production, the problem of material deflection in the raceway is often encountered. The reason is actually that the single set of rollers is asymmetry. The large force on the left causes the material to deflect to the right; then the large force on the right causes the material to deflect to the left.

Ⅳ. The arc part of the track is the core part of the slide rail. The arc position after the first few passes is pressed and formed. When the vertical edge is rolled and folded in the later rail, the formed arc shall be effectively protected by the upper and lower rolls or horizontal wheels. Otherwise, the arc position of the material will definitely change during the stretching process. R becomes smaller and becomes a triangle, and the steel ball is not to the bottom. Two-point contact will produce noise. When R becomes larger, the matching rail will shake, and the track will be blurred when the slide rail is used. This leads to uneven force, deformation of the slide rail, and shortened life.

Ⅴ. Ordinary ball bearings have their own gaps, and axial movement cannot be avoided in accurate transmission. The main driving side adopts roller cone bearings to ensure that the radial runout of the main shaft is within and outside 0.04MM, and the main shaft will not move from side to side.

Ⅵ. The method to solve the imbalance of the force: the force design is balanced, the processing is accurate, and the installation and adjustment are convenient.

Ⅶ. The accuracy of roller processing is key. Therefore, a special tool is specially made for inspection under the projector and magnified 20 times.

The cold-formed forming machine must be operated at fixed points according to the operating regulations, and the machine must be lubricated in a targeted manner. The cold-formed machine must be kept clean, and the severely worn parts must be replaced in time. Regularly let maintenance personnel carry out maintenance.

Contact us for more information about jinggong!

Send product request

Other supplier products

| H-Beam Straightening Machine | HBeam StraighteningMachine is mainly used for the angle distortion straightening of heavy H-beam, it adopts hydraulic straightening which will have... | |

| Digital Folder&Slitter | This Digital Folder&slitter folderis the high&new technology product developed by our company and Hayes company from New Zealand. It is int... | |

| Rockwool Continuous Sandwich Panel Production Line | The rockwool sandwich panel production lineis one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system... | |

| PU/PIR Continuous Sandwich Panel Production Line | Continuous pu sandwich panel line, is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, ... | |

| PU/PIR Continuous Sandwich Panel Production Line | Continuous PU Sandwich Production Line, also calledpolyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |