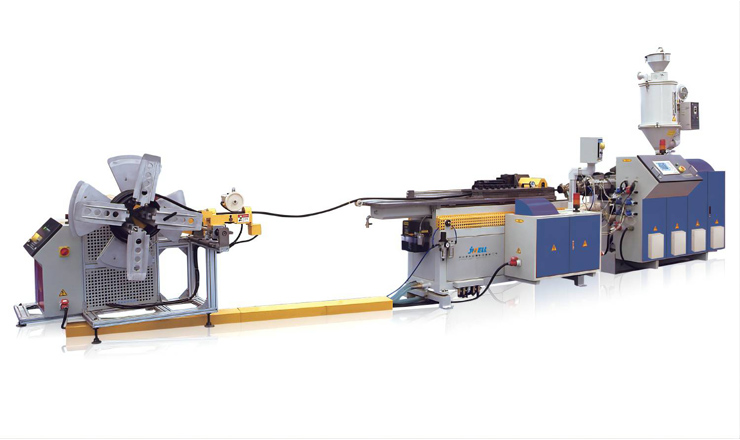

Corrugated Pipe Machine

HDPE/PP/PVC single wall corrugated and double-wall corrugated pipe extrusion line. Full automatic control, Jwell as corrugated pipe machine manufacturershas many patents. Single wall corrugated and double wall corrugated pipe machinerunning stable, high capacity.

HDPE/PP material use high efficient single screw extruder, and PVC material use conical twin screw extruder machine or parrallel twin screw extruder. Horizontal type corrugator adopt advanced shuttle-type structure, closed water cooling system, on-line belling. Whole line is controlled by PLC computer.

Descripetion about corrugated pipe machine

|

Item |

Specification |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

Single/double corrugated Φ8-Φ1500mm |

|

Certification |

CE ISO |

|

Minimum order quantity |

1 SET |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

70days |

|

Payment terms |

Specifications of corrugated pipe machine

1, HDPE/PP/PVC Horizontal Type Double Wall Corrugated Pipe Extrusion Line

|

Line Type |

Diameter(mm) |

Output(kg/h) |

Max Speed(m/min) |

Power(kw) |

|

JWSBW-160 |

Ø90~Ø160 |

200-300 |

6 |

135 |

|

JWPEG-250 |

Ø110~Ø250 |

250-350 |

5 |

280 |

|

JWPEG-500 |

Ø200~Ø400 |

250-500 |

3 |

550 |

|

JWPEG-800 |

Ø500~Ø800 |

1000-1100 |

3 |

680 |

|

JWPEG-1200 |

Ø800~Ø1200 |

1000-1200 |

1 |

800 |

|

JWPEG-1500 |

Ø1200~Ø1500 |

1200-1500 |

1100 |

2, PA/PE/PP/PVC single wall, double-wall corrugated pipe extrusion line

Mini single wall high speed corrugated pipe forming machine can produce two diameters or three diameters single wall corrugated pipe machinewith the same mould blocks, which reduce the cost of the mould blocks and the changing time, also increase the efficiency.

|

Line Type |

Diameter(mm) |

Extruder |

Max Speed(m/min) |

Power(kw) |

|

JWDPG-25 |

Ø8~Ø20 |

JWS45/30 |

15 |

50 |

|

JWDPG-50 |

Ø12~Ø50 |

JWS65/33 |

15 |

70 |

|

JWDPG-63 |

Ø12~Ø63 |

JWS65/33 |

10 |

70 |

|

JWDSB-150 |

Ø90~Ø150 |

JWS75/33 |

5 |

Corrugated pipe machine of Application

- corrugated pipe production linehave anti-high temperature, anti-wear, and high strength. Applied to electrical threading tube, automotive threading tube, sheath tube, machine tool product, packaging food machinery, electric locomotive, engineering installation, lamp, automation instrumentation, etc., market demand is larger

- Corrugated Pipe Extrusion Linefor Ventilation System corrugated pipe for air ventilation system is produced by two different PE material. Double wall corrugated pipe, and designed by hollow structure. It is easy to install in the ceiling and roofing. Also, this corrugated pipe has good performance to bear the cement. The pipe adopt special inner layer, smoothly, easy to clear, less resistance, sound-proof, insulation

FAQ about Corrugated Pipe Machine

1.What is the difference between the double wall bellows and a single wall bellows?+

The first is a single wall bellows: the inner surface of the single-walled bellows, the outer surface is corrugated, and its bendability, the flexibility is excellent, but the fluid resistance is large, and the inner surface screw groove is used to produce suspended deposition . Therefore, the single-walled bellows are more thin, and the strength requirement is not high and needs to be bent and the small diameter tube such as threading tube, the water pipe, exhaust pipe, etc.

Double wall corrugated inner tube: a new pipe with an annular structure outer wall and a smooth inner wall, mainly used in large water supply, water supply, drainage, sewage, exhaust, subway ventilation, mine ventilation, water, subway, mine ventilation, etc. Farmland irrigation, etc. Double wall bellows inner wall color usually has blue and black, and the inner wall of some brands will use yellow

2.What is the difference between the HDPE double-deck twisted pipe and HDPE double wall bellows+

3.Double-wall corrugated pipe generally have several levels?+

Corrugated pipe machine Performance and Advantages

Our large-diameter single wall and double wall corrugated pipe production line

Full automatic control, running stable, high capacity. HDPE/PP material use high efficient single screw extruder, and PVC material use conical twin screw extruder or parrallel twin screw extruder. Horizontal type corrugator adopt advanced shuttle-type structure, closed water cooling system, on-line belling. Whole line is controlled by PLC computer.

Mini single wall high speed corrugated pipe forming machine can produce two diameters or three diameters single wall corrugated pipe with the same mould blocks, which reduce the cost of the mould blocks, corrugated pipe machine priceand corrugated pipe extrusion line priceand the changing time, also increase the efficiency

New Corrugated Pipe Extrusion Line for Ventilation System high precision for front-back adjustment, according to air ventilation pipe, specially design for the mould. New vertical type water cooling corrugator, precisely location of mould block, easy to change the mould

JWELL Extrusion Machinery Co. Ltdis a high-tech manufacturer specializing in the research and development of yarn spinning machines, we provide polyester yarn making machine, jwell extruder china, plastic profile extrusion, pp hollow sheet extrusion line. Contact us to know more.

Send product request

Other supplier products

| PS Sheet Extrusion Line | The PS sheet production line of JWELLmachineryis divided into: GPPS plate production line: ordinary GPPS plate is mainly used for advertisin... | |

| Corrugated Pipe Machine | HDPE/PP/PVC single wall corrugated and double-wall corrugated pipe extrusion line. Full automatic control, Jwell as corrugated pipe machine manufac... | |

| PVC Twin Screw Extruder | PVC is a non-crystalline polymer of polyvinyl chloride. Its glass transition temperature is 105℃-75℃ depending on the molecular weight. It has flam... | |

| Spandex Machine | Spandex is the earliest developed and most widely used variety among elastic fibers and the most mature production technology. Normally two ways... | |

| Polyester Spinning Machine | Special designed Screw/Barrel, Suitable for Recycling Materials. Double Stage CPF with Boost Pump, Make Sure the Melt pressure in average & Fi... |