ADSS Fiber Optic Cable

Fiber Optic ADSS Cable is known as an all-dielectric self-supporting optical cable. Self-supporting ensures that the ADSS outdoor fiber cablehas sufficient mechanical strength. The ADSS fiber cable applies all-dielectric material to withstand the impact of strong electricity in a high voltage and strong current environment. As one of the most professional ADSS cable suppliers and manufacturers, TUOLIMA can customize the self-supporting fiber optic cable ADSS according to your requirements. If you need any technical support, we will also recommend the most suitable and cost-effective customized ADSS OFC cable for you according to the different application environments, laying methods, and customer requirements. Our all-dielectric self-supporting cables can be applied in many areas, for example, the aerial industry. You can check ADSS fiber specsbelow. If you have any questions, please feel free to contact us.

Specification of ADSS Fiber Optic Cable

|

Mechanical characteristic and test method |

||

|

Tensile strength |

conform to IEEEC standard P |

|

|

Crush |

conform to IEC 794-1-E3 |

|

|

Impact |

conform to IEC 794-1-E4 |

|

|

Repeated bending |

conform to IEC 794-1-E6 |

|

|

Torsion |

conform to IEC 794-1-E7 |

|

|

Flexing |

conform to IEC 794-1-E8 |

|

|

Cable bend |

conform to IEC 794-1-E11 |

|

|

Water penetration |

conform to IEC 794-1-F5B |

|

|

Color coding |

conform to EIA/TIA 598 |

|

|

Temperature requirement |

operation: Installation |

- 40 C~ +60 C - 10 C ~ +60 C |

|

storage/transportation |

- 40 C ~ +60 C |

|

|

Temperature cycling test |

conform to IEC 794-1-F1 |

|

|

Bending Radius |

unloaded |

15 times of outer diameter |

|

loaded |

25 times of outer diameter |

|

Characteristics of ADSS Fiber Optic Cable

|

Fiber Material |

G652D |

|

Mode field diameter (1310nm): |

|

|

Mode field diameter (1550nm): |

|

|

Cladding diameter: |

125um±1.0um |

|

Cut off wavelength of cabled fiber (ℷcc): |

≤1260nm |

|

Attenuation at 1310nm: |

≤0.36dB/km |

|

Attenuation at 1550nm: |

≤0.22dB/km |

|

Bending loss at 1550nm (100 turns, 30mm radius): |

≤0.05dB |

|

Dispersion in the range 1288 to 1339nm: |

≤3.5ps/(nm•km) |

|

Dispersion at 1550nm: |

≤18ps/(nm•km) |

|

Dispersion slope at zero dispersion wavelength: |

≤0.092ps/(nm2•km) |

Details of ADSS Fiber Optic Cable

|

SN |

Item |

Unit |

Value |

|

1 |

count |

12~288 |

|

|

2 |

Number of fibers per tube(max) |

count |

4 |

|

3 |

Number of elements |

count |

6 |

|

4 |

Cable diameter |

mm |

|

|

5 |

Cable weight |

kg/km |

121 |

|

6 |

Max allowed operating tension |

N |

5000 |

|

7 |

Short term crush |

N/100mm |

2200 |

|

8 |

Max span with 1.0% installation sag |

m |

100 |

Drawing of ADSS Fiber Optic Cable

Advantages of ADSS Fiber Optic Cable

Uninterruptible power supply erection

Adopt PE/AT sheath, excellent resistance to erosion

Small cable diameter and lightweight help reduce the impact of ice, wind, and load on towers

Large span, maximum span ≥ 1000 meters

Great tensile strength and high/low temperature resistance

Service life is expected over 30 years

Packing and Comments of ADSS Fiber Optic Cable

Packing material: Non-returnable wooden drum.

Both ends of the outdoor optical cable are securely fastened to the drum and sealed with a shrinkable cap to prevent ingress of moisture.

Cable printing: The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

Drum marking: Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with the following:

ADSS Fiber Optic Cable Installation

Basically, the installation of ADSS optic cable is divided into two steps:

Step 1: Lay, arrange, and tighten the dielectric fiber optic cable and then install cable fittings and bridge molding.

Step 2: Fiber optic connection and characteristic test of the optic fiber.

The tips of ADSS fiber optic cable installation:

The straight-line distance from the tower to the cable laying equipment shall be greater than 4 times the height of the pulley suspension point to reduce the side pressure on the optic cable. Excessive tension shall not be used to pull the optic cable during cable laying, and the traction force shall not be greater than half of the initial tension borne by the optic cable. The traction speed of the optic cable is generally not greater than 20m/min.

Send product request

Other supplier products

| Fiber Optic Splice Closure | Fosc fiber optic splice closureprovides space and protection for fiber joint closure optic splicing and joint. The fiber splice closure can be moun... | |

| TFX-05 8 Core Fiber Optic Distribution Box | Model TFX-05 is a box that splits an optical cable into a single optical fiber. It is installed on the wall for user termination. Its function is ... | |

| Fish Fiber Optic Drop Cable Clamp | FISH fiber optic drop cable clamp is the tension clamp for FTTH clamp. Fish clamp FTTH can be used in anchoring, turning, suspension fiber optic... | |

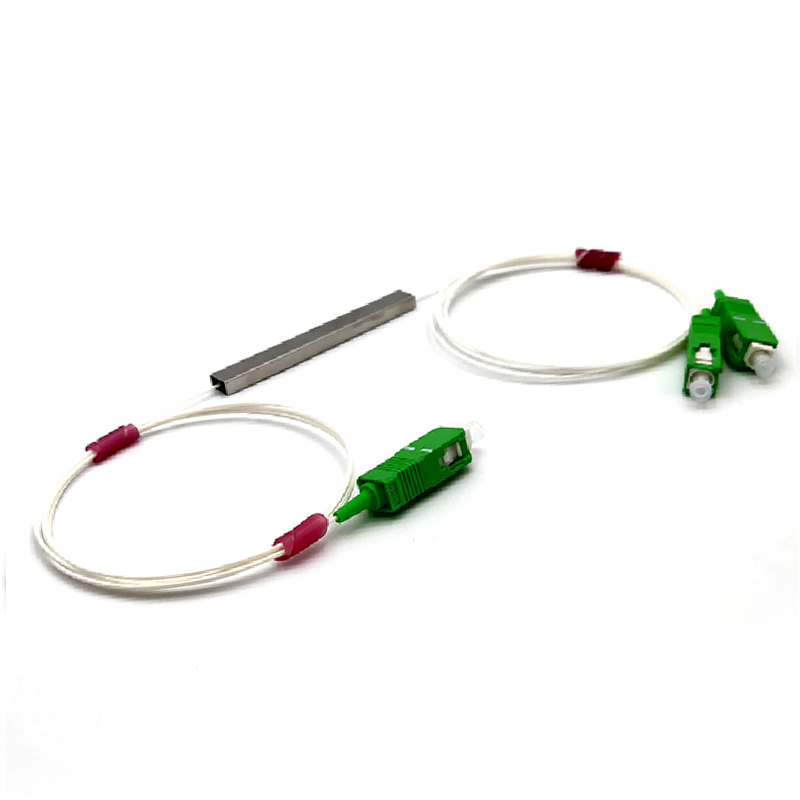

| 1*2 Mini Fiber Optic Splitter | Optical splitter is a part of passive components (also called optical passive components) in the process of optical transmission. Like coaxial cabl... | |

| TFX-04 8 Core Fiber Optic Distribution Box | TFX-04 aging splitter distribution boxis a 8 core fiber optic distribution box. The body of this optical distribution box is made of 100% ABS or... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |