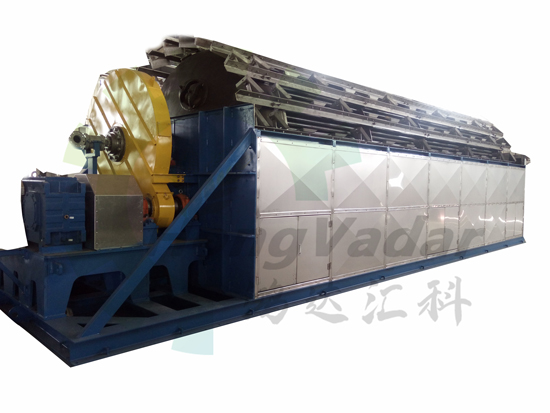

Crystallizer

Types of Horizontal Crystallizer

HVD-HCR-V horizontal agitated batch vacuum crystallizer is a piece of cooling crystallisation equipment. The source medium of crystallization is operated under atmospheric pressure. The crystallization temperature is determined by the process and the crystallization process is discontinuous. Its crystallizer machine control has outstanding characteristics are simple structure, energy-saving, and comfortable operation.

The meaning of crystallizationis a horizontal closed cylinder structure, with packing sealing device and reduction gear installed on both end covers. The tank wall has a cooling water interlayer. The hollow shaft is arranged in the center of the tank to fix the cooling coil and agitating spiral belt. Both ends of the shaft heads on crystallizer machine have the function of cooling water circulation.

Application of Horizontal equipment used for crystallization

lCrystallization of liquid glucose.

lCrystallization of glutamic acid, xylose, and xylitol.

lCrystallization of tartaric acid and malic acid.

lCrystallization of salts in the chemical industry.

lCrystallization of sodium gluconate, calcium carbonate.

Features of Horizontal Crystallizer Machine

lCustomized design of crystallization machine to meet the needs of various customers.

lThe transmission device has a compact structure, stable operation, high efficiency, and low noise.

lReliable mechanical seal, shortstop time.

lThe small gap between the spiral belt and the barrel body, uniform stirring, not blocked.

lCrystallizer machine has advanced circulating water cooling system with good cooling effect and high crystallization effect.

lStainless steel inner cylinder, corrosion resistance, long service life.

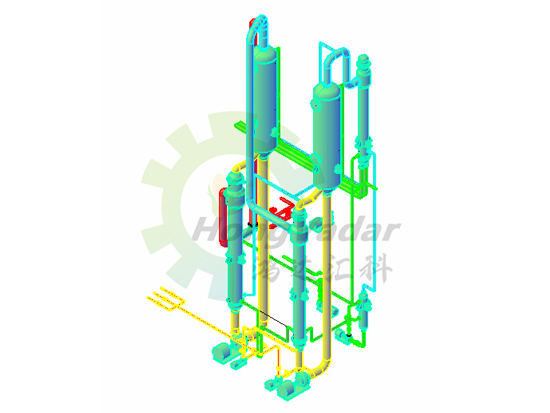

Cooling Type Vertical Continuous Crystallizer Machine

HVD-VCR-V vertical continuous crystallizer machine is used to crystallize solids from the supersaturated solution by liquid crystallization. The solution is entered through the feed pipe at the top of the crystallizer. Through the cooling module in vertical and the cooling module in series to form a pre-designed temp. the gradient to cool the material. After the crystallized material reaches the bottom of the crystallizer machine, it reaches a certain temp. and particle size, and then it is discharged through the outlet with an insulation jacket at the bottom of the equipment into the next process for processing.

The seed needed for the crystallization process is supplied from the seed tank.

Application of Cooling Type Vertical Continuous Crystallizer Machine

lCrystallization of liquid glucose.

lCrystallization of fructose, mannitol, and maltitol.

lCrystallization of glutamic acid, xylose, and xylitol.

lCrystallization of tartaric acid and malic acid.

lCrystallization of salts in the chemical industry.

lCrystallization of sodium gluconate, calcium carbonate.

Features of Cooling Type Vertical Continuous Crystallizer Machine

lContinuous and large-scale equipment for crystallisation.

lAutomatic control to ensure stable product quality.

lThis type of crystallizer machine used for crystallisation can save floor space.

lSimple and convenient operation of equipment for crystallisation.

Crystallizer Technical Parameter

Horizontal Crystallizer Technical Parameters

|

Model |

HVD-HCR-V25 |

HVD-HCR-V30 |

HVD-HCR-V36 |

HVD-HCR-V40 |

HVD-HCR-V45 |

|

Volume (m3) |

25 |

30 |

36 |

40 |

45 |

|

Working pres. (Mpa) |

≤0.16 |

||||

|

Feed DS % |

70%~75% |

||||

|

Power (kw) |

3 |

4 |

|||

|

Rotary speed (r/min) |

|||||

|

Overall dimension (mm) |

5880×2980×3545 |

6680×2980×3545 |

7165×3250×3833 |

6305×3833×4045 |

6805×3600×4045 |

|

Weight (kg) |

13500 |

15200 |

18232 |

171000 |

18420 |

Cooling Type Vertical Continuous Crystallizer Technical Parameters

|

Model |

HVD-VCR-V110 |

HVD-VCR-V178 |

|

Volume (m3) |

128 |

178 |

|

Material loading volume (m3) |

110 |

160 |

|

Effective cooling area (m2) |

250 |

380 |

|

Material |

SS304 |

SS304 |

|

Cooling modules qty. |

11 (10 groups coil + head jacket) |

12 (11 groups coil + head jacket) |

|

Cooling control circuit |

5+1 (jacket) |

5+1 (jacket) |

|

Reducer power (kW) |

||

|

Power of hydraulic station (kW) |

15 |

22 |

|

Total height around (m) |

21 |

|

|

Barrel body (mm) |

Φ3300×8 |

Φ3800×8 |

Beijing Hongvadar Engineering Technology Co. Isa professional tomato processing factory, we provide crystallization equipment ppt, surface cooled crystallizer, surface crystallizationand etc. Want to know equipment needed for crystallisationand different types of crystallization, contact us.

Send product request

Other supplier products

| Liquefaction System | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... | |

| Bundle Dryer | Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant. Bundle Dryer HVD-BD-P... | |

| Arc Screen | Gravity screen HVD-AS-G series gravity arc screen is a new type of efficient static screening equipment. The screen surface is made of stainless s... | |

| Continuous Evaporative Crystallization System | HVD-CC-T series continuous crystallization equipmentsystem is designed and developed by our factory with patent applied. Core Of Evaporative Cry... | |

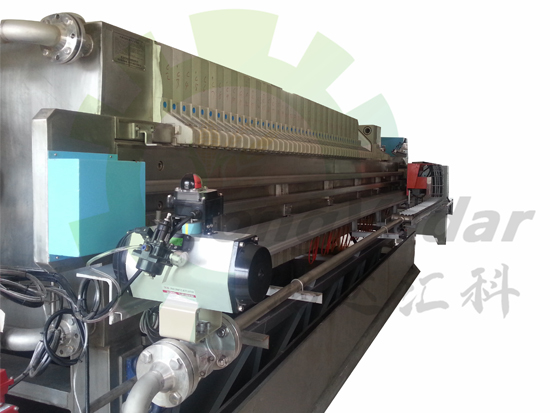

| Filter Press | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... |

Same products

| FMS888-1S Stainless Steel Industrial Box Change Locks | Seller: Ningbo Oubao Technology Co., Ltd. | Material: stainless steel base, handle, cover plate, rotating shaft, steel bolt Surface treatme... | |

| Wear-Resistant Breathable Artificial Synthetic Leather For Interior Decoration | Seller: Fu\\\'an Synthetic Materials Co.,Ltd. | This Wear-Resistant Breathable Artificial Synthetic Leather for Interior Decoration is made from ... | |

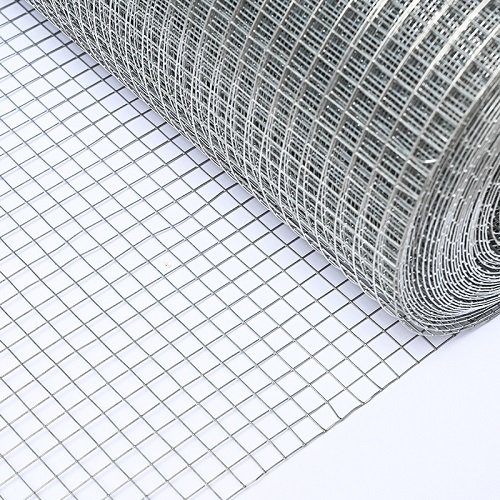

| Welded Wire Mesh Net | Seller: Jiaohao Wire Mesh Products Co., Ltd. | Constructed by fusing metal wires at their intersection points, welded wire mesh panels are mad... | |

| Steel Grating | Seller: Jiaohao Wire Mesh Products Co., Ltd. | Made from carbon steel, stainless steel or hot-dip galvanized steel with a galvanized surface t... | |

| Chain Link Fence | Seller: Jiaohao Wire Mesh Products Co., Ltd. | Chain link fence also known as cyclone fence, it is an elastic woven net. Thiswire mesh product... |