Biomass Pellet Mill with ABiomass Pellet Mill with Advanced Technology for Saledvanced Technology for Sale

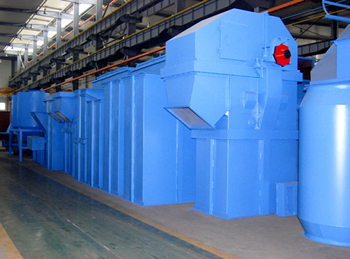

With the advanced technology and development of economy, biomass pellet mill with advanced technology for sale for producing biomass pellets turns out to be a success. The whole process of making biomass pellets consists of a series of equipments, including hammer mill, feed mixer, pellet mill, cooling machine and packing machine. When pelletizing, you have to make sure all the procedures go smoothly.

.jpg)

Materials like coarse cereal grains, corn, soy bean need to be cut into small size by a hammer mill in order to be mixed in the next step. It is known that animals feed need to be modulated and added to minerals additives to ensure animals can grow healthily and quickly, so feed mixer is an essential machine to help achieve this purpose. Pellet machine is the most crucial equipment during the pelletizing process. It is through this machine that raw materials are finally turned into various sizes of feed pellets. After being extruded from the pellet machine, feed pellets are with a high temperature and moisture content. At this moment, a cooler is needed to cool and dry them to a proper temperature and moisture content to guarantee high quality pellets. The last step is to pack them into bags for transportation or storage.

As biomass pellet mill with advanced technology for sale is continuously popular in large industries and small business, especially in family, a good knowledge of how to correctly operate the whole process to get high quality pellets is essential for all parties.

To make sure the pellets processed with high quality, users have to guarantee that the ring die pellet machine or flat die pellet machine operates smoothly. Before pelletizing, users should be familiar with every procedure during the process.

1. before starting the pellet machine, all parts should be checked whether they are fastened. Thirdly, the screws on both sides of the pressure roller should be loosed before working.

2. the storage moisture content of grain is about13%. Therefore during the mixing process of raw materials, certain amount of water should be added to meet the pelletizing requirements.

3. when processing feed pellets, feed formula should be well controlled. Users would better not add grease or molasses. To add ingredients like that, they can add atomized greasy or molasses. Also the amount can not exceed 3%.

5. the molds of pellet machine have to be grinded repeatedly for the first time. That’s to say, molds should be lubricated. This process is an important step to ensure that pellet machine can produce pellets normally. For making feed pellets, materials obtained right after the grinding process can not be used to feed animals.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Primary Stone Crusher Jaw Crusher Price | Jaw crusher is one of the most important machine in mining machinery industry. Jaw crusher is so popular just because its superior performance and ... | |

| Reliable Performance Bucket Elevator for Sale | The reliable performance bucket elevator for sale is suitable for vertical transport of products such as powder, granular and small lump materials.... | |

| Corn Stover Pellet Machine for Hot Sale/Corn Stover Pellet Mill | Biomass energy resource is a kind of harmless energy which is quite abundant on our earth. Every year, our earth generates 173 billion tons of mate... | |

| Factory Price Ring Die Pellet Machine with CE | Ring die pellet machine like football development history, is by a Chinese invention, but more and more depression, and Europe introduced our ring ... | |

| Latest Developed Dry Powder Briquette Machine for Sale | Latest developed dry powder briquette machine for sale can make briquettes from a wide range of powdery materials, including carbamide, pigment, ca... |