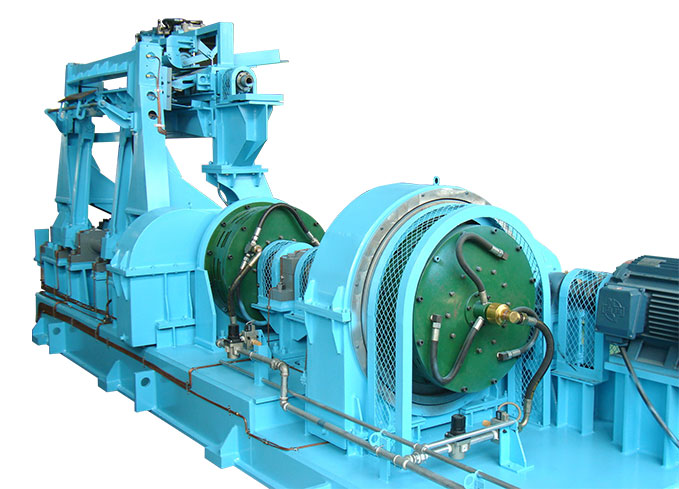

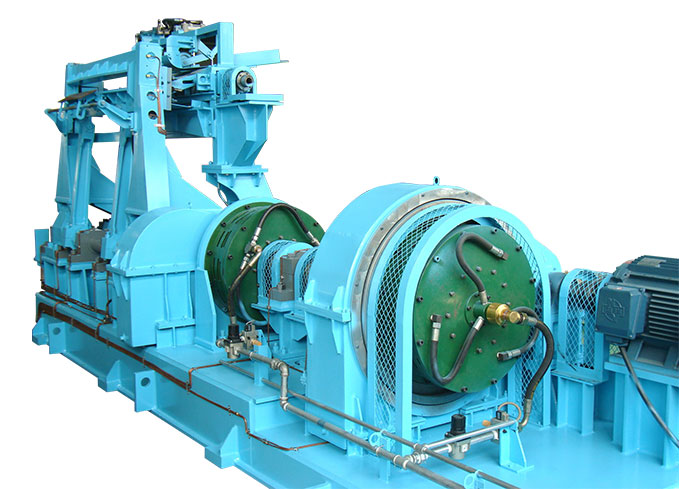

Tension Leveler for Galvanizing Line

Galvanizing line tension levelleris a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. Combining the characteristics of continuous tension metal straightener and roller straightener, the strip is straightened by plastic extension under the joint action of the tension roller and the bending roller. At the same time, in order to ensure the strip shape and surface quality, the tension leveler machine in tension leveling linescan be equipped with wet production mode, to achieve "wet type leveler" production.

Application Scope of Tension Leveler for Galvanizing Line

Application Scope Of Galvanizing Line Tension Leveler (Dry Type)

|

Material |

Strip thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Galvanized sheet carbon steel |

700-1800mm |

≤800MPa |

≤300m/min |

Application Scope Of Galvanizing Line Tension Leveler (Wet Type)

|

Material |

Strip thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Galvanized sheet (Automobile, home appliance sheet) |

500-2800mm |

≤600MPa |

≤500m/min |

Structure Advantage of Tension Leveler for Galvanizing Line

Structure Advantage Of Galvanizing Line Tension Leveler (Dry Type)

The frame of the tension levelingsteel is an assembly part, and each part is annealed separately to eliminate stress and ensure the frame is not deformed after long-term use. Meanwhile, it also provides convenience for later maintenance.

The roll-changing device is safe and convenient. It is driven by hydraulic pressure. One or all of the roller cassettes can be replaced at one time

The top roller system can be opened quickly to prevent the roller from being damaged. The bottom roller system is used for improving the flatness by adjusting the insertion amount of the lifter. The ball cage coupling is used to connect the driving motor, lifter and detection encoder to facilitate flexible adjustment and maintenance.

Configuring with two sets bending units and two sets leveling units can effectively improve the plate shap, C bending and L bending, according to the incoming material condition and process requirements, the two sets of bending units can also be used for one use and one standby.

Structure Advantage Of Galvanizing Line Tension Leveler (wet Type)

Configuring with two sets bending units and two sets of tension leveller can effectively improve the plate shape, C bending and L bending, according to the incoming material condition and process requirements, the two sets of bending units can also be used for one use and one standby.

The frame is an assembly part, and each part is annealed separately to eliminate stress and ensure the frame is not deformed after long-term use. At the same time, it also provides convenience for later maintenance.

The roll-changing device is safe and convenient. It is driven by hydraulic pressure. One or all of the roller cassettes can be replaced at one time

The top roller system can be opened quickly to prevent the roller from being damaged. The bottom roller system is used for improving the flatness by adjusting the insertion amount of the lifter. The ball cage coupling is used to connect the driving motor, lifter and the detection encoder to facilitate the flexible adjustment and maintenance.

The roller leveling machinecan be completely out of contact with the strip when the tension leveler is not put into use to prevent scratches.

The top roller system and the inner wall of the frame have taken effective medium anti-rust measures, which can effectively prevent rust water from dripping on the surface of the strip and affecting the quality of the strip.

Spray device is equipped to clean the strip surface and roller surface to ensure the surface quality of the strip.

The main body of the tension leveler machine has taken effective waterproof, anti-rust measures, good sprinkler and backwater system, which can ensure long-term reliable and stable operation of equipment.

What's The Function of Tension Leveler In Galvanizing Line

The tension leveler machine is usually installed after skin pass mill in the continuous galvanizing unit. After the annealing galvanizing and skin pass process, the strip defect can be removed by the tension leveler machine to obtain good product quality.

Specifically:

We can also offer kinds of sheet metal coil linefor sale, if you have needs, please contact us.

By start researching and developing ball cage coupling joints, BOYA Precision Industrial Equipments Co., Ltd is engaged in producing core components for important equipment in the metallurgical industry and supplying all kinds of precision equipment to various process lines, it's a unique metallurgical machinerymanufacturer and the most valuable solution provider.

No the price of scrap balleris reasonable, if you have needs, please contact us.

Send product request

Other supplier products

| Rotary Shear for Annealing and Galvanizing Line | In order to ensure that the tearing surface of the strip is smooth, it is necessary to ensure that the upper and lower knife planes are relatively ... | |

| Tension Leveler for Galvanizing Line | Galvanizing line tension levelleris a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. ... | |

| Work Roll | BOYA produces slender rolls such as smooth roll (can be chromed), spiral roll (can be chromed), and concave roll. There are more than 10 kinds of r... | |

| Scrap Baller | The scrap balleris an excellent choice for us to dispose of waste materials. It rolls the cut edges into a ball and recycles them, and sorts the cu... | |

| Rotary Shear for Annealing and Galvanizing Line | In order to ensure that the tearing surface of the strip is smooth, it is necessary to ensure that the upper and lower knife planes are relatively ... |

Same products

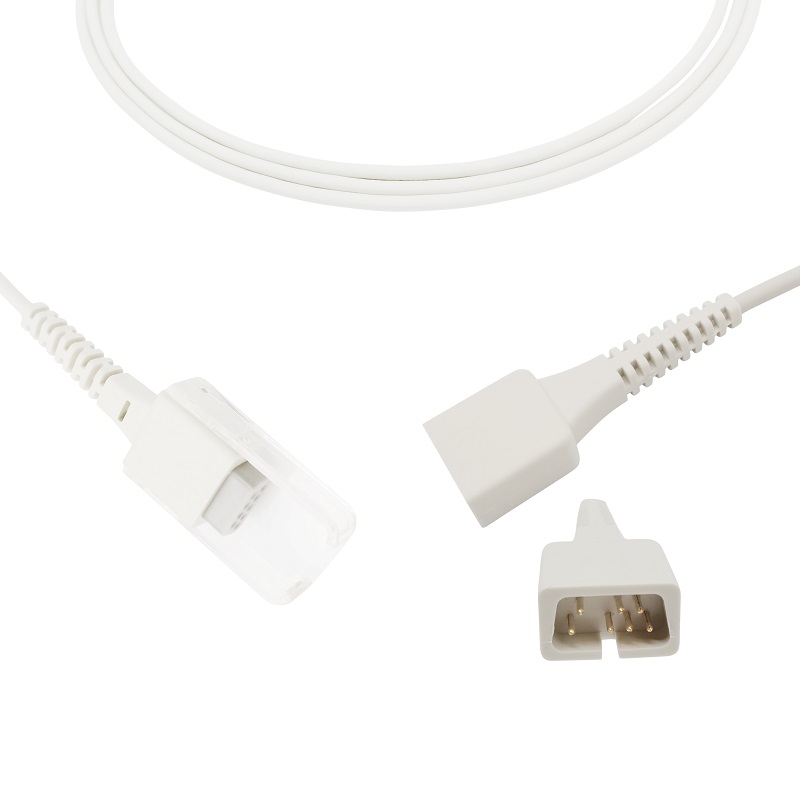

| A1418-C01 Covidien > Nellcor Compatible SpO2 Adapter Cable with 240cm Cable 7pin-DB9 | Seller: APK Technology Co., Ltd. | Parameter of A1418-C01 SpO2 Adapter Cables APK Part Number A1418-C01 OEM P... | |

| SpO2 Adult Ear Clip | Seller: APK Technology Co., Ltd. | SpO2 Adult Ear Clip Pulse Oximeter Parameters of 1032047 Spare Parts APK Part Number 1032047 OEM... | |

| SpO2 Adult Rubber Ear Clip Holder | Seller: APK Technology Co., Ltd. | Parameters of 1032046 Spare Parts APK Part Number 1032046 OEM Part Number N/A OEM Manufacturer N... | |

| A1411-SN07 Nihon Kohden Compatible Neonatal SpO2 Sensor with 90cm Cable DB9(9pin) | Seller: APK Technology Co., Ltd. | Parameters of A1411-SN07 SpO2 Sensor APK Part Number A1411-SN07 OEM Part Number N/A OEM Manufactu... | |

| A1411-SI01 Nihon Kohden Compatible Infant SpO2 Sensor with 90cm Cable DB9(9pin) | Seller: APK Technology Co., Ltd. | Parameters of A1411-SI01 Infant SpO2 Sensor APK Part Number A1411-SI01 OEM Part Number N/A OEM Ma... |