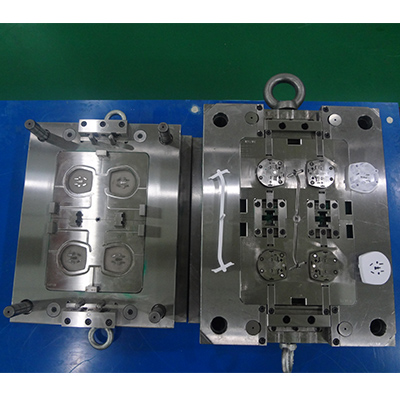

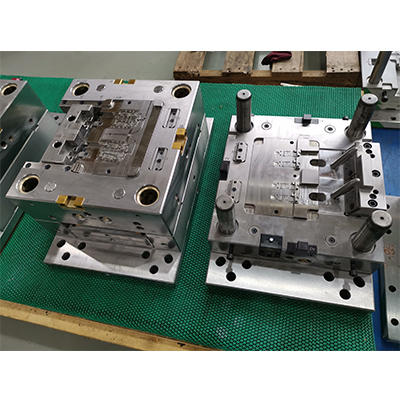

Industrial Molding Parts

Industrial hanking mould parts are referred to the plastic parts of industrial products, HanKing Mould Enginering Ltd.preferred to think of it as non-consumer products.

Nowadays, the demand for consumer products is oversupplied, and the demand for industrial precision molded products incis increasing. This is because many parts of the equipment in the past were made of metal. With the development of the plastics industry, more and more industrial product parts are trying plasticization. Metal parts have higher density, greater strength, and thermal and electrical conductivity. However, plastic industrial parts have advantages in mechanical shock absorption, thermal expansion, elongation at break, and toughness. And the properties of plastics can be greatly transformed by the addition of fillers, reinforcing materials and modified materials, engineering plastics perform better in this respect. Use plastic to produce parts that are not necessary for high strength can reduce the weight of equipment, simplify the structure and save costs, this is why industrial molding parts are becoming more and more common.

Industrial injection molded parts chinarange from small plastic gears to large industrial equipment plastic enclosures. The design of the hanking moldis very complicated work, the plastic part structure, the different plastic resin, required life cycle, etc. many factors determine the mold construction.

Designersof Hankingtecmust master the properties of different plastics and mould steel, and consider the temperature change, pressure change, steel abrasion during the production process, designed qualified mould.

If the mould structure of hanking moulding is unreasonable, even the most excellent operator of hanking mould technology can not get good plastic parts. The design of hanking defects cannot be solved by the defects in the production process. Only when all the factors are considered in the design of the mould, the shenzhen hankingmould quality and stability of the mass production can be guaranteed.

Send product request

Other supplier products

| Adapter Charger Housing Mold 496-1 | Mould Name: Adapter Charger Housing Mould Part Material: PC Product Size: 58.3*57.9*8.6mm Product Description: Adapter Charger Housing UK Mould Cav... | |

| Plastic Insert Mold | With continuous developments and progresses, we have become theprofessional china plastic injection mould manufacturers, offering custom plastic in... | |

| Consumer Parts Plastic Mold | Description: Plastic Valve 3 Plate Mould Tolerance: +-0.01mm Surface: SPI A2 & VDI 3400 Part material: PPO food grade Shrinkage: 0.... | |

| Custom Injection Mold Making Services for Auto Parts | Custom Injection Mould Making Servicesfor Auto Parts Mould Type: Automotive Final Sensor Production Material: 33% glass fiber reinforced, black PA... | |

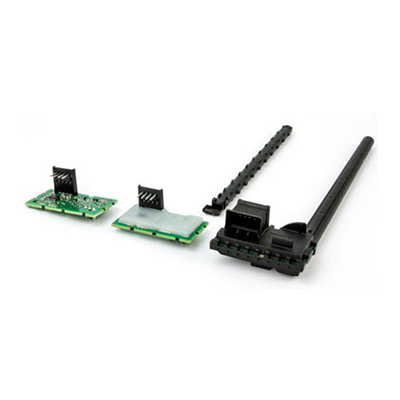

| Electronic Molding Parts | HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... |

Same products

| Enhanced Water-Cooled Paddle Wheel Aerator | Seller: Taizhou Yuansheng Aquacul Ture Machinery Co., Ltd. | The Enhanced Water-Cooled Paddle Wheel Aeratoris engineered for steady, long-term use in medium t... | |

| Honeywell BW MicroClip Series XT-XWHM-Y-CN | Seller: CW Green Tech | Honeywell BW MicroClip Series XT-XWHM-Y-CN The industrial Honeywell BW™ MicroClip Series i... | |

| High-Efficiency Sludge Dewatering Machine for Wastewater | Seller: Apoaqua | The sludge dewatering machine produced by Apoaqua follows the principles of force and water in th... | |

| Climate And Vibration Combined Test | Seller: Guangdong Yuanyao Test Equipment Co.,Ltd. | Model: YTHV-216 YTHV-343 YTHV-512 YTHV-720 YTHV-1000 Main Parameters: Temperature: 0℃/-20℃/... | |

| High Temperature Clean Drying Oven | Seller: Guangdong Yuanyao Test Equipment Co.,Ltd. | Model: YCO-072 YCO-270 YCO-480 YCO-600 YCO-720 YCO-1000 Main Parameters: Dustproof class: C... |