Pellet Cooler Price/Professional Pellet Cooler Manufacturer

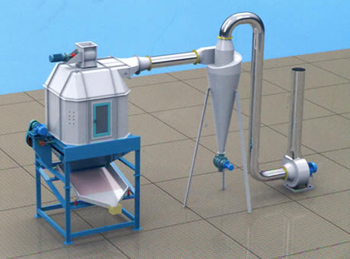

Pellet cooler price/professional pellet cooler manufacturer is used to cool the pellets after pressed by the Ring Die Pellet Mill, since the pellets are hot and contain much vapor when just get out of the pellet mill. The function of pellet cooler is to cool the pellets to room temperature. The cooler made by Henan Fote Heavy Machinery Co., Ltd. is counterflow type: the hot pellets be fed into the cooling chamber and filed evenly onto the paralleled turning plates. Also, broken pellets or powder will be screened through the sieve and collected for reproduction. Usually, if the pellet cooler is set to the ideal status, the outlet pellets can reach the temperature of just 2-5℃ higher than room temperature.

The cooling of granules is an indispensible process of pelletizing section. The temp of granules frompellet mill can be reduced from 70°C——90°C to just 3°C to 5°C higher than the ambient temperature by using reverse-flow cooler, and to the required water moisture(≤12.50℃) for the convenience of pellet transport, storage and reserve.

As of now, the pellet cooler price/professional pellet cooler manufactuer, as one of the latest coolers prevailing across the globe, avails itself of the counter flow cooling theory to refrigerate granules with high temp and moisture, namely, when vertically passing through the bed of material, the cold air will sweep through cold material. And then the increasingly warm-up air will diffuse together with hot material yet the air direction is opposite to the material flow, hence, granules will be cooled gradually and forwardly lest other coolers directly shock-chill the high-temp material and the surface of granules thereby crazes. Because the cold air goes into the cooler in all direction covering large area and in high-use, therefore, the cooling effect is outstanding. Also, thanks to its low energy consumption and convenient operation, this type of cooler precedes over even updated vertical and horizontal types. Both the upper and lower level detector mounted on the door will automatically control cooling time and discharge pellets.

The pellet cooler price/professional pellet cooler manufacturer mainly consists of air seal machine, induced draft cover, cooling box, both upper and lower material level indicators, reducer, framework and aggregate bin. The working process remains as follows: the high-temp and high moisture granules produced from the pellet mill will be piled up in the cooling box by after passing through air seal machine and material discharger in turn. Cold air through cooling box will enter into the cooler, and its heat exchange with damp and hot granules will take place after the cold air going through the bed of material. Then, granules will get cooled after the work of induced draft system. Cool-down time depends on positions of both upper and lower material level sensors, that is, when the level of material reach to the upper, material discharge will be driven by motor and vice versa. The cooled granules will be discharged out by the aggregate bin.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer | Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer Brief Introduction As a traditional drying machine, rotary drum dryer is an industrial we... | |

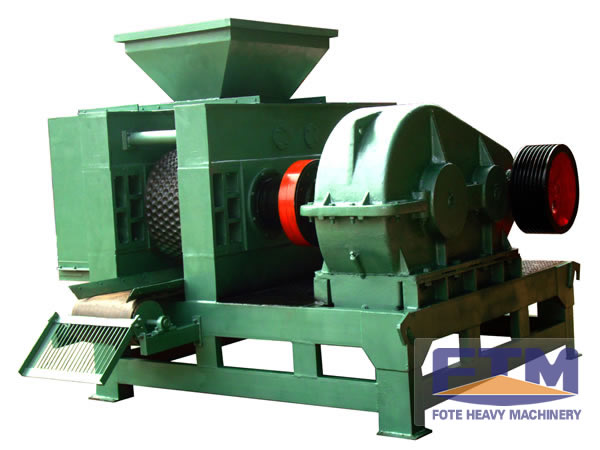

| New Type Charcoal Briquette Making Machine for Sale | With the rapid development of the economy, the world's demand for charcoal has risen over the years. The annual demand in chemical and metallurgica... | |

| Sludge Briquetting Machine Supplier/Sludge Briquette Press Maker | Sludge briquetting machine supplier/sludge briquette press maker is mainly used for briquetting non-ferrous and black metal ore powder into ball sh... | |

| Corn Stover Pellet Machine for Hot Sale/Corn Stover Pellet Mill | Biomass energy resource is a kind of harmless energy which is quite abundant on our earth. Every year, our earth generates 173 billion tons of mate... | |

| Sawdust Briquette Machine Supplier/Sawdust Pellet Machine | Sawdust briquette machine supplier/sawdust pellet machine is new type biomass renewable energy equipment. It has advantages of low production cost ... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | Seller: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

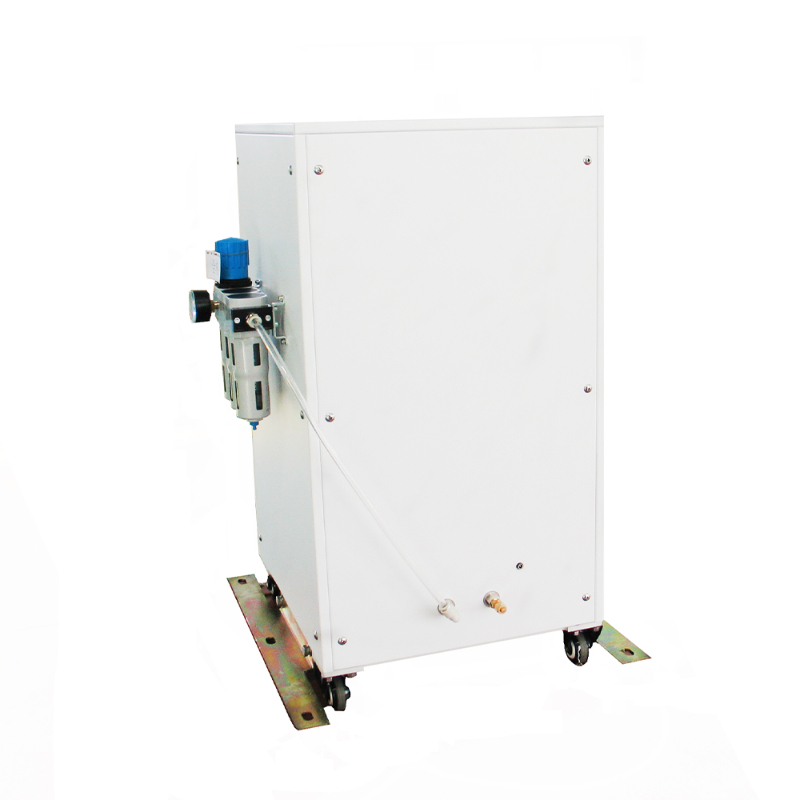

| Mini Nitrogen Generator | Seller: Shandong benyuan international trading co,.ltd. | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

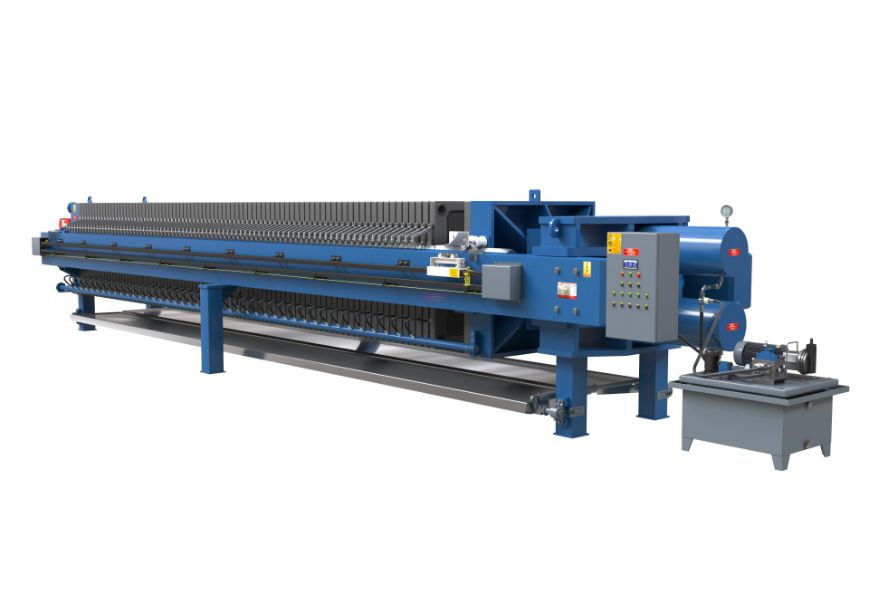

| filter press in chemical industry | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Seller: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | Seller: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |