Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer

Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer Brief Introduction

As a traditional drying machine, rotary drum dryer is an industrial welcome dryer machine employed to reduce or minimize the moisture content of sawdust or wood chips. Rotary drum dryer has wide application to various biomass materials like sawdust, wood shavings and agricultural straw. Reasonable structure, high efficiency, low energy consumption and convenient for transportation makes sawdust dryerstand out among wood material drying equipment.

Wide Application of Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer

1. For the materials that require low-temperature dry.

2. For chemical, miners, metallurgical and other industries: such as ores, slag, coal, metal powder, clay, kaolin, etc.

3. For powdery, granular material dryer: such as crystals, precipitated calcium carbonate, activated clay, phosphorus slag, etc.

4. For agriculture, feed, fertilizer industries: such as straw, grass, leaves, fish meal, corn sauce, aquatic wastes, food factory waste, etc.

The dryer is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under gravity. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

Characteristics of Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer

1. High heat transfer coefficient and thermal efficiency.

2. Strong overloading capacity resistance, large process load, low fuel consumption and low cost.

3. The product moisture can be dried less than 8% and the granularity should be less than 8mm.

4. Fully automatic control, large drying capacity from 0.5-2.5ton per hour.

5. High temperature(≤700℃) resistance ensures efficient drying.

6. The operation of the rotary drum is stable and reliable.

Working Principle of Rotary Drum Dryer for Sale/Rotary Drum Dryer Manufacturer

When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Based on the configuration, rotary dryers can be classified as co-current, counter current, direct fired and indirect fired.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Latest Excellent Airflow Dryer for Sale/Airflow Dryer Manufacturer | The latest excellent airflow dryer for sale, known as a hot airflow impulse dryer or air current dryer, is also called hot air pipe dryer with adva... | |

| Small Wood Pellet Mill/Small Capacity Wood Pellet Mill | The idea of owning a small pellet making machinery at home is a great one. It is amazing that you can process sawdust into wood pellets, even at ho... | |

| Charcoal Briquette Maker/Charcoal Powder Briquette Machine Price | As is well known to us, charcoal briquette is formed when you burn carbon-rich materials such as wood in a poor-oxygen atmosphere. This process dri... | |

| Reasons for Low Capacity of Sawdust Pellet Mill | Sawdust pellet mill is a kind of machinery which applying to process sawdust. Sawdust pellet machine can suppress materials which are not oily and ... | |

| High Production Raymond Mill/Raymond Milling Machine | Raymond mill has been used primarily for barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activ... |

Same products

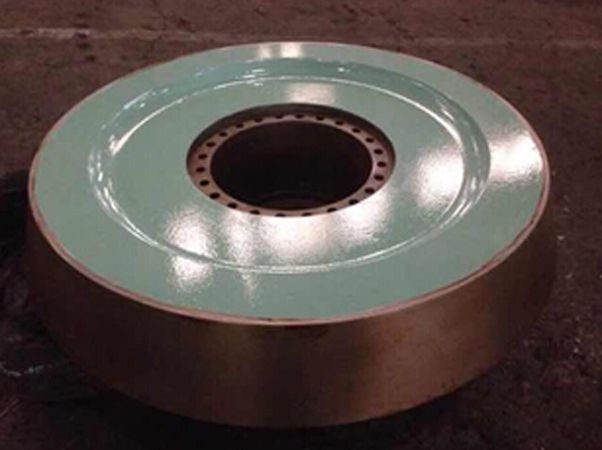

| Thrust Roller | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC is a more than 30-year manufacturer and reputed supplier of thrust roller used in rotary kiln... | |

| HBY-30 Constant Temperature Water Curing Box (horizontal) | Seller: Zhejiang Luda Machinery Instrument Co.,Ltd | This type of water curing tank is designed and manufactured according to the maintenance requirem... | |

| HBY-30 Constant Temperature Water Curing Box (vertical) | Seller: Zhejiang Luda Machinery Instrument Co.,Ltd | This type of water curing tank is designed and manufactured according to the maintenance requirem... | |

| FSY-150 Cement Fineness Negative Pressure Sieve Analyzer (ordinary) | Seller: Zhejiang Luda Machinery Instrument Co.,Ltd | This equipment is widely used in cement fineness inspection and cement production control. It can... | |

| FZ-31 Boiling Box | Seller: Zhejiang Luda Machinery Instrument Co.,Ltd | This equipment is one of the commonly used equipment in cement production, construction, scientif... |