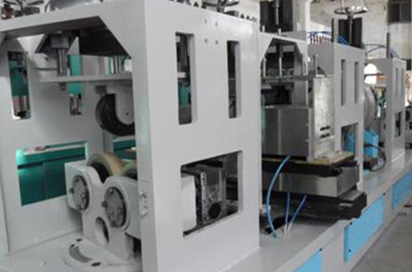

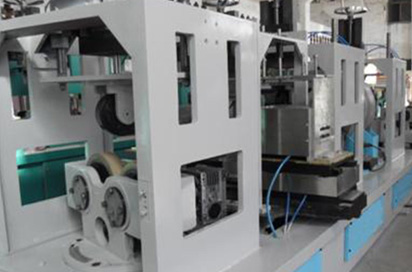

MFL-7389 Tube Magnetic Flux Leakage Detector

Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing tubing. It can ensure the quality of oil and water wells to prolong the inspection cycle, reduce the rework of operations and reduce operating costs.

As an important process in the tubing repair test line, the flaw detection can accurately and effectively detect the defects in the manufacture and use of the inner and outer wall and the pipe body of the oil pipe to ensure the repair quality of the oil pipe.

Fundamental

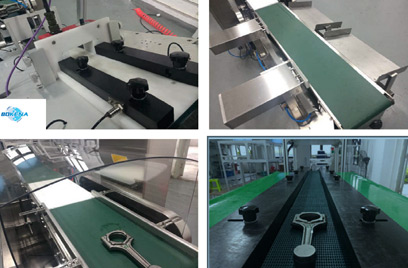

When the detected tubing is saturated and magnetized, the magnetic field lines are distorted by the magnetic lines of force at the defect blocking defect, and a part of the magnetic lines leak out of the inner surface of the tube rod to form a leakage magnetic field, and the electromagnetic detecting method for detecting the leakage magnetic field by the detecting element is detected. Magnetic flux leakage inspection.

The leakage magnetic field picked up by the probe from the defect is amplified and converted into a digital signal, and then visually reflected by the flaw detector to the display to display the defect signal from the flaw detector, and directly determine the defect type and size of the detected tube rod.

¢73 and ¢89mm tubing eccentric wear and corrosion pits are detected, automatic detection, automatic alarm, automatic identification, automatic alarm.

BKN's new mfl tube inspectionhas high sensitivity to very small defects. It can effectively detect defects such as corrosion pits, eccentric wear on the inner wall of the tubing, thinning of tubing wall, etc.

Moreover, the testing speed is fast and pollution-free, and the detection is fully automated. The computer display screen is used to display the detection curve, automatic alarm, marking (defect of steel pipe), grading of tubing (grade I, II and scrap).

Send product request

Other supplier products

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 MFL Tank Floor Scanner Unique full modular structure, from the main body of the computer mechanism the handle ... | |

| Magnetic Flux Leakage Testing Equipment | BKN is one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, ndt ultrasonic testing equipment, ... | |

| GTET-02 Cylinder Liner Eddy Current Testing Machine 1024 | We have eddy current machine for sale! GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction The rate of missed standard defect is 0%; ... | |

| GTET-02 Cylinder Liner Eddy Current Testing Machine | We have eddy current machine for sale! GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction The rate of missed standard defect is 0... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | Seller: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

| Mini Nitrogen Generator | Seller: Shandong benyuan international trading co,.ltd. | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

| filter press in chemical industry | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Seller: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | Seller: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |