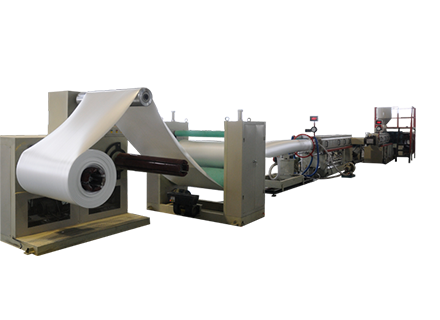

PS Foam Sheet Extrusion Line

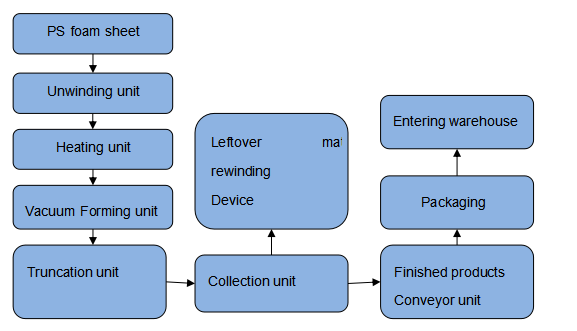

The PS foam sheet extrusion lineadopts the twin-screw series high foam sheet production process, and the produced PS foam sheet is a new type of packaging material, which not only has good heat insulation and cushioning properties but also has pearl-like Appearance color. It is mainly used in the manufacture of disposable tableware. It can be used to make various types of food containers such as lunch boxes, trays, and dishes. It can also be used in the production of advertising and packaging of industrial products. It has the characteristics of high output, stable performance, a high degree of automation and high product quality.

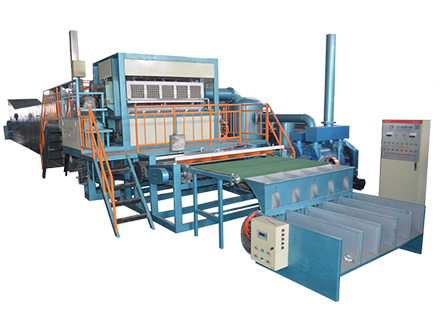

Applicationof foam sheet extrusion line

Fruit, vegetable and raw meat trays; food industry and fast food packaging; egg packaging.

Fast food boxes, bowls, trays, and other cutlery.

Medical materials; decorative materials.

Building insulation (wallpaper, filling material and ceiling).

For cold or hot polystyrene containers to hold in cooked food or ice cream.

Polystyrene can be used for printing, easy to stack, waterproof, antibacterial and good insulation.

|

Model |

HR-PSP 70/90 |

HR- PSP 105/120 |

HR- PSP 120/135 |

HR- PSP 135/150 |

HR- PSP 150/200 |

|

|

Screw Diameter |

Φ70 / 90 |

Φ105 / 120 |

Φ120 / 135 |

Φ135 / 150 |

Φ150 / 200 |

|

|

Foaming Ratio |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

|

|

Sheet Width(mm) |

640-1040 |

640-1040 |

640-1040 |

640-1200 |

1000-1350 |

|

|

Sheet Thickness(mm) |

||||||

|

Capacity (kg/h) |

50-90 |

100-180 |

180-230 |

230-320 |

400-600 |

|

|

Cutting Mode |

Single Cutting |

Double Cutting |

||||

|

Cooling Mode |

Air-cooled water cooled |

|||||

|

Rated Power(kW) |

120 |

150 |

180 |

260 |

380 |

|

|

Dimensions (mm) |

22*4.0*2.8 |

24*4.1*2.8 |

26*4.2*3 |

28*4.2*3.2 |

28*5.2*3.2 |

|

|

Weight(T) |

10 |

12 |

15 |

18 |

twenty three |

|

Send product request

Other supplier products

| Sit Stand Desk Converter | Description of Sit Stand Desk Converter: Height adjustable standing desk convertercan turn your desk into a healthy workstation in a few minutes. ... | |

| Apple Tray Production Line | In order to protect the fruit like apple, pear etc. during transportation, there designs the apple tray, which is also made by waste paper. This ki... | |

| Automatic Egg Carton Production Line | Paper egg carton/egg box is a popular pulp molded package, which is used for the boutique packaging of eggs, usually, we can find in the supermark... | |

| Four Leg Power Adjustable Standing Desk With Multiple Monitors | Description of Four Leg Power Adjustable Standing Desk With Multiple Monitors: Sitting for most of the day can wreak havoc on multiple systems, wh... | |

| Manual Egg Carton Production Line | Longkou City Hongrun Packing Machinery Co., Ltd developed thelinedepending on the needs of high-end pulp molded packaging.The egg cartons are popul... |

Same products

| Complete Trailer Axles | Seller: SHANDONG ZHENGYANG MACHINERY CO.,LTD. | The Complete Trailer Axlescome in a variety of sizes and configurations to meet your diverse need... | |

| Explosion-proof Vacuum Cleaner | Seller: Dongguan VILLO Technology Inc. | The ATEXvacuum cleaneris equipped with a turbine motor, which can work continuously for 24 hours,... | |

| Vertical Facing And Centering Machine VZ820550 | Seller: Lecn Anhui Co., Ltd | VZ820550 Product Description Both ends of the one clamping are processed at the same time, the ... | |

| machinery supplier | Seller: Zooming Manufacturing inc | Zooming Manufacturing incCNC machining 5 Axis machining Precision machining machinery supplier 5 ... | |

| YDS-30 cryo storage tank 30L cryocan liquid nitrogen container price | Seller: Henan Tianzhidao Biological Technology Co., Ltd | Tianchi KGSQ liquid nitrogen tank is a device used to store liquid nitrogen. It is made of alumin... |