Automotive Machining and CNC Auto Parts

As a precision machining company, we are devoted us in CNC prototypes, small and low volume CNC manufacturing, high volume CNC production, Brass machining, CNC turningand milling, Grinding, EDM/WEDM, die-casting products, etc. Products are widely used in Medical, Automotive, Aerospace, Car & Motorcycle, Precision Mechanical Parts, Consumer Electronics, Communication Equipment and other fields.

Automotive Parts & Products Machining

Road Ready Performance

Bespoke/OEM CNC Machining Car Parts

CNC Auto Parts Manufacturers

In recent years, automotive machining industry is developing fast and getting attention to more and more countries, and we are very optimistic about the prospects of CNCmachining car partsindustry. We have been providing automotive machining CNC car parts for many years for SHENZHEN BYD. At the same time, more and more CNCauto parts manufacturers are cooperating with us to accelerate the development of new CNCauto parts and bring them to the market faster.

Our Auto MachineServices

- Our capabilities of automotive machining

Newly designed automotive CNCcar parts are diverse and complex. LJZ is good at the flexible use of multiple technologies and skills for CNCmachining car parts. Our precision machining technology includes: CNC Swiss machining, CNCquick turn CNC machiningand milling, Multi spindle cam automatics, CNC grinding, EDM/WEDM, and so on.

- Materials used in automtotive machining

We have experience of machining more than 475 kinds of materials which includes materials for CNCmachining car parts. At LJZ automotive CNC machine shop, we are equipped with a spectrum analyzers to ensure the authenticity of raw materials. Common materials of injection moulding automotive partsthat we work with are aluminum,China stainless steel machining,copper, brass, PVC, POM, NYLON, PEEK, etc.

- Surface finishes on CNCauto parts

Many CNCauto parts will be requested for corresponding surface treatments to enhance the corrosion resistance and wear resistance so as to increase theautomotive machining service life. Common surface treatments for CNC machined auto parts include: blackening,electroplating surface finish, anodizing, laser engraving, silk screen, and so on.

Why is LJZ Used for Automotive Machining Development?

- Rapid Prototyping

Customized autorapid CNC prototypingand parts including performance parts and aftermarket parts. Without sacrificing development speed, prototyping to reduce design risks.

- Mass Customization

Customize more diversified and customized automotive functions. Through our precise Siwss machining and automotive plastic injection moldingChina process, we can quickly occupy the market.

- Tools and Fixtures

Improve the manufacturing process and create higher automation and simplified assembly of components through custom fixtures.

Common Automotive Machining Applications

- Assembly line components

- Fixtures

- Enclosure and housing

- Plastic dashboard components

- After-sales parts

- Lens and lighting components

- And more

Why LJZ for Automotive Development?

- ISO 16949 standard, PPAP, FMEA and FAI reporting are available for automotive customers basically demand.

- Provide technical consultation, pre-review of drawings, structural analysis, risk assessment, constructive design suggestions, cost analysis and other services.

- 475 kinds of materials + 30 kinds of processing technology + 21 kinds of surface treatment + customized packaging

Contact us for more details from automotive plastic injection molding companies, or simplystart with a free quote now!

Automotive Machining Parts Gallery

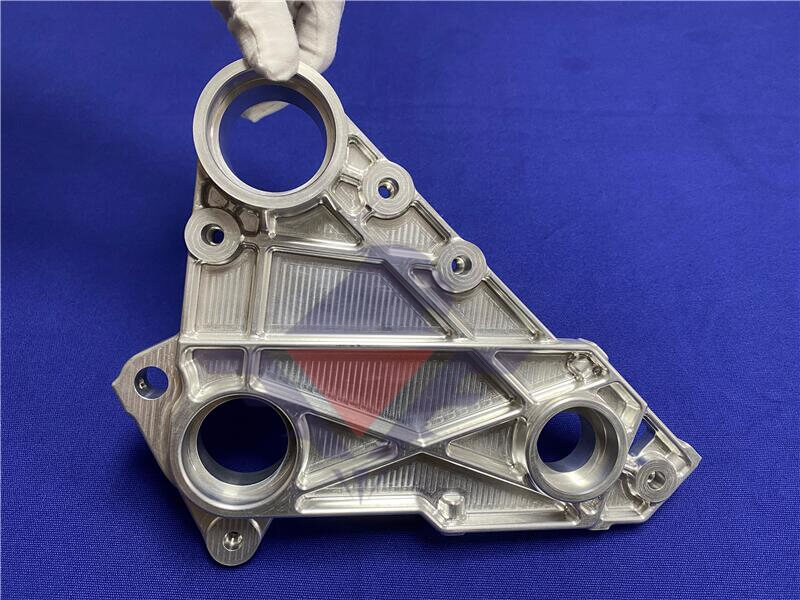

Auto Aluminum Machining Part

Automotive Machining Part

CNC Auto Brass Parts

CNC Auto Engine Part

CNC Auto Parts

CNC Auto Performance Part

Custom Auto Parts

Swiss Screws for Auto

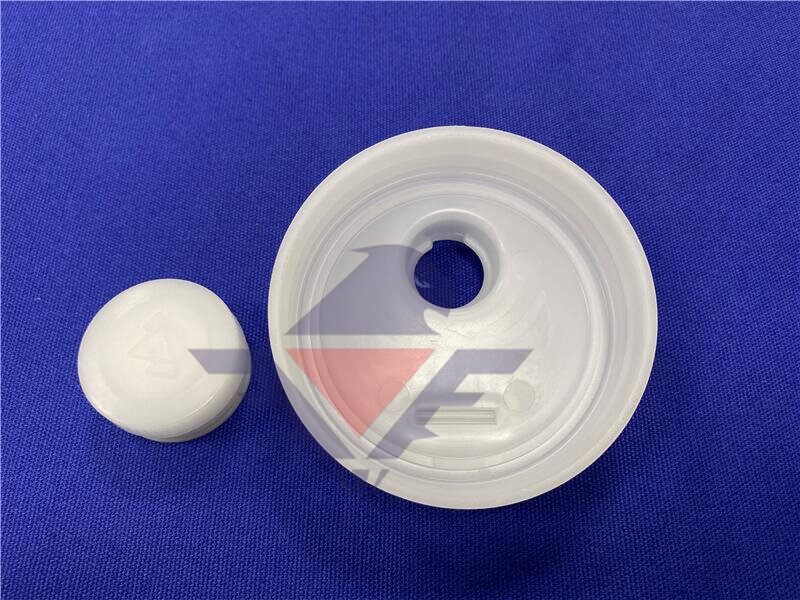

Plastic Injection Molding for Auto

Send product request

Other supplier products

| Custom Machining of Titanium Alloy | At LJZ, we are committed to providing you with superlative CNC manufacturing services with great precision. Our excellent services are precision CN... | |

| Automotive Machining and CNC Auto Parts | As a precision machining company, we are devoted us in CNC prototypes, small and low volume CNC manufacturing, high volume CNC production, Brass ma... | |

| Brass Machining | Copper or brass has excellent conductivity, ductility, corrosion resistance, wear-resistance, and other unique properties, which make brass or copp... | |

| Materials | At LJZ, we are committed to providing you with superlative CNC manufacturing services with great precision. Our excellent services are precision CN... | |

| Plastic Machining | In industrial design, in addition to commonly used metals, engineers also favor engineering-grade plastics. These plastic ptfe machined parts, tefl... |

Same products

| 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System ICHES-B is a high-voltage energy s... | |

| 24V 60Ah Lithium-ion Battery for Golf Cart | Seller: Shenzhen Changing Technology Co., Ltd | 24V 60Ah Lithium-ion Battery for Golf Cart The UT-GC2 Series 24V 60Ah Golf Cart Lithium-ion Batt... | |

| The 332.8V 10kWh (Single Phase) | Seller: Shenzhen Changing Technology Co., Ltd | The 332.8V 10kWh (Single Phase) Residential Energy Storage Systemis a high-capacity, premium-grad... | |

| 220/230/240V 5kWh - Residential Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 220/230/240V 5kWh - Residential Energy Storage System The 220/230/240V 5kWh Residential Energy S... | |

| Stationary Valve Core Grinding Bench | Seller: Metals Kingdom Industry Limited | Stationary Valve Core Grinding Bench is suitable for the valve disks of gate valves and ... |