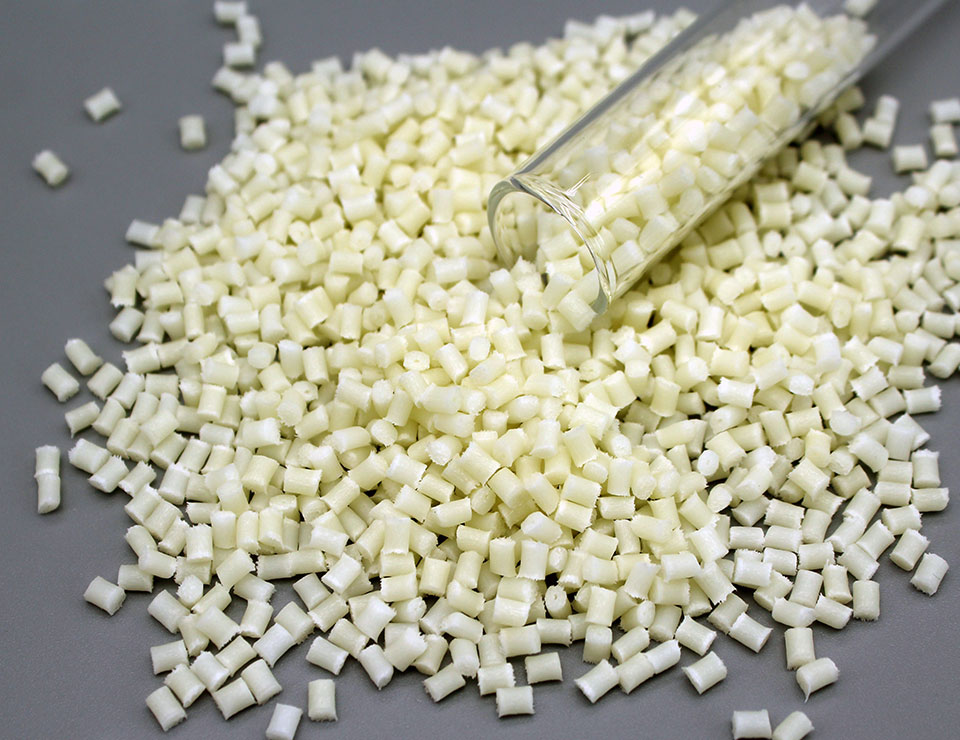

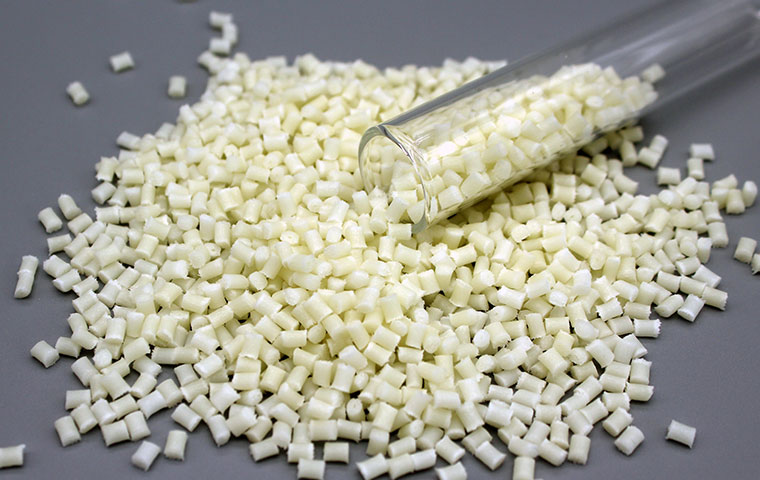

PA66 GF20 With High Tensile Strength (A2307D, A2317D) for Engineering Plastics

Elastomer toughened nylon 66 with 20% glass fiber is called PA66 GF20, it shows high oil resistance, high impact resistance, good resistance to low-temperature notch impact strength for high impact resistance parts. Anmeimodified plastic, as a big and responsible PA66 GF20manufacturer, has always been producing high-quality chemical material products. If you are interested in our PA66 GF20, you can contact us from below. We will give you a reasonable price of this products.

Typical Application of PA66 GF20 With High Tensile Strength (A2307D)

Application in the field of power tool shells is requiring high toughness, high appearance, easy forming, , high rigidity, and oil resistance but low cost. It is commonly used in PA66+20%GF HB

Processing Detail of PA66 GF20 With High Tensile Strength (A2307D)

Other Details of PA66 GF20 With High Tensile Strength (A2307D)

|

Physical Property |

|

|

Ash |

(20.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1210Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.5-0.9 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.8-1.1% I ISO294-4) |

|

Mechanical Properties |

|

|

Tensile strength (105.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/ min |

|

Notched Impact Strength (10.0 KJ/m2 I ISO179) Conditioned |

|

|

Flexural Strength (177MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (5050 MPa I ISO178) Conditioned |

2mm/min |

|

Thermal Property |

|

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(230*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

|

Injection Molding Conditions |

|

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions are just for reference, please make an adjustment based on the actual situation!

As an engineering plastic company, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Engineering Plastic & Masterbatch in Anmei | ANMEI, YOUR PROFESSIONAL PLASTIC SUPPLIER! Contact US TODAY ANMEI focuses onsupplying the 5G New energy and intelligence appliance market with eng... | |

| PA66 GF | Anmei focuses on the production of modified engineering plastics. We have polyamide pa6 6gfmodified products with propertiesof heat-resistant, rei... | |

| Masterbatch | We are here to be your reliable partners of Color Masterbatch. Color masterbatches are widely used in polyethylene(PE), polypropylene(PP), polysty... | |

| PA6 GF | Anmei-PA6 GF for Engineering Plastics As an engineered plastics company, Anmei focuses on the production of modified engineering plastics, among... | |

| PA6 GF in Anmei | As anengineered plastics company, Anmei focuses on the production of modified engineering plastics, among which high-performance nylon 6 engineerin... |

Same products

| Defoamer Powder | Seller: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |