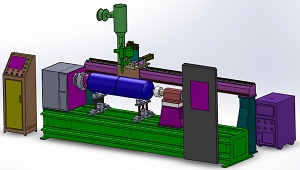

LPG Tank MIG Automatic Welding Machinery

1.Welding torch can be adjusted up and down, side to side and angled turn.

While machine is working, welding gun is fixed, cylinder will rotate.

Machine is equipped with 1pc SAW welding torch.

2.Japan OMRON PLC is used to control the whole machine. With the help of touch man-machine interface, welding mode and specification can be preset,stored and retrieved. There will be fault alarm and indication during welding process, such as stuck wire, blocked wire, etc.

3. Push-type wire feeder: The wire feeder works stably. Machine is with high welding voltage and slow wire feeding performance, which guarantees reliable arc igniting. Machine is also with low welding voltage and low welding current for filling crater.

4.Cylinder is fixed by the rotary chuck, and supported by bracket of rolling wheels. Universal ball ensures that it is flexible and convenient to load and unload cylinder. Distance between brackets can be adjusted according to cylinder length.

Send product request

Other supplier products

| automatic CO2 welding machines for scaffolding production | automatic CO2 welding machines for scaffolding production 1. Project Layout It includes 6 sets movable torch mechanism(head),12pcs welding torch, 1... | |

| Robot Welding Machine | Single solder wire MIG welding type. The process of MIG welding is a welding process in which an electric arc forms between a consumable wire elect... | |

| 4 axis Automatic Welding Machine for Tipper Trailer | 1. 4axis structure, and welding torch is installed in 4axis structure. Workpiece is fixed in the mould, welding torch will rotate. Welding torch w... | |

| hydraulic cylinder automatic welding machine | Automatic Welding Machine Requirement Complete surfacing circular seam of hydraulic cylinder automatically. With MAG welding process, Machine Featu... | |

| Automatic Solar Tank Welding Machine | Double Circular Seam Welding Machine for Water Heater Perform the automatic welding for the circular seams on the inner tank of water heater. Ensu... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |