automatic CO2 welding machines for scaffolding production

automatic CO2 welding machines for scaffolding production

1. Project Layout

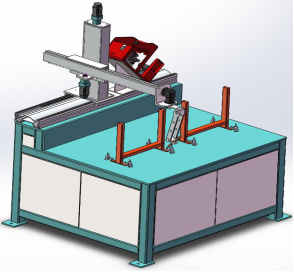

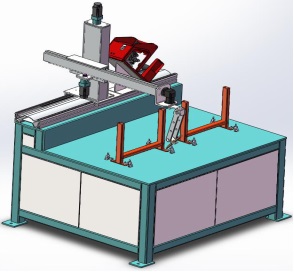

It includes 6 sets movable torch mechanism(head),12pcs welding torch, 12pcs wire feeder, 12 sets power source, 6pcs movable jig,1 set automatically unload devic.

2. Application and Process

Welding machine for 6pcs ringlock and cuplock.

MIG welding type.

Fixing the ringlock components in the jigs by hand, Manually load the pipe. Pipe will be held by rotary chuck.

Spot welding pipe and lock automatically. Machine will finish full welding automatically.

3. Machine Structure

1. There are total 12pcs welding torch for welding circumferential seam. Welding torch can be adjusted up and down, side to side and angled turn.

2. Japan OMRON PLC and torch screen are used to control the whole machine.

3.Push-type wire feeder works stably. crater. .

4.Easy clamping and releasing rotary chuck.

5. Pipe will be fed into welding stage automatically.

Other supplier products

|

|

welding machine for make transformer tank |

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work conti... |

|

|

4 axes robot |

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work conti... |

|

|

Automatic Solar Tank Welding Machine |

Double Circular Seam Welding Machine for Water Heater

Perform the automatic welding for the circular seams on the inner tank of water heater. Ensu... |

|

|

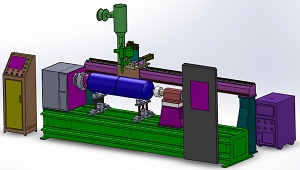

LPG Tank MIG Automatic Welding Machinery |

1.Welding torch can be adjusted up and down, side to side and angled turn. While machine is working, welding gun is fixed, cylinder will rotate. M... |

|

|

Steel Pipe Welding Machine |

1. Welding torch is pneumatically moved in up-down direction. Welding torch can be adjusted up and down, side to side and angled turn. The body of ... |

All supplier products

Same products