SHEET METAL BENDING

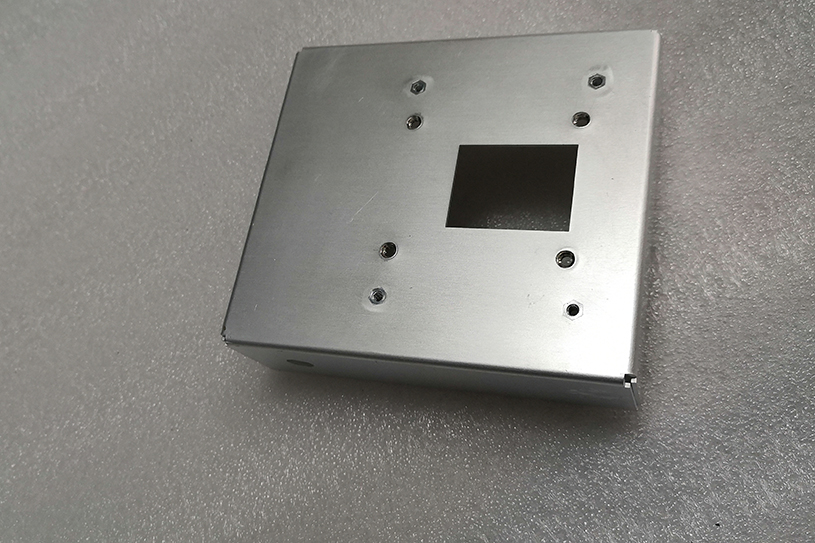

Bending galvanized sheet metalis a process in which a metal sheet is passed through a pressure device and a special mold to transform a flat sheet into a three-dimensional process called bending.

Due to the different materials, thicknesses, lengths, and widths of the plates and the different shapes and angles to be formed, there are bending machines with different tonnage and size pressure equipment, with upper and lower molds of different heights, shapes and V sizes. Special molds with special shapes, such as u bend sheet metal and z bending sheet metal. we have the AIGENI Bending Machine and HRIGEI Bending Machine. Bending is a cold working process. Under the pressure of the upper or lower die of the bending machine, the metal sheet is first elastically deformed and then enters plastic deformation. At the beginning of plastic bending, the sheet is free to bend. The mold or the lower mold presses the sheet material, and the inner surface of the sheet and the lower mold V-groove gradually closes, and the radius of curvature and the bending arm are gradually reduced, and the pressing is continued until the stroke ends, so that the upper and lower molds and the sheet metal are three. The point is close to full contact, and a V-bend is completed at this time, which is commonly known as a bend. Our tolerances are less than 5.0 for sheets of ±0.1 and 5.0 or more for ±0.3.

We are one of the most professionalsheet metal companiesand we provide the sheet metal bending services.

Sheet Metal Bending Materials

SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel

Sheet Metal Bending Custom Solutions

Sending the drawing or your demand to us. Let us know your products’ details and we could offer the sample for you.

If you are looking for a reliable laser cutting manufacturer, HSJcan be your best choice. We have our own designer team and professional service will get back to you. Please contact us at any time.

Send product request

Other supplier products

| Combined Electronic Enclosures | Combined Electronic Enclosures Types: The sheet metal pressing process can be roughly divided into two categories: separation process and formi... | |

| Sheet Metal Stamping | Sheet metal stamping (also known as metal pressing and forming) is the process of placing flat sheet metal in either blank or coil form into a sta... | |

| Bending Forming Box | Bending Forming Box Material of Custom sheet metal boxes To fabricate custom sheet metal boxes, various materials for sheet metal box fabricati... | |

| Machined Enclosures | Material: Carbon Steel/Stainless Steel/aluminum Surface treatment: Paint, powder coat, polish, silk-screen printing, anodize, electronic plate... | |

| Sheet Metal Chassis Parts | Detail Typical products include: Custom Sheet Metal Fabrication, Stainless Steel Fabrication, CNC Laser Cutting Service, OEM Sheet Metal Products... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |