Post Lifting Bin Mixer

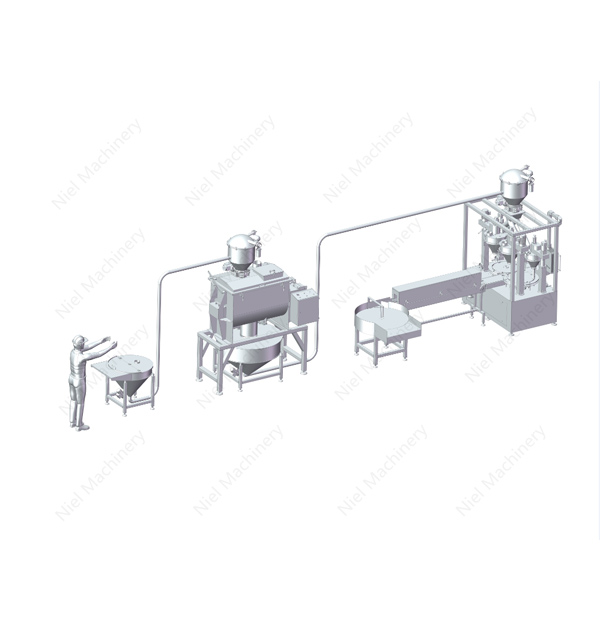

The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid preparation of the pharmaceutical industry.

This model can be fully automated and only needs to input relevant data on the control screen to mix materials.

Product Description of Post Lifting Bin Mixer

Post lifting bin blenderhas functions such as automatic lifting, mixing and lowering. With a hopper mixer and a variety of mixing hoppers of different specifications, it can meet the mixing requirements of multiple varieties and different batches and is the ideal equipment for the total mixing of pharmaceutical companies. At the same time, it is widely used in the pharmaceutical, chemical, food and other industries.

Post lifting blending binmixer is a new type of machine that our company has extensively absorbed and digested foreign advanced technology and successfully developed in combination with national conditions. After the mixing is completed, the hopper can continue to be raised to the process height and is convenient for discharging.

The materials can pass through different process segments in the same container, and do not need to be frequently transferred, fed, etc. Effectively control dust and cross-contamination, reduce material loss, control material stratification, optimize the production process, and fully comply with GMP requirements for pharmaceutical production.

Structural Characteristics of Post Lifting Bin Mixer

The Post lifting bin mixer is composed of a column, machine base, rotation crotch, driving system braking system, control system, etc. Push the mixing hopper into the rotation crotch and lock the nuts. Start the control system to lift the hopper to the mixing height and position it reliably. The driving system will carry out automatic mixing according to the set time, rotation speed and other data. After the mixing operation is finished, the rotation crotch will stop vertically, the hopper will be printed. Loosen the locknuts of the rotary crotch and push the hopper out and transfer it to the next procedure.

Application of Post Lifting Bin Mixer

Milk powder

Foodstuff

Medicinal

Chicken powder

Cosmetic Pigment

Other industries

Main Features of Post Lifting Bin Mixer

(1)The machine has such features as reasonable structure, stable performance, convenient

the operation, no dead corners, and no exposed bolts

(2).The gyrator (mixing hopper) forms an included angle of 30 with the rotation axis. The materials in the mixing hopper rotate along with the gyrator and make tangential movement and achieving the best mixing effect

(3).PLC automatic control is adopted, it is provided with the infrared safety device and the discharging butterfly valve with the misoperation preventer to ensure safe production

Technical Data of Post Lifting Bin Mixer

|

Technical Data |

|||||

|

Model No. |

Effective vol |

Turning Speed |

Total Power |

Length(mm) |

Total Weight |

|

NDJ-200L |

100L |

3-20RPM |

2300 * 1500 * 2000 |

600KG |

|

|

NDJ-300L |

300L |

3-20RPM |

3kw |

2500 * 1900 * 2000 |

1000KG |

|

NDJ-500L |

600L |

3-15RPM |

2800 * 2300 * 2500 |

1500KG |

|

|

NDJ-1000L |

800L |

3-15RPM |

3000 * 2600 * 2500 |

1800KG |

|

|

NDJ-1500L |

1000L |

3-10RPM |

3250 * 2750 * 2800 |

2000KG |

|

|

NDJ-2000L |

1500L |

3-10RPM |

3300 * 2800 * 2800 |

2200KG |

|

|

Power supply |

3P AC208-415V 50/60HZ |

||||

Shanghai NIEL MACHINERY Manufacturing Co., Ltd. specializes in the design and production of bulk powder transportand ancillary equipment. Niel Machinery always puts the interests of its customers first, and the company always adheres to the principle of good faith management. If you want to know more details or want a quotation, just feel free to contact us!

Send product request

Other supplier products

| Semi Automatic Filling Machine | This type of semi automatic pouch filling machinecan complete the measurement, filling and the like, and is suitable for measuring powdery and gran... | |

| Powder Filling Packing Machine | The vertical packing machinerefers to machinery that can complete all or part of the product and product packaging process. The packaging process i... | |

| Conveying Equipment | The conveyor is a machine that frictionally drives the material in a continuous manner. It can be used to form a material conveying process on a ce... | |

| Bucket Elevator | The bucket elevator is suitable for lifting from a low place to a high place. After the material is supplied to the hopper through the vibrating ta... | |

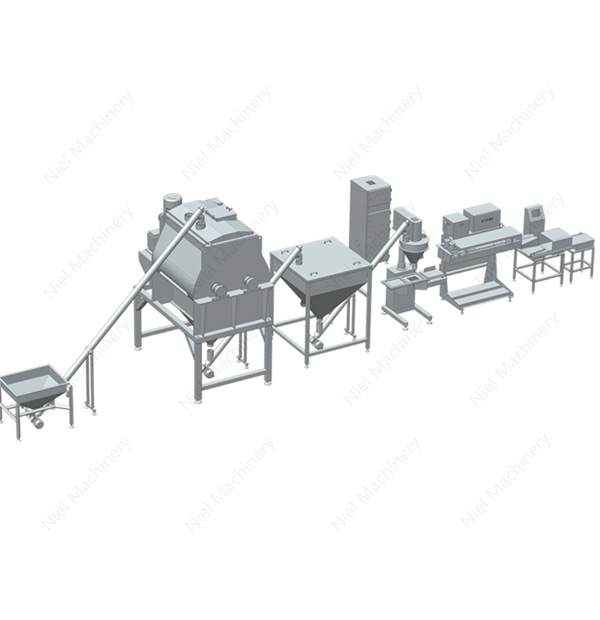

| Powder Mixing And Bag Filling Packing Line | This powder production line is relatively simple in design and is a typical small and medium-sized powder packaging production line. It is suitable... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |