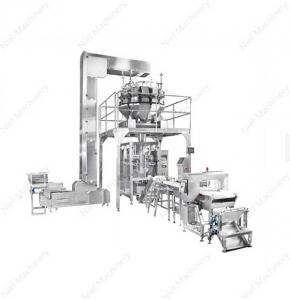

Bucket Elevator

Do you want to buy Bucket Elevator? The mini bucket elevatoris suitable for lifting from a low place to a high place. After the material is supplied to the hopper through the vibrating table, the machine automatically runs continuously upwards.

Product Description of bucket elevator

The conveying speed can be adjusted according to the conveying amount, and the lifting height can be selected as needed. The hopper is designed and manufactured by itself. The PP non-toxic hopper makes the bucket elevator more widely used, and all the dimensions are designed and manufactured according to actual needs, and it is matched with vertical packaging machine, computer measuring machine design, suitable for food, medicine, chemical industrial products, screws, nuts, and other products to enhance the loading, can control the machine's automatic stop by the signal recognition of the packaging machine.

Working Principle of Bucket Elevator

The hopper picks up the material from the underlying storage, as the conveyor belt or chain lifts to the top, turns around the top wheel and then flips down, and the bucket elevator pours the material into the receiving trough. The drive belt of the belt-operated bucket elevator is generally a rubber belt that is mounted on the lower or upper drive roller and the upper and lower redirecting rollers. The chain drive bucket elevator is generally equipped with two parallel drive chains with a pair of drive sprockets on the upper or lower side and a pair of reversing sprockets on the bottom or the top. Bucket elevators are generally equipped with an organic shell to prevent dust from flying in the bucket elevator.

Suitable for lifting from low places to high places, the supply of materials through the vibrating table into the hopper, the machine automatically runs continuously upwards

Application of Bucket Elevator

Food industry

Medicine industry

Chemical industry

Metal oxide powder

Capsules, tablets, pills, small food pellets

Main Features of Bucket Elevator

The deep bucket conveyoris a kind of conveying equipment for vertical lifting materials. It has the advantages of simple structure, low maintenance cost, high conveying efficiency, high lifting height, stable operation, and wide application range.

(1) The driving power is small, and the inflow type feeding, the inducing type discharging, and the large-capacity hopper intensive arrangement are arranged, and there is almost no returning and excavating phenomenon when the material is lifted, so the ineffective power is small.

(2) Wide range of lifting, this kind of hoist has fewer requirements on the type and characteristics of materials, not only can improve the general powdery and small granular materials, but also can improve the materials with high abrasion resistance, good sealing, and less environmental pollution.

(3) The operation reliability is good, the advanced design principle and processing method ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. The lifting height is high. The hoist runs smoothly, so it can reach a higher lifting height.

(4) The service life is long, and the feeding of the hoist adopts the inflow type, and there is no need to use the bucket to excavate the material, and there is little squeezing and collision between the materials. The machine is designed to ensure that the material is less sprinkled during feeding and unloading, reducing mechanical wear.

Maintenance Terms for Bucket Elevator

The bucket elevator should drive at an empty load. Therefore, all materials in the hopper should be drained before each stop, and then parked.

can not be reversed. If the reverse is reversed, the chain derailment may occur, and it is troublesome to eliminate the derailment failure.

Feed evenly. It is forbidden to suddenly increase the feed amount. The feeding amount cannot exceed the conveying capacity of the hoist. Otherwise, it is easy to cause a "smuggling" accident when the material at the bottom is piled up seriously.

Replenish the lubricating oil in time.

When the chain and hopper are seriously worn or damaged, they should be replaced in time.

Shanghai NIEL MACHINERYManufacturing Co., Ltd. specializes in the design and production of powder handling and processing production lines and ancillary equipment. Niel Machinery always puts the interests of its customers first, and the company always adheres to the principle of good faith management. If you want to know more details or want a quotation, just feel free to contact us!

Send product request

Other supplier products

| Double Shaft Paddle Mixer Machine | Dual paddle mortar mixeris also called non gravity mixer machine or twin paddle mixer, it is widely used for drying and mixing of dry powder morta... | |

| Powder Filling Packing Machine | The packing machine refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes ... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... | |

| Laboratory Mixer Machine | The laboratory mixer machine automatically performs all movements such as clamping, rotation, and mixing. Equipped with a series of automatic lifti... | |

| Laboratory Mixer Machine | The mixer for laboratoryautomatically performs all movements such as clamping, rotation, and mixing. Equipped with a series of automatic lifting mi... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |