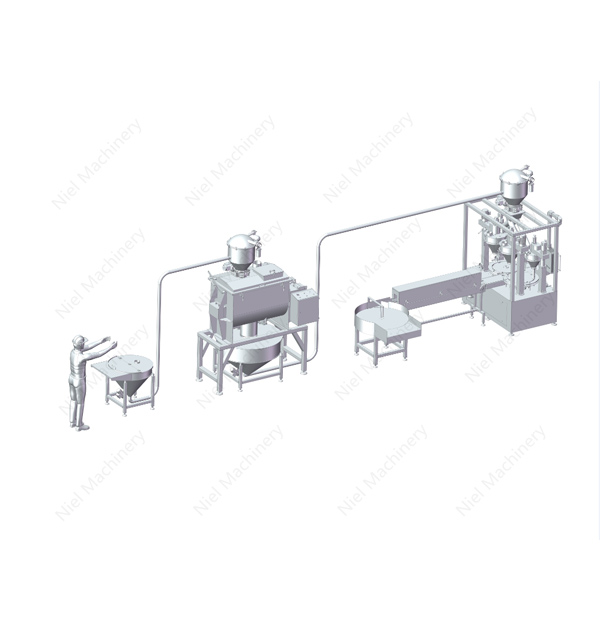

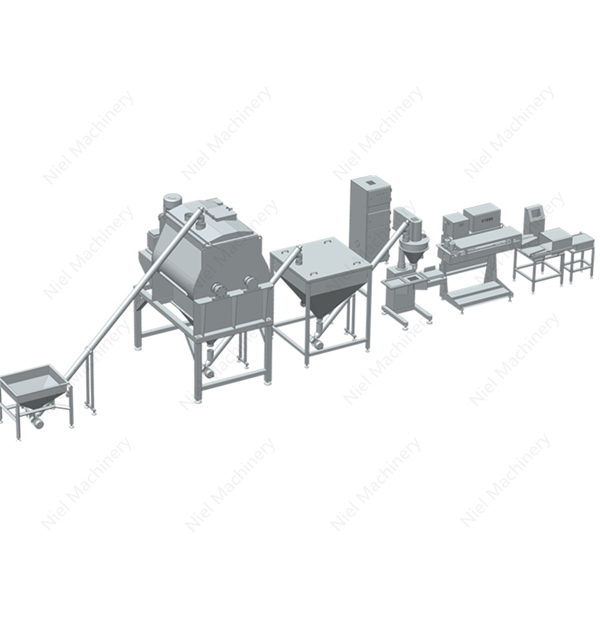

Double Shaft Paddle Mixer Machine

Dual paddle mortar mixeris also called non gravity mixer machine or twin paddle mixer, it is widely used for drying and mixing of dry powder mortar, chemical, pesticide, detergent, pigment food, monosodium glutamate, milk powder, salt, feed, chemicals, ceramics, plastics, rubber additives, and other powders.

Working Principle And Structure Editing of Double Shaft Paddle Mixer

To reduce the replacement cost of the wearing parts of the device, the paddle can be made into two pieces, and a movable small blade can be placed on the blade base to directly replace the worn small blade, which is economical and quick; the discharge form is generally a pneumatic (manual) flap valve, and the arc valve is closely embedded. Inside the cylinder, it is flush with the inner wall of the cylinder, and there is no material accumulation and mixed dead angle phenomenon; the standard type has a large opening door and a small opening door, and the large opening door is opened to the side of the cylinder, and the discharging is clean and fast, and the residue is small.

The machine is equipped with a pair of shafts rotating in opposite directions in a w-shaped mixing chamber, and a blade having a certain angle and a certain number of overlapping shapes is mounted on each shaft, and a fluid layer is formed in the mixing chamber having a certain peripheral speed. The materials in the layer are mixed under the action of the convection mixing principle and are in a state of weightlessness in an instant, thus obtaining a homogeneous mixture. A liquid ejecting port may also be provided above the container for solid-liquid mixing of the sprayed liquid.

The machine's turning speed is 50%-80% of the critical speed. When the blade distance is small, the critical speed can be approached.

Structural Characteristics of Double Shaft Paddle Mixer Machine

The double shaft paddle mixer machine makes full use of the principle of convection mixing, that is, the flow layer is formed by the upper throwing motion of the material in the mixer, and the instantaneous weight loss is generated to achieve the optimal mixing effect state. The horizontal cylinder of the machine is equipped with two-axis rotation. Reverse the paddle, the paddle is at an angle to circulate the material in the axial direction and the radial direction, so that the material is quickly mixed evenly.

Application of Dual Paddle Mixer

Dry mortar

Chemicals, chemicals, detergents,

Feed, pesticides,

Pigment food, monosodium glutamate, milk powder, salt

Ceramic, plastic, rubber additives

Main Features of Double Paddle Mixer

Rotate reversely and throw materials to different angles, mixing time only 1-3 minutes

Compact design and rotated shafts be filled with hopper, mixing uniformity up to 99%

Only 2-5mm gap between paddles and wall, open -type discharge outlet

The patent design ensures the rotating axle discharge outlet wo leakage.

Full weld and polishing process for mixing hopper, W/o any fastening piece like screw, nut

The whole machine is from full stainless steel to make its profile elegant except gear reducer case, direct mechanism, and bearing seat.

Technical Data of Double Shaft Paddle Mixer Machine

|

Technical Data |

||||||

|

Model |

NSJ-300L |

NSJ-500L |

NSJ-1000L |

NSJ-1500L |

NSJ-2000L |

NSJ-3000L |

|

Effective Volume |

300L |

500L |

1000L |

1500L |

2000L |

3000L |

|

Fully Volume |

420 |

650 |

1350 |

2000 |

2600 |

3800 |

|

Loading Ratio |

||||||

|

Turning Speed |

53rpm |

53rpm |

45rpm |

45rpm |

39rpm |

39rpm |

|

Total Weight |

660kg |

900kg |

1380kg |

1850kg |

2350kg |

2900kg |

|

Total Power |

11kw |

15kw |

22kw |

|||

|

Length(L) |

1330 |

1480 |

1730 |

2030 |

2120 |

2420 |

|

Width(W) |

1130 |

1350 |

1590 |

1740 |

2000 |

2300 |

|

Height(H) |

1030 |

1220 |

1380 |

1480 |

1630 |

1780 |

|

Radius(mm) |

277 |

307 |

377 |

450 |

485 |

534 |

|

Power supply |

3P AC208-415V 50/60HZ |

|||||

Shanghai Niel Machinery Manufacturing Co., Ltd. is a professional manufacturer of bulk powder transfer systems, we provide high efficiency cyclone powder dust collector, powder handling cabinet, large paddle mixer, used paddle mixerand etc. Want to buy paddle mixer? Please contact us.

Send product request

Other supplier products

| Conveying Equipment | The conveyor is a machine that frictionally drives the material in a continuous manner. It can be used to form a material conveying process on a ce... | |

| Powder Filling Packing Machine | The packing machine refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes ... | |

| Pulse Jet Dust Collector | This pulse jet dust collectoris a new type of dust collector developed on the basis of our company's first generation dust collector. The stainless... | |

| Powder Mixer Machine | Powder mixer machine is a mechanical device that uniformly mixes two or more materials by mechanical force, gravity, and the like. In the process o... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... |