PIPE SHOT BLASTING MACHINE

Pipe blasting machineor internal shot blasting machineis suitable for any diameter and length of steel pipe cleaning, it can remove the oxide, rust, and scale from welded steel pipe, so that the pipe surface shows metallic colors.

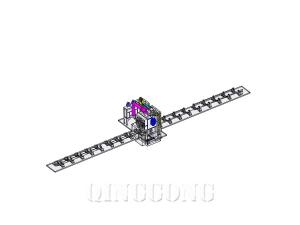

Pipe outer wall shot blasting machine

pipe shot blasting machine 1

Pipe outer wall shot blasting machine, also known as the diabolo shot blasting machine.

steel pipe moves through the machine on skew roller conveyors. Such form of the conveyor provides simultaneous rotation and transition movement of the pipes through the machine, which can achieve evenly blasted surface. KT series turbines made from wear-resistant materials, with power from 5.5 to 45kw provide efficient and quality shot blasting. The shot blasting part of the machine’s robust housing is protected by wear-resistant shields made from manganese steel. Entry and exit seals chamber with a series of rubber screens keep the abrasive inside the machine. Screw conveyor, an elevator and sand cleaner provide returning and continuing cleaning of the abrasive. Standard pipe blasting equipmentincludes PLC Siemens, display, automatic or manual mode, automatic start-up of turbines, working-hours counter, variable frequency drive of the cylinder drive, etc. Machines may be built into highly productive lines for basic color application, including drying chamber, automatic coloring chamber and drying tunnel.

pipe shot blasting machine 2

Pipe Shot Blasting Machine Parameter:

|

ITEM |

ST500 |

RT800 |

RT15000 |

|

Dimension of pipe(Dia.×L) (mm): |

Φ(50-500)× |

Φ(150-800)× |

Φ× |

|

Wheel conveyor speed (kg): |

1 to 3 |

1 to 3 |

1 to 3 |

|

Number of blast wheels and power (kW): |

2×15 |

2×15 |

2×30 |

|

Material of table: |

Manganese |

Manganese |

Manganese |

|

Ventilation requirements (m3/h): |

5000 to 7000 |

8000 to 14500 |

|

|

Material of Protective lining |

Manganese/Cast alloy |

Manganese/Cast alloy |

Manganese/Cast alloy |

|

Material of blast chamber |

Mild steel |

Mild steel |

Mild steel |

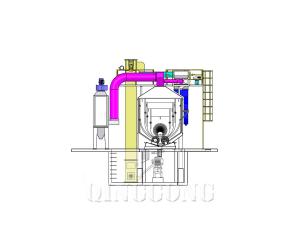

Pipe inner wall shot blasting machine

A complete system includes Moveable Front and rear Chamber, Left & Right Hydraulic Moveable Blast Wheel, Belt conveyors, Bucket Elevator, Platform, Abrasive Separator, Dust Collector, Blast Wheel Moving Mechanism, Hydraulic Loading, and Unloading System and Control Panel.

We design the loading mechanism as Inclined Rail Type. When the pipe reaches to the work position, the moveable sealing chambers move inside droved by the cylinder. Both of the ports of the pipe are sealing. Then start the dust collector system, abrasive recovery system, and moveable blast wheel. The large airflow dust collector system we designed not only can dedusting but also recovery the abrasive during the blasting operation. After finish, off the feeder and blast wheel, then the moveable blast wheel mechanism out the pipe. The moveable sealing chambers move outside. Pull out the pipe used the pull mechanism on the trolley, then the pipe roll down the unloading conveyor automatic. There also have a vacuum recovery machine at the unloading conveyor to the abrasives remnant in the pipe. One operating cycle is finished.

Shot Blasting Machine

QINGGONG MACHINERY shot blasting machineoffers you an effective solution to deal with the surface of the workpieces, including remove the contaminant on the surface, clean and roughen a smooth surface before applying a primer or coating to the workpiece. More specifically, the treatment of a shot blasting machine includes derusting, descaling, desanding, or deburring of the workpieces. Other uses are such as surfaces shot peening, finishing and roughening of surfaces so as to make coat better.

Send product request

Other supplier products

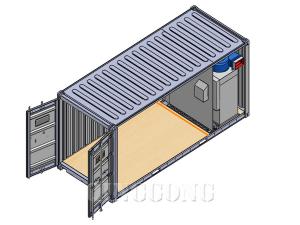

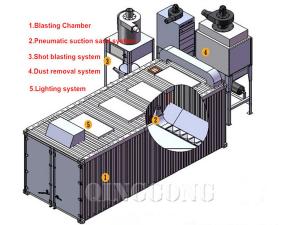

| TRANSPORTABLE CONTAINER BLAST ROOM | The movable sandblasting room or portable blast room, abrasive recovery system, dust collector, portable shot blasting machinetogether, it can be t... | |

| SPARE PARTS | KT series high performance turbines have shot blasting machine sparesparts including blasting wheels provided with eight throwing blades locked int... | |

| CONTINUOUS TUMBLE PASS-THRU SHOT BLAST MACHINE | The through-feed blast cleaning process offers a number of distinct advantages and ensures efficient and cost-effective blast cleaning. Continuous ... | |

| AIR BLAST ROOM | Air blasting room or Air blasting cabinet with pneumatic media reclaim system – An economical alternative, vacuum reclaim systems utilize cyc... | |

| PIPE SHOT BLASTING MACHINE | Pipe shot blasting machineor steel pipe shot blasting machineis suitable for any diameter and length of steel pipe cleaning, it can remove the oxid... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |