Casting

Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting metal preparation, mold preparation, and casting processing. Casting metal refers to the metal material used for casting castings in the production of castings. It is an alloy in which metal elements are the main components and other metals or non-metal elements are added. It is usually called casting alloy, which mainly includes cast iron, cast steel, and cast non-ferrous alloy. As a professional casting company, ECTN provides our clients with advanced metal casting servicessuch as low and high-pressure aluminum casting, custom aluminum casting, custom brass casting, permanent mold aluminum casting and etc.

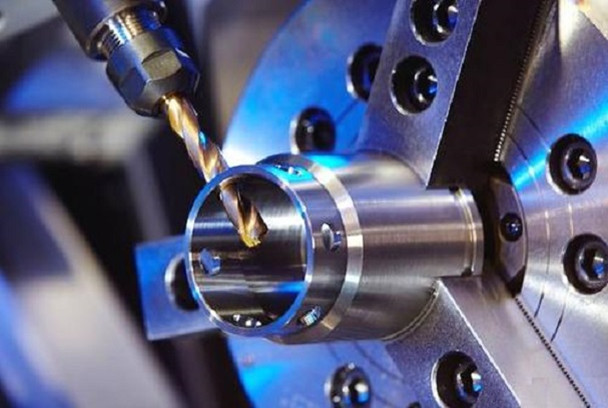

Die Casting

The product uses die-casting process to complete the blank, CNC machining and polishing treatment, suitable for auto parts.

Gravity Casting

The product is a casting product, which is used to fix the support of the driven shaft. The surface is not machined and has no holes and cracks.

Processable Materials for Casting

Copper

Magnesium

Stainless Steel

Carbon Steel

Alloy Steel

Zinc Alloy

Aluminium Alloy

ABS

Aceta

Acrylic

Carbon Fibe

Fiberglass

Nylon

Polycarbonate

Spring Steel

PTEF

PVC

Neoprene

Polyethylene

Polypropylene

Polystyrene

Rubbe

Silicone

NBR

Advantage of Casting

It Can Produce Parts With Complex Shapes, Especially Blanks With Complex Cavitie

Wide Adaptability, Metal Materials Commonly Used In Industry Can Be Cast, From A Few Grams To Hundreds Of Tons.

The Shape And Size Of The Casting Are Very Close To That Of The Parts, Reducing The Amount Of Cutting, Which Is Non-cutting.

It is Widely Used

40%~70% of agricultural machinery and 70%~80% of machine tools are castings.

Casting FAQs

Casting Cracks

The solution: Use low-strength investment materials, reduce the casting temperature of the metal as much as possible, and do not use alloys with low ductility and brittleness.

Easy To Crack When Die-casting Thin-walled Products

If this problem occurs, it may be due to material problems or poor mold opening or improper selection of process parameters. Try to control the proportion of waste not to exceed 30%. The mold retention time should not be too long, about 3s per mm of wall thickness, and ejection delay is not allowed. Long, generally 0.5-2s.

Metal Splashing During Die Casting

Reinstall the mold; increase the clamping force and adjust the die-casting machine to keep the movable and fixed mold mounting plates parallel to each other; add a support plate on the movable mold to increase the rigidity of the sleeve plate.

Why Can't The Inner Processing Of Aluminum Die-casting Hole Exceed 0.25mm

In order to be suitable for die casting, people add a lot of silicon to the aluminum alloy used for die casting. When the aluminum alloy condenses in the mold, the silicon will float on the surface to form a layer of silicon film that is very hard and wear-resistant. Some OEM designers use this feature to directly design the inner surface of the die casting hole as a bearing surface. This silicon surface layer is generally only 0.2 to 0.9 mm thick. With too much processing, the life of the bearing surface will be shortened.

Unclear Marking During Casting

ETCN is a professional precious metal casting companies, titanium casting companies, iron casting companiesand machining company. We provide CNC Machining, Casting, high pressure aluminum casting, low pressure aluminum casting, vacuum pressure casting, sand casting and die castingand so on. Want to know about aluminium casting price? Please contact us.

Send product request

Other supplier products

| Casting | Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting ... | |

| Machining Service | 20 YEARS Professional CNC Machining Service Company ETCN was established in September 2008. After years of accumulation and development, it has... | |

| Stretch Forming | Sheet metal stretch formingis a technology to stretch the mental into different shaped mental parts. It also will improve the structure of the unlo... | |

| CNC Milling | CNCmilling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, mul... | |

| Precision Machining | As a precision machining cnccompany of china, ETCN offers cost-effective precision machining solutions whether you need a single part, a batch of p... |

Same products

| Shoes Flexing Tester | Seller: Qinsun Instruments Co., Ltd | It's used for determining the flexibility resistance and or indicating the cracks od shoe or shoe... | |

| Shoelace Abrasion Tester | Seller: Qinsun Instruments Co., Ltd | Application: This shoelace abrasion tester is used for shoelace against standard eyelet abrasion... | |

| Heel Fatigue Tester | Seller: Qinsun Instruments Co., Ltd | Heel Fatigue Tester is used to determine the resistance of medium and high heels of ladies’... | |

| Heel Impact Tester | Seller: Qinsun Instruments Co., Ltd | Heel Impact Tester is used to determine the impact strength of heels of ladies’shoes. Ap... | |

| Ross Flex Tester | Seller: Qinsun Instruments Co., Ltd | Whole Sole ROSS Flexing Tester GT-KB05D To determine right angle flexing risistance for whole sol... |