CNC Machining Center

We strive to continuously introduce advanced technology to the industry and deliver by working closely with our CNC machine tool manufacturers. We are focused on developments to increase quality and best lathe machinefor our customers. Sincerely welcome to visit our company or contact us for cooperation.

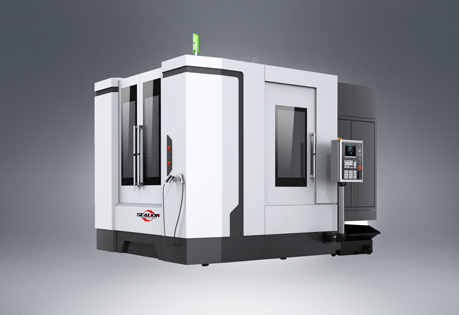

From the vertical type and horizontal type to gantry type, Sealion Machine Tool offers you a wide range of CNC Center. With our hard-working design engineers, we always keep our high speed machining centerabove other manufactures. Those machines are widely used in mold processes, general machining, and massive production area. It can be singly used and can be used for multiple operations on parts in a production line. Those machining centers are powerful, high-speed positioning, mechanical and electrical integration, and equip with automatic chip conveyor. Please talk to our professional engineers for selecting the best CNC precision machining, high precision cnc machine industrial, and high-speed cnc equipment.

Cnc Machining Center For SaleWorking Principle

After the workpiece is clamped in the machining center for sale, the CNC system can control the cnc milling tools according to different machining processes, automatically select and replace the cnc milling machine tools, automatically select the speed of the machine spindle, the feed speed, the motion path of the tool relative to the workpiece, and other auxiliary functions and machining a workpiece can be accomplished in multiple processes. It has a variety of cutters or cutter selection functions, which greatly improves the production efficiency.

Due to the centralized and automatic tool change process, the cnc machining chinacenter reduces the clamping of the workpiece. Measurement and machine tool adjustment time make the cutting time of the machine tool reach 80%% of the machine start time (ordinary machine tool is only suitable for 15 times). It also reduces the working process turnover, loading and unloading and storage time between workpieces, shortening the production cycle, and has obvious economic benefits. The cnc milling center is suitable for small and medium batch production with complex shapes, high precision requirements, and frequent product replacement.

Benefits of Cnc Machining Center

Turning Center vs Machining Center

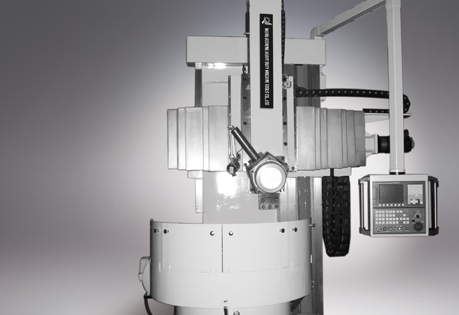

Traditional turning center have a horizontal structure. It has a main shaft and a workpiece placed parallel to the floor. The spindle is installed on the spindle box facing the tailstock, which is located at the other end of the worktable. On the other hand, machining centers tend to have a vertical style. It has a workpiece fixing system installed on the base of the machine tool, and a cutting tool suspended above the worktable for machining the workpiece from the top.

Likewise, these modern CNC machines usually have multi-axis machining capabilities, which allows them to cut workpieces at different angles and in different directions. In order to integrate all functions into one machine, the style of the turning center and the machining center has evolved into a booth-like chamber containing all electric tools. Since the turning center follows the basic design of the lathe, the length of the machine tool may be larger than that of the machining center.

Send product request

Other supplier products

| Horizontal Machining Center | CNC horizontal turning centersparts can automatically finish four sides milling, boring, drilling, expanding, reaming, tapping, and other multicoat... | |

| Slant Bed CNC Lathe | As a reliable machine tools company, our company culture is centered around our motto "Customer Service, Customer Support, Customer Choice". We str... | |

| Horizontal Lathe | Sealion Machine Tool supplies a wide range of horizontal lathe. CNC type or conventional type, flat bed or slant bed, horizontal turning lathe, hor... | |

| Single Column Vertical Lathe | Conventional Single Column Vertical Lathe Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It makes the machine bette... | |

| Gantry Machining Center | SEALION supplies Gantry Machining Center both tables moving type or gantry moving type. Gantry type vertical machining centeris widely used in the ... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |