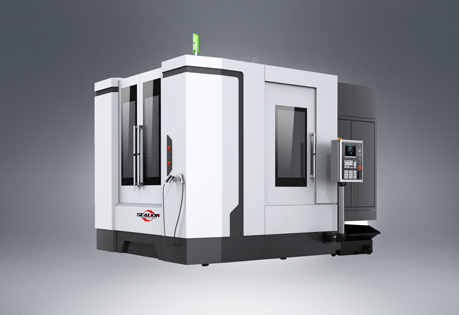

Horizontal Machining Center

CNC horizontal turning centersparts can automatically finish four sides milling, boring, drilling, expanding, reaming, tapping, and other multicoated processes after one clamping. Talk to our engineers, you will find the best solution.

Features of horizontal boring and milling center

This series horizontal machining center for saleis developed and manufactured in sealion machine tools. It is advanced and leading products in China for general machining purposes.

The machine is widely used in the processing of box parts, shell parts, disc parts, and special-shaped parts in aerospace, automobile, die, and machinery manufacturing industries. The parts can automatically finish four sides milling, boring, drilling, expanding, reaming, threading, and tapping after one clamp.

How does Horizontal Machining Center Work?

CNC control

Although the machining tasks completed in the horizontal machining center are more complex and critical, through quick and simple settings, sequential commands can be executed through CAD files.

Basic structure

As the name suggests, horizontal machining center uses a main axis parallel to the ground. The horizontally oriented spindle operates the tool extending outward from the side of the tool holder to remove material from the side of the metal part. During the cutting process, metal shavings will be generated and fall off the workbench.

The horizontal machining center rotates the cutting bit against the surface of the stationary workpiece. Unlike operations, turning centers rotate workpieces instead of tools in turning applications. Depending on the application, the cutting tool rotated by the spindle in the HMC can remove material at high speed or slowly and slightly.

Although HMC is suitable for materials such as aluminum, steel, copper and even plastics, the characteristics of the material and the chips generated during the cutting process should be considered to optimize the processing technology and reduce wear.

Milling cutter

The rotating tools of these CNC machining centers perform high-precision milling and other machining operations along the rotating axis to add additional functions. Speaking of milling cutters or end mills, they are produced with teeth and grooves, and they are sharp cutting edges determined by the contour of the product. The material, helix angle and running speed of the milling cutter are important factors that affect the actual milling performance.

Horizontal Machining Center VS Vertical

Both horizontal machining centers and vertical machining centers are popular metal processing solutions and are widely used in workshops. Two styles with different directions from the main axis have their own advantages. When choosing between the two, the number of sides to be cut and the shape of the product are key. In short, if the product needs to be processed on more than two sides, horizontal machining center will be a better choice than vertical machining center.

Vertical machining center is a more economical choice. If you only want to add features on one side of the part, a solution that requires fewer workpiece fixtures and fixtures can provide simpler and more familiar operations. Vertical machining centers are large enough to handle heavy loads and the largest parts, but they can also be used to machine tiny parts, such as medical bone plates.

As mentioned earlier, horizontal machining centers are more advantageous for applications that require multi-sided machining. The 2 integrated trays that normally hold the fixture allow access to the front and side of the part. This feature eliminates human error and significantly improves productivity. Compared with vertical machining center, another advantage of horizontal machining center is the larger tool magazine tool holder, which can improve the chip flow and can hold up to hundreds of tools.

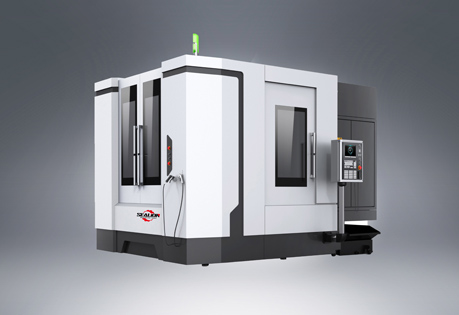

Advantages of Horizontal Machining Center

High Accuracy-advanced thermal control system with a hollow cooling system.

High Speed-12000rpm top spindle speed, 54000mm/min fast-moving speed.

High rigidity- best HT250 casting for the machine body.

As one of the cnc horizontal machining center suppliers, we provide horizontal boring mill, china cnc lathe services, cnc horizontal machining center for sale, machining centers for boring milling turning, horizontal machining center vs vertical, lion machineand etc. Want to knowmoreabout horizontal machining center axis directions?Please contact us.

Send product request

Other supplier products

| Slant Bed CNC Lathe | As a reliable machine tools company, our company culture is centered around our motto "Customer Service, Customer Support, Customer Choice". We str... | |

| Horizontal Machining Center | cnc horizontal turning centers parts can automatically finish four sides milling, boring, drilling, expanding, reaming, tapping, and other multicoa... | |

| Flat Bed CNC Lathe | China flat bed cnc lathecan turn large axle parts and disc parts with various kinds of threads, arcs, cones, end faces and inner and outer surfaces... | |

| 7.Vertical Lathe | Looking for the best deal of machine tools? You are here in the right place. Sealion is one of the CNC machine tools companywho can always help you... | |

| Floor Type Boring Mill | Floor type 5 axis milling machine is suitable for large size jobs to do milling, boring, drilling, etc. The floor type boring and milling machine i... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |