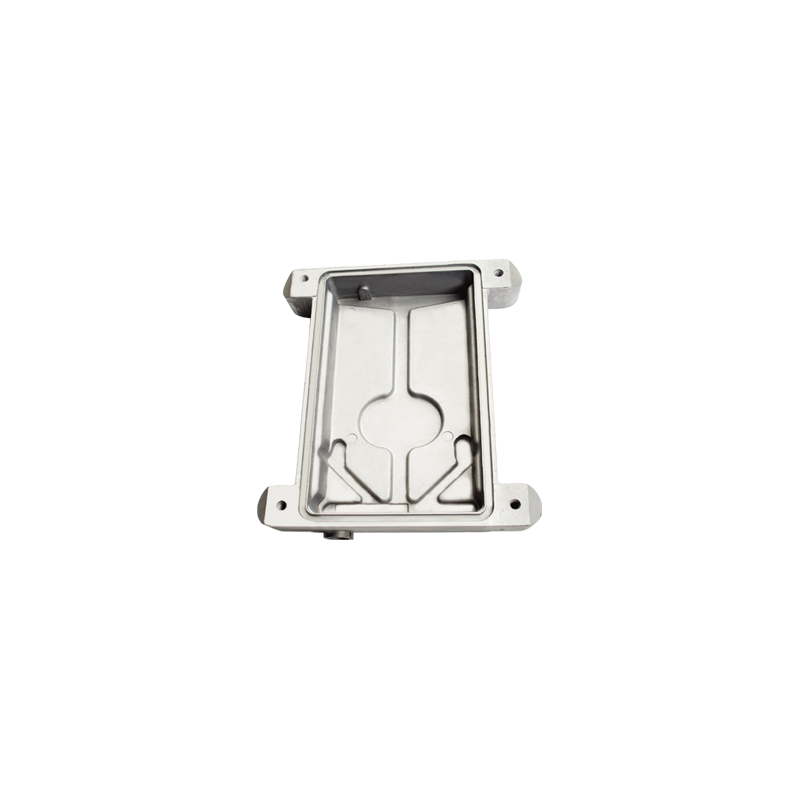

CNC TURNING PARTS

Ningbo Hewcho Industrial is an ISO:9001 and ISO/TS16949 certified company dedicated to manufacturing superior-quality Precision turned parts Chinaand custom CNCaluminum partsto customer specifications. With a strong focus on continual improvement, our company only utilizes best-practices to ensure that the work we do for our customers is done in the most efficient, precise and cost-effective way possible.

CNC turning parts are components and workpieces with a high degree of dimensional accuracy and are produced in a wide variety of shapes and sizes. The production takes place on CNC-controlled lathes, with the setting of the cutting parameters being numerically coded. So recurring machining processes can be retrieved as often as you like. Profitable is the production of CNC turned parts, especially in series production, where large quantities of consistent quality without retooling or maintenance must be made. The materials used are metals such as aluminum or stainless steel and carbon steel. So CNC turning machine parts are associated with a high due to the economic manufacturing process quality has become important components of many products. Whenever something is spinning or moving, a CNC precision turning componentsis often behind it. Typical applications of CNC precision turned parts are mechanical engineering, electrical engineering, the automotive industry and many more.

How is the production done during CNC turning?

Ningbo Hewchois one of the CNCturned components manufacturers, CNC turning has become an indispensable basic technology in the field of manufacturing technology today. This is also illustrated by the market share of the CNC lathes produced in the total value of the worldwide produced metal cutting machine tools. The "CNC" stands for Computerized Numerical Control, which stands for the computer-controlled machining of turned parts. The parts to be manufactured are developed in advance using simulation software on the PC and then transmitted to the lathe via a network. These high-tech machines have more than two Machining axes. In this case, the workpiece carries out the main cutting movement with its rotation and the lathe tool clamped in the chuck is guided along the rotating workpiece with a carriage in order to lift a chip. The entire production is automated and monitored by sensors, which is why large quantities can be produced with consistent quality.

Production spectrum on the turned parts marketplace

|

Turning Process |

Range of Parts |

Material |

Certification and Quality |

|

CNC Turning |

Small, Medium series |

Carbon Steel |

Most modern CNC measuring technology |

|

Automatic Turning |

Short and long turned parts |

Aluminum |

Creation of logs |

|

Precision Turning |

Precision Parts |

Brass |

Own measuring rooms |

|

Hard Turning |

Turned parts in assemblies |

Stainless Steel |

SPC documentation |

|

Wage Turning |

Alloy Steel |

ISO9001:2008 |

|

|

Conventional |

Copper |

ISO/TS16949 |

Send product request

Other supplier products

| Hydraulic Brake Hose Fittings | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Hydraulic Brake ... | |

| Carbon Steel CNC Milling Parts | Ningbo Hewcho Industrial is an ISO:9001 and ISO/TS16949 certified company dedicated to manufacturing superior-quality Precision turned parts Chinaa... | |

| Swiss CNC Turning Components | Features ofswissTurned parts: ·Product name: Swiss CNC Turning Components·Material: Carbon Steel, Stainless Steel, Alloy Steel, Brass... | |

| CNC Turning Sleeve Bushings | Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Information About HEWCHO CN... | |

| Alloy Steel CNC Machining Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Features of All... |

Same products

| industrial sewing machine spares | Seller: Zhejiang Huaqi Information Technology Co., LTD | Our spares are made from robust materials that can withstand the rigors of continuous use in indu... | |

| Flat End Type of Thread EndSuction Machine | Seller: Qinsun Instruments Co., Ltd | lt is applicable to clean up thread endand fibre dust (no static electricity) cutdown from garmen... | |

| Fabric Friction Electric Charge Density Tester | Seller: Qinsun Instruments Co., Ltd | FFriction Charging Tester is the antistatic fabric and knitted fabric friction generated by the a... | |

| Mask Air Exchange Pressure Difference Tester | Seller: Qinsun Instruments Co., Ltd | Medical face mask differential pressure tester also called mask breathility tester is to determin... | |

| Face Mask Tensile Testing Machine | Seller: Qinsun Instruments Co., Ltd | Application: This Masks Universal Tensile Strength Tester is designed for conduct tensile, compr... |