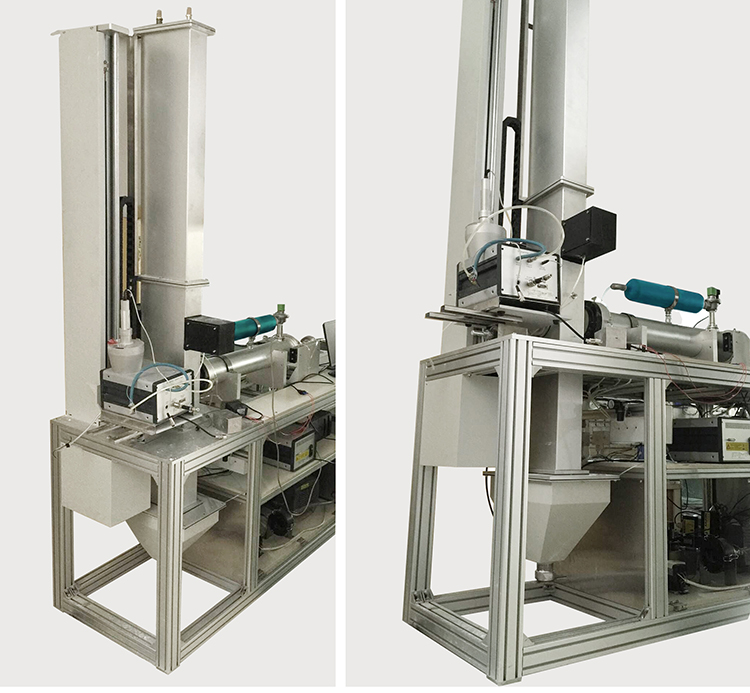

Fabric Friction Electric Charge Density Tester

FFriction Charging Tester is the antistatic fabric and knitted fabric friction generated by the amount of charged charge test equipment, used to measure the amount of static electricity charge.This equipment is used to determine the electrostatic characteristics of friction-charged fabric under lab conditions。

Standards:

JIS L-1094;

JIS T-8118;

ZB W 04008-89;

GB / T12703.2-2009;

GB 12014-2009;

GB / T23316-2009

Specifications:

Electrostatic charge test range: 0-2uc, accuracy: ±0.001uc

Nylon or acrylic friction cloth size: 400mm×450mm

Sample size: 250mm×350mm,each 3pcs in vertical & zonal

Running condition: Running time 5min, roller inside temperature: 60±100C

Rolling friction machine specs:

| Term | Spec | Term | Spec |

| Roller dia. | ≥460mm | Roller dia. | ≥280mm |

| Depth | ≥350mm | Roller rotation rate | ≥45r/min |

| Vane number | 3 | Roller liner material | Nylon, polypropylene standard cloth |

| Heating mode | Electric heating | Exhaust capacity | ≥2m3/min |

| Others | Double-sided tape with sample in-out place | ||

Friction Charging Tester Main accessories:

Voltage meter (R8240): 1 set

Capacitor: 1 set

Cable (A01009-200): 1 root

Connection cable (A01009-50): 1 root

Power supply-type strip in addition to the electrode: 1 root

Friction abutment / ground pad (nylon friction cloth): 1 set

Insulated rods (20Φ x 500L mm acrylic clear fiber): 1 root

Certificate of proof of voltage meter (traceability): 1 book

Friction Charging Tester Note:

1, the system of Faraday tube outer cylinder should be reliably grounded.

2. Clear the charge amount measurement unit before each measurement.

3, the measured object must be measured from the power supply.

4, before the test, please turn on the power switch to make the machine warm up for 15 minutes.

5, voltage / current generator is not to sell goods.

![]()

Loading