Dry Ball Mill

Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and other building stones, or products that require storage and sales in the form of powder. In addition, if the concentrator is located in an arid area and water resources are scarce, dry ball mill can be used for water saving.

Advantages of Dry Ball Mill

Dry ball mill need less water, which greatly saves water consumption compared with wet ball mill.

The material produced by dry ball mill is the finished product.

The efficiency of dry ball mill is higher.

Advantages of Dry Ball Mill

Working Principle of Dry Ball Mill

The dry ball mill is a horizontal cylindrical rotating device, which is driven by outer gear. It is divided into lattice type dry ball mill and multi-bin type dry ball mill. The material enters into the front bin of the mill through the feeding device, and the hollow shaft screw evenly enters into the front bin of the mill. There are stepped lining plates or corrugated lining plates in the bin, which are filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall down, which has a heavy impact and grinding effect on the material. After rough grinding in the front bin, the materials enter the second bin through a single-layer partition board. The bin is inlaid with a flat lining board and steel balls to further grind the materials. The powder is discharged through the discharging grate plate to complete the grinding operation.

Main Structure of Dry Ball Mill

lFeeding screw for feeding raw material.

lThe shell is equipped with a manhole for maintenance and replacement of the inner liner.

lDischarge part for ball mill to discharge qualified products.

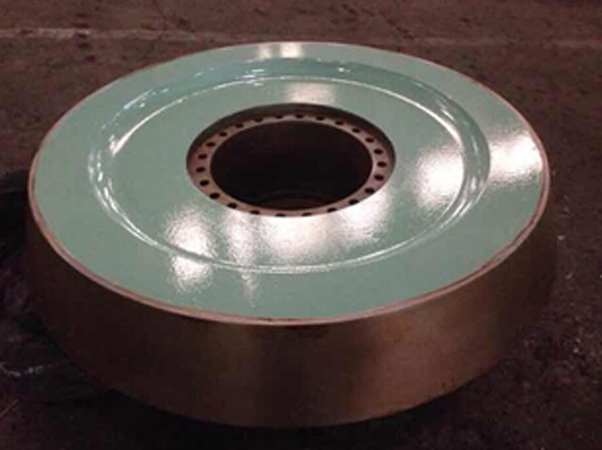

lMain bearing.

Transmission part.

Operation and Maintenance of Dry Ball Mill

Before the ball mill is started, check whether the connecting bolts are tightened, including gears, couplings, etc. Check whether the oil tank and reducer have enough quantity; Whether the whole lubricating device and instrument are defective and whether the pipeline is smooth. Finally, check whether there are any sundries around the overflow ball milland classifier. Only if everything is clear can we get the ball mill to work.

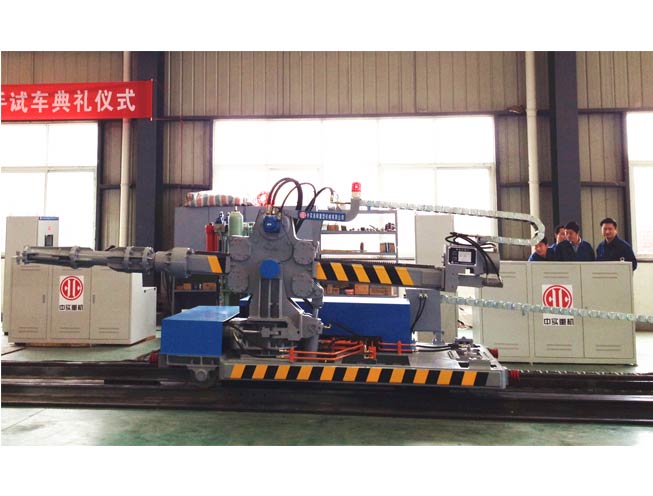

Intelligent Grinding Expert System Ball Mill

To realize the intelligent control for ball mill operation, as one of heavy equipment dealers, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient.

Technical Parameters of Dry Ball Mill

|

Specification |

Capacity |

Rotary Speed |

Input Size |

Grinding Medium Load |

Volume |

Motor |

Profile Dimensions(L×W×H) |

Total Weight |

Remarks |

|

|

m |

t/h |

r/min |

mm |

t |

M3 |

Power/kw |

Voltage/V |

mm |

t |

|

|

φ2.2×6.5 |

15-16 |

22 |

<20 |

22 |

18 |

320 |

6000 |

52 |

||

|

φ2.2×8 |

30 |

<25 |

45 |

560 |

6000 |

81 |

||||

|

φ2.2×13 |

29-30 |

<25 |

60 |

43 |

630 |

6000 |

||||

|

φ2.2×13 |

24-35 |

<25 |

60 |

43 |

630 |

6000 |

113 |

|||

|

φ2.2×13 |

40 |

<25 |

65 |

50 |

800 |

6000 |

145 |

|||

|

φ3×9 |

36-42 |

<25 |

70-80 |

1000 |

6000 |

|||||

|

φ3×11 |

60-65 |

<15 |

90-100 |

69 |

1250 |

6000 |

180 |

|||

|

φ3.2×7+1.8 |

48-63 |

18 |

<20 |

55-58 |

1000 |

6000 |

||||

|

φ3.4×7+1.8 |

54 |

<20 |

65 |

1000 |

6000 |

(22.057+a)×5.12×4.23 |

a is the length of the motor |

|||

|

φ3.4×7.5+1.8 |

~60 |

<20 |

70 |

1250 |

6000 |

214-217.5 |

||||

|

φ3.5×10 |

75 |

<20 |

80 |

1250 |

6000 |

270 |

||||

|

φ3.5×9 |

90-95 |

<15 |

130 |

94 |

2000 |

6000 |

||||

|

φ3.8×8.5+3.5 |

~90 |

<20 |

100 |

1600 |

6000 |

|||||

|

φ4.8×8.5+3.5 |

150 |

15 |

<20 |

150 |

2800 |

|||||

|

φ4.6×10+3.5 |

190 |

15 |

<25 |

190 |

157 |

3550 |

352 |

|||

|

φ4.6×9.5+3.5 |

185 |

<25 |

175-180 |

148 |

3550 |

6000 |

293 |

|||

|

φ4.6×14 |

185-220 |

15 |

210 |

185 |

4200 |

310 |

||||

Send product request

Other supplier products

| Industrial Centrifuge Machine | Centrifugal concentrator is a kind of equipment for gravity separation of ore particles in a centrifugal force field, which is one of the high-effi... | |

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust rollerused in rotary kilns, rotary type driers and so on. CIC has been speci... | |

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... | |

| Furnace Tapping Machine | We developed the discharge furnace robotic arm, based on the working process and tools of manual operation of slag port opening and closing of the ... | |

| Vertical Centrifuge | The vertical centrifuge machine is made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmis... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |